Tussah silk fiber or fabric cation modified finishing agent thereof and modified technique thereof

The technology of tussah silk and finishing agent is applied in the field of tussah silk and its silk fabric modification finishing agent and modification process, and can solve the problems of increasing environmental protection burden, decreasing dyeing uniformity of tussah silk and its silk fabrics, water consumption and The increase of sewage discharge and other problems can achieve the effect of improving the dyeing rate and color fixing rate, realizing the salt-free dyeing process and reducing the sewage discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

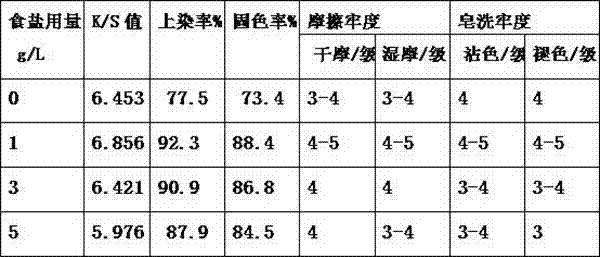

[0015] The quaternary ammonium salt is selected from lauryl trimethyl ammonium chloride, tetradecyl trimethyl ammonium chloride, hexadecyl trimethyl ammonium chloride or octadecyl trimethyl ammonium chloride solution At least one of them, based on the total amount of the modified finishing agent, has a concentration of 0.03 mol / L. The penetrating agent is fatty alcohol polyoxyethylene ether solution JFC, and its mass concentration is 1g / L based on the total amount of modified finishing agent. The pH value of the mixture was adjusted to a neutral range of 6-7. After the modified tussah silk fiber or its fabric treated with the modified finishing agent is dyed with reactive dyes, its dyeing rate, color fixation rate and color fastness are all obviously improved, and the dyeing effect is obviously improved. The amount of quaternary ammonium salt and penetrant used in this example is relatively low, and the cost of modification is relatively low.

Embodiment 2

[0017] The quaternary ammonium salt is selected from lauryl trimethyl ammonium chloride, tetradecyl trimethyl ammonium chloride, hexadecyl trimethyl ammonium chloride or octadecyl trimethyl ammonium chloride solution At least one of them has a concentration of 0.035 mol / L based on the total amount of the modified finishing agent. The penetrating agent is fatty alcohol polyoxyethylene ether solution JFC, and its mass concentration is 2g / L based on the total amount of modified finishing agent. This embodiment is the best modified finishing agent composition, which can make the reactive dye dyeing of the modified tussah silk fiber or its fabric obtain the best dyeing uptake rate, color fixation rate and color fastness.

Embodiment 3

[0019] The quaternary ammonium salt is selected from lauryl trimethyl ammonium chloride, tetradecyl trimethyl ammonium chloride, hexadecyl trimethyl ammