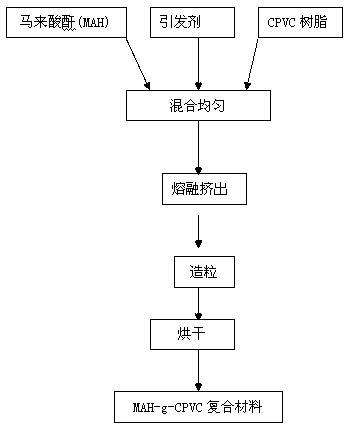

Preparation method of maleic anhydride grafted chlorinated polyvinyl chloride composite material

A technology of chlorinated polyvinyl chloride and maleic anhydride is applied in the field of modification of chlorinated polyvinyl chloride (CPVC) composite materials, which can solve the problems of poor impact resistance, thermal decomposition, and difficult processing, and has wide application prospects. Effect

Active Publication Date: 2013-05-01

HARBIN ZHONGDA PROFILE TECH

View PDF6 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the melting temperature of CPVC resin is close to or exceeds its thermal decomposition temperature, and it is easy to cause overheating and decomposition during the process of forming products, which makes the processing difficult, and the products are brittle and have poor impact resistance, which makes the chlorinated polyvinyl chloride (CPVC) material. Applications are very limited

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a modified technique of chlorinated polyvinyl chloride (CPVC) composite material, in particular to a preparation method for producing maleic anhydride grafted chlorinated polyvinyl chloride (MAH-g-CPVC) composite material by adopting a melting method to graft the maleic anhydride (MAH) onto a CPVC molecular link. The thermal decomposition temperature is 15 to 20 DEG C higher than that of ordinary CPVC resin, so that a melting processing temperature condition is satisfied, the Vicat softening temperature of the material can reach 125 to 135 DEG C, the maximal application temperature can reach 120 DEG C, and the long-term application temperature of the material is 105 DEG C. The defects that the melting temperature of the CPVC is close to or exceeds the thermal decomposition temperature, the overheating decomposition is likely to occur in the process for machining and forming a product, the machining difficulty is large, the fragileness of the product is large, and the impact resistance is poor can be overcome, so that the application prospect of the CPVC is wider.

Description

technical field [0001] The invention relates to a modification technology of chlorinated polyvinyl chloride (CPVC) composite material, in particular to a method for preparing maleic anhydride grafted chlorinated polyvinyl chloride (MAH-g-CPVC) composite material by melting method Methods. Background technique [0002] Chlorinated polyvinyl chloride (CPVC) plastics have excellent physical and chemical properties such as heat resistance, weather resistance, chemical medium corrosion resistance, colorless, tasteless, odorless and flame-retardant self-extinguishing properties. It is a fast-growing application field in recent years. The novel plastic material has great market potential. Chlorinated polyvinyl chloride (CPVC) materials can be made into pipes, profiles, plates, rods and other products through molding and processing, and are mainly used in chemical industry, electrical industry, interior decoration industry, petroleum industry, construction industry and other fi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L51/00C08F259/04C08F222/06C08F114/06C08F8/22B29C47/92B29C48/92

CPCB29C48/04B29C48/92B29C2948/9259B29C2948/92704B29C2948/92885B29C2948/92895

Inventor 胡大忠张文龙冯伟刚戴亚杰韩克伟胡淼

Owner HARBIN ZHONGDA PROFILE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com