Supercritical fluid technology coating modifying technique of ammonium nitrate

A technology of supercritical fluid and ammonium nitrate, which is applied in the production of bulk chemicals, fertilizer mixtures, explosives, etc., and can solve problems such as ultrafine ammonium nitrate coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1, a supercritical fluid technology coating modification process of ammonium nitrate, mixing a certain amount of AN with acetone (mass ratio 1:0.8) for closed grinding, after 10 minutes, the particle size of AN is 2-10 μm.

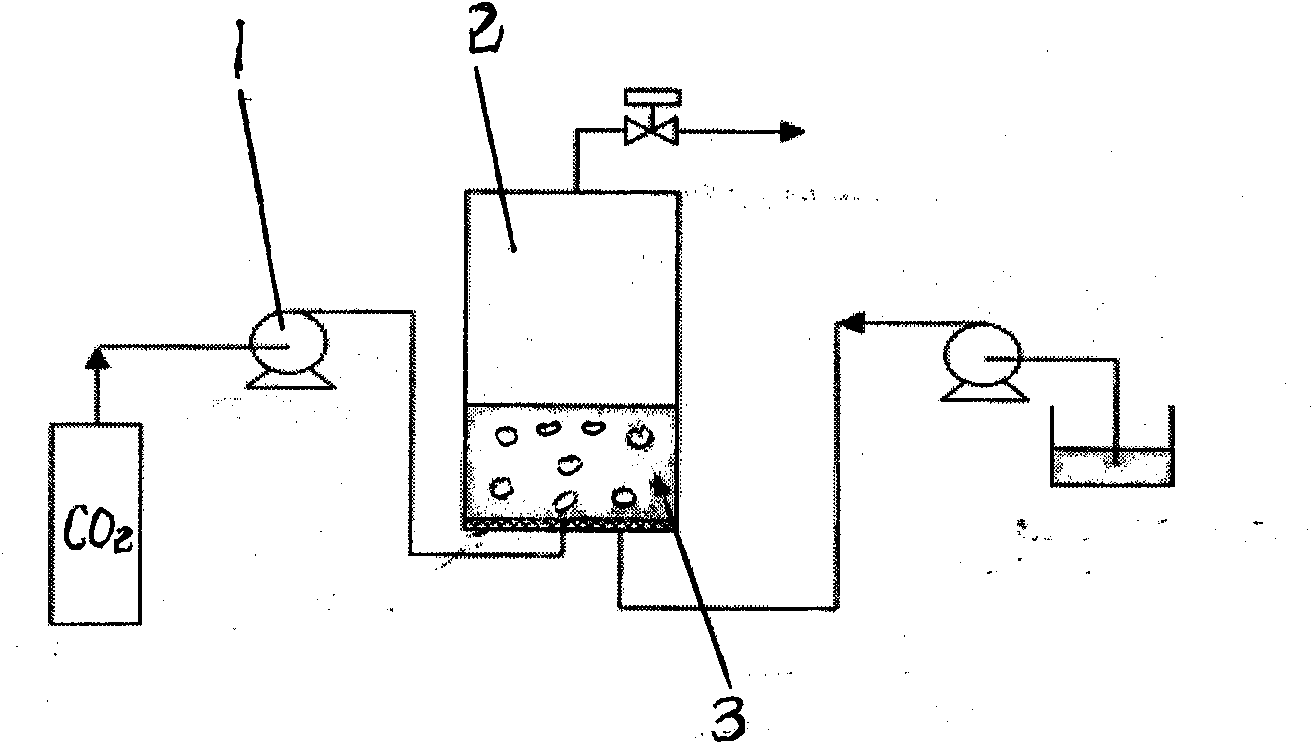

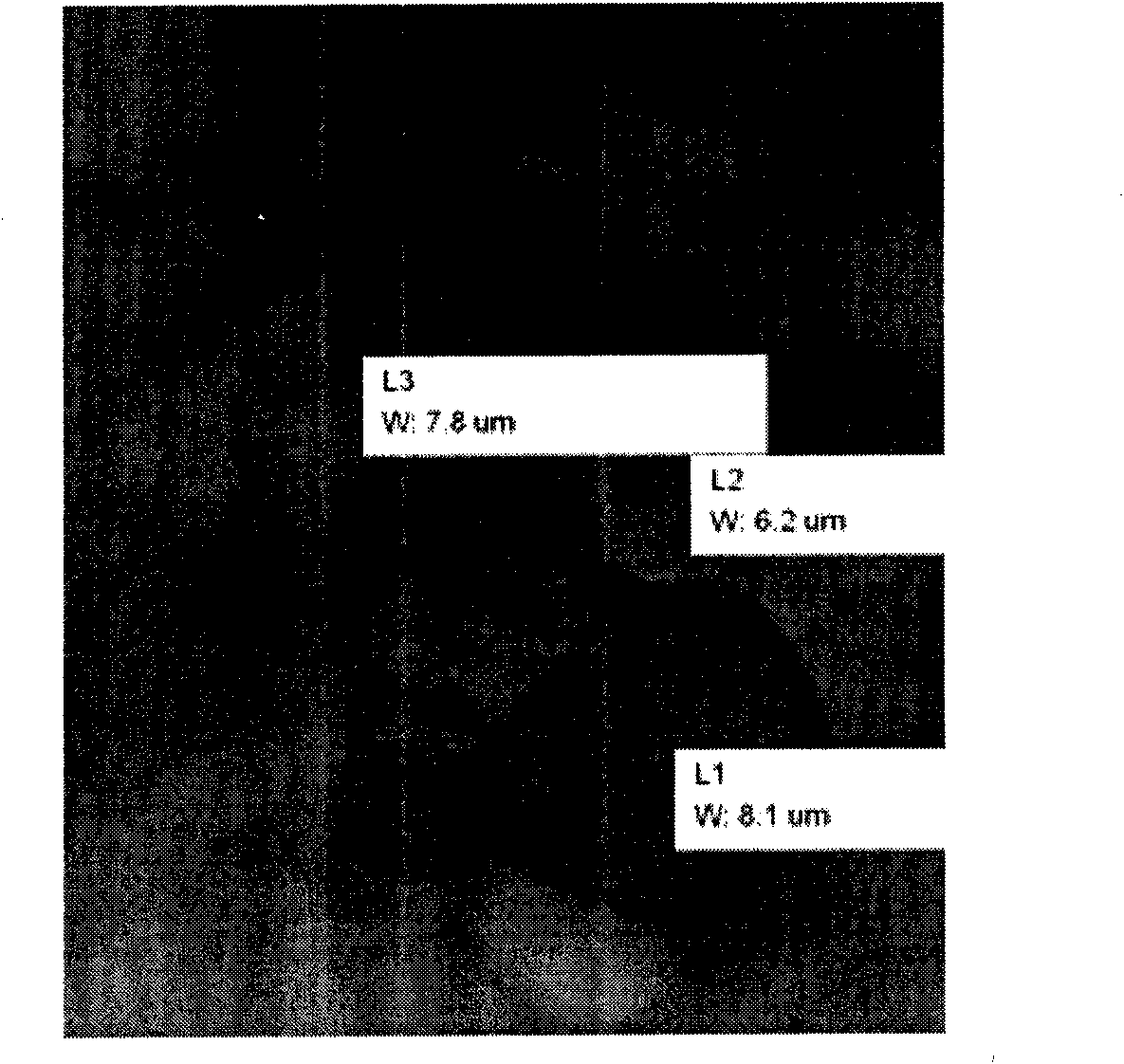

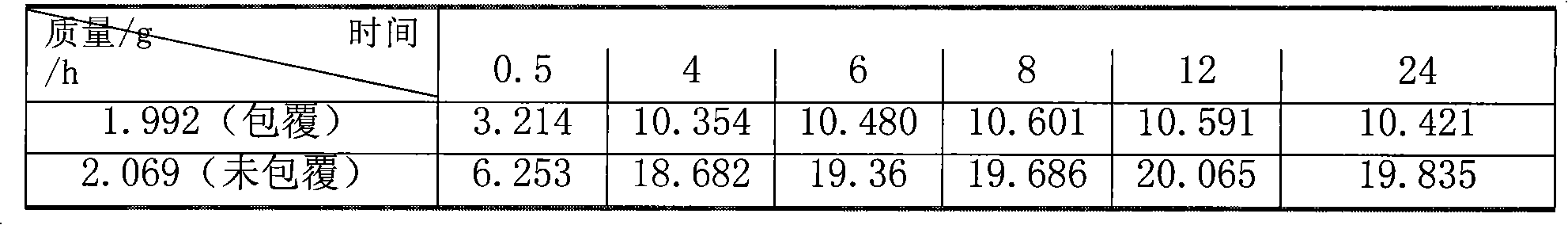

[0015] The coating process adopts a supercritical fluid anti-solvent process and utilizes a supercritical extraction device. The process is divided into: expansion of coating solution, extraction of solvent, deposition of coating on AN surface, solvent and CO 2 The separation of ammonium nitrate and the acetone nitrocellulose solution that grinds well and 10% mass fraction are made suspension (the mass ratio of ammonium nitrate and nitrocellulose is 99: 1), be placed in high-pressure deposition tank; Then pass into As an anti-solvent, carbon dioxide quickly dissolves with acetone, causing the solute nitrocellulose dissolved in it to produce a certain degree of supersaturation. After constant temperature and constant pressure extraction, the ...

Embodiment 2

[0017] Example 2, a supercritical fluid technology coating modification process for ammonium nitrate, mixing ammonium nitrate with acetone and grinding by mechanical grinding to make the particle size of ammonium nitrate 2-10 μm, and mixing the ground ammonium nitrate with 10% The acetone nitrocellulose solution is made into a suspension (the mass ratio of ammonium nitrate to nitrocellulose is 97:1), and placed in a high-pressure deposition kettle; then carbon dioxide is introduced as an anti-solvent, and it is rapidly miscible with acetone, causing the solute dissolved therein to be nitrated Cotton produces a certain degree of supersaturation, and the acetone is taken away by constant temperature and constant pressure extraction. The nitrocellulose is recrystallized and precipitated on the surface of ammonium nitrate particles, and finally particles with a particle size of 2-15 μm are obtained. The autoclave extraction temperature is 32 ° C, constant pressure The extraction pr...

Embodiment 3

[0018] Embodiment 3, a supercritical fluid technology coating modification process of ammonium nitrate, ammonium nitrate is mixed with acetone and ground by mechanical grinding method so that the particle size of ammonium nitrate is 2-10 μm, and the ground ammonium nitrate is mixed with 10% The acetone nitrocellulose solution is made into a suspension (the mass ratio of ammonium nitrate to nitrocellulose is 100:1), and placed in a high-pressure deposition kettle; then carbon dioxide is introduced as an anti-solvent, and it is rapidly miscible with acetone, causing the solute dissolved therein to be nitrated Cotton produces a certain degree of supersaturation, acetone is taken away by constant temperature and constant pressure extraction, nitrocellulose is recrystallized and precipitated on the surface of ammonium nitrate particles, and finally particles with a particle size of 2-15 μm are obtained. The autoclave extraction temperature is 30 ° C, constant pressure The extraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com