Preparation method of full-process industrialization globular calcium-based CO2 adsorbent

A calcium-based adsorbent and the technology of the adsorbent are applied in the field of preparation of the full-process industrialized spherical calcium-based CO2 adsorbent, which can solve the production methods that do not pay attention to the industrial scale of adsorbent pellets, are not suitable for industrial production preparation, and are precursors It can improve the CO2 adsorption capacity, improve the cycle stability, and reduce the capture cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

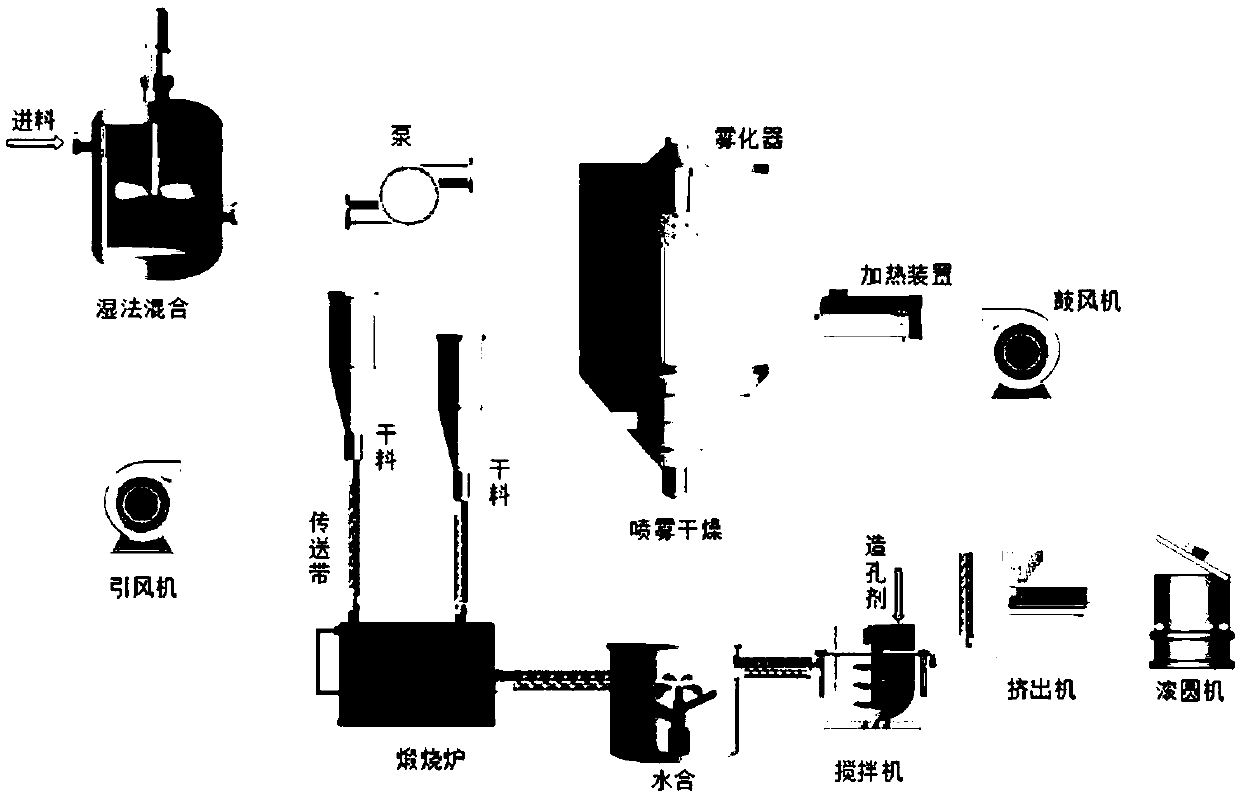

[0033] A full-process industrialized spherical calcium-based CO 2 The preparation method of adsorbent comprises the following steps:

[0034] (1) wet mixing the calcium-based adsorbent and the inert carrier precursor material to obtain a uniformly dispersed solution, wherein the wet mixing is used to make the two mixed more uniformly,

[0035] Taking the mass of the calcined powder as 1, the loading of the inert carrier is between 5% and 35%. During the calcination process, the calcium salt and the inert carrier precursor material will be dehydrated or other components to varying degrees, and finally become stable Oxide, so the proportion of each atom can be determined according to the proportion of the final oxide, the amount of calcium salt and inert carrier precursor added can be calculated from the mass loss in the calcination process, the amount of water added can be determined by the solubility of the precursor material, stirred and dissolved, at room temperature Or hea...

