Bright white hot stamping foil as well as production method thereof

A production method and technology of hot stamping foil, applied in the field of printing and hot stamping, can solve the problems of strong application limitations, poor hot stamping effect, easy to scratch, etc., achieve wide applicability, good hot stamping effect, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

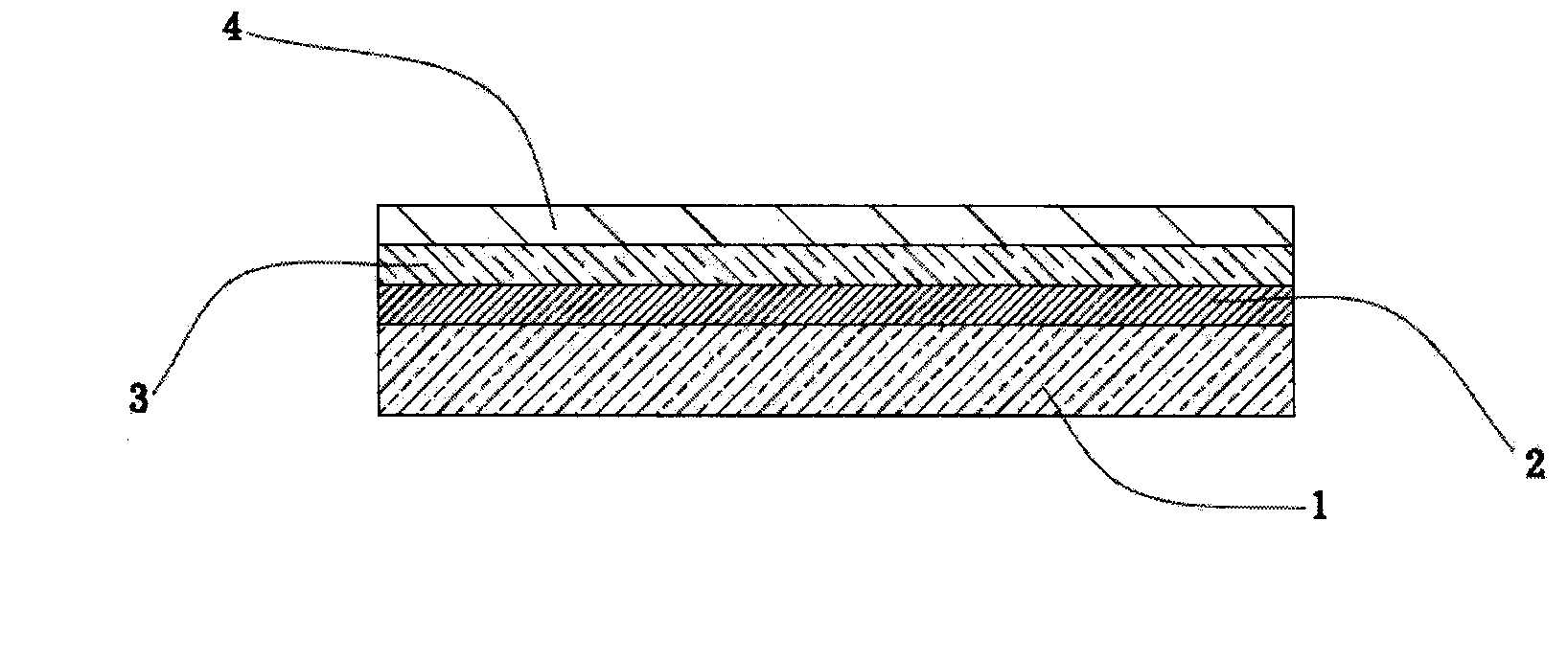

[0017] Such as figure 1 The bright white hot stamping foil shown in includes a biaxially oriented polyester film layer 1, and a release agent resin layer 2 is coated on one side of the biaxially oriented polyester film layer 1, and a release agent resin layer 2 is coated on the release agent resin layer 2. The outer surface of the colored layer 3 is coated with a colored layer 3, and the outer surface of the colored layer 3 is coated with a hot melt adhesive layer 4.

[0018] The colored layer 3 in the above is a pigment colored layer.

[0019] This embodiment also provides the production method of the above-mentioned bright white hot stamping foil, which includes two parts:

[0020] 1. Raw material preparation: (1) 2 parts by weight of high-gloss silicone resin, 10 parts by weight of acrylic resin, 1 part by weight of methyl silicone resin, 5 parts by weight of chopped fiber, 1 part by weight of two-component epoxy Resin, the cross-linking agent of 1 weight part, the stabil...

Embodiment 2

[0027] The structure of the bright white hot stamping foil provided in this example is consistent with Example 1, but the production method of the bright white hot stamping foil described in this example includes two parts:

[0028] 1. Preparation of raw materials: (1) 5 parts by weight of high-gloss silicone resin, 5 parts by weight of acrylic resin, 5 parts by weight of methyl silicone resin, 2 parts by weight of chopped fiber, 5 parts by weight of two-component epoxy Resin, the linking agent of 3 weight parts, the stabilizing agent of 5 weight parts, the methyl ethyl ketones of 60 weight parts and esters mixed solvent are made release agent resin through mixing, wetting and dispersing; (2) 10 weight parts of Acrylic resin, 15 parts by weight of epoxy acrylic resin, 1 part by weight of polystyrene, 5 parts by weight of polyamide, 3 parts by weight of trihydrocarbon methyl propane triacrylic resin, 30 parts by weight of titanium dioxide, 5 parts by weight of Castor oil, 80 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com