Embodiment 1

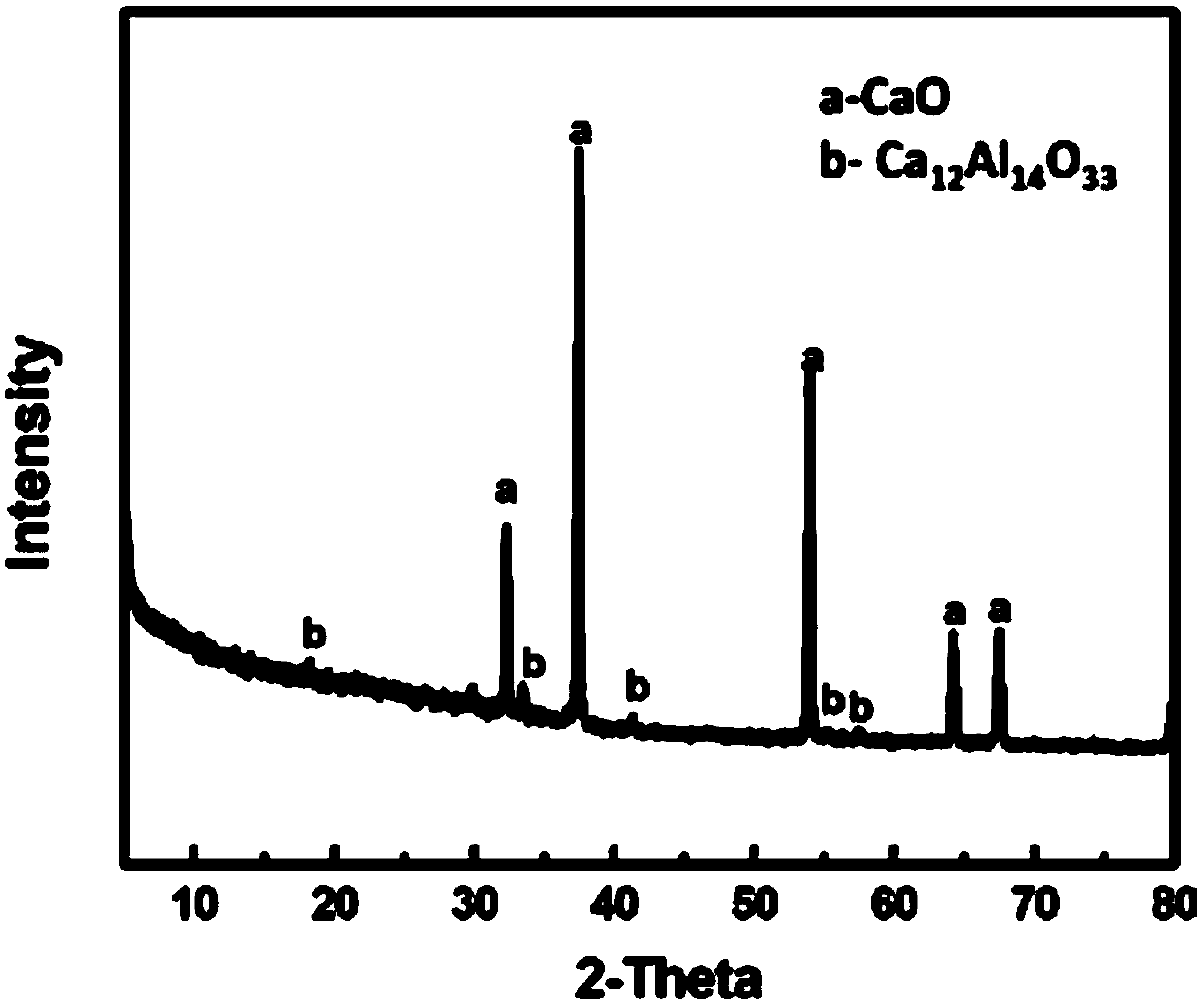

[0047] (1) Add 274.030g of calcium acetate monohydrate and 94.720g of aluminum nitrate nonahydrate into 1000mL of water, heat and stir in a 60°C water bath to form a completely clear precursor solution;

[0048] (2) Use a YC-015 spray dryer, set the air inlet temperature to 220°C, and pump the formed precursor solution into the drying chamber through a peristaltic pump at a rate of 1mL / min. After the spray drying is completed, the precursor solution is obtained in the collection tube. body powder;

[0049] (3) Calcinate the precursor powder in an air atmosphere at 900°C for 1 hour. After cooling, add 30ml of water to ensure that the calcium oxide component is completely reacted to form calcium hydroxide. After the calcium hydroxide wet material is dried, grind and sieve to below 200μm.

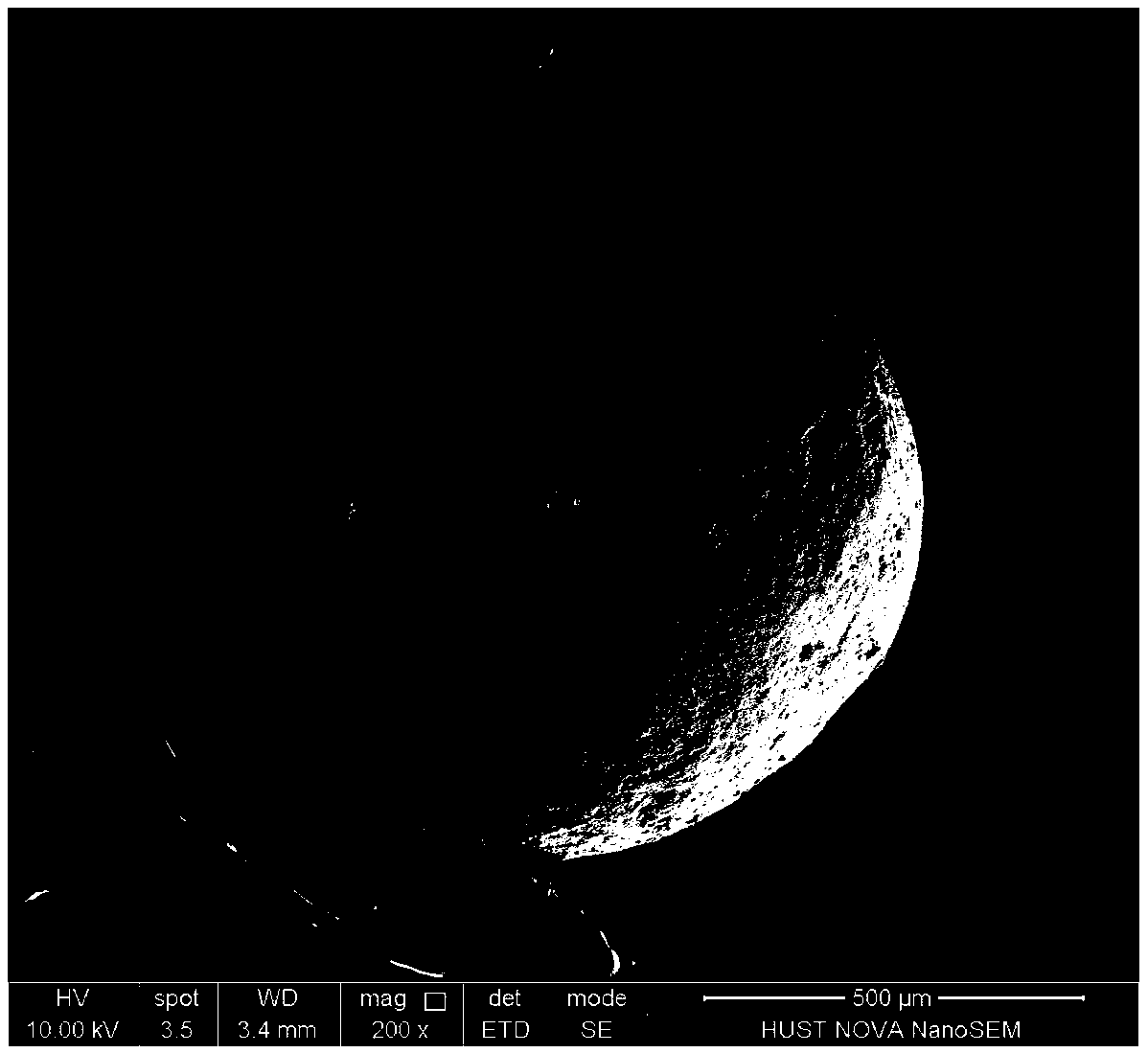

[0050] (4) Weigh 40 g of the calcium hydroxide powder obtained in step (3), add 10 mL of deionized water, and mix uniformly to obtain a wet material. Use the extrusion spheronizer of Shenzhe...

Embodiment 2

[0052] (1) Add 290.287g of calcium acetate monohydrate and 56.832g of aluminum nitrate nonahydrate into 1200mL of water, heat and stir in a 60°C water bath to form a completely clear precursor solution;

[0053] (2) Use a YC-015 spray dryer, set the air inlet temperature to 160°C, pump the formed precursor solution into the drying chamber through a peristaltic pump at a speed of 10mL / min, and obtain the precursor solution in the collection tube after the spray drying is completed. body powder;

[0054] (3) Calcinate the precursor powder in an air atmosphere at 950°C for 30 minutes. After it cools down, add 30ml of water to ensure that the calcium oxide component is completely reacted to form calcium hydroxide. After the calcium hydroxide wet material is dried, grind and sieve to below 200μm.

[0055] (4) Weigh 40 g of the calcium hydroxide powder obtained in step (3), add 10 mL of deionized water, and mix to obtain a wet material. Use the extrusion spheronizer of Shenzhen Xi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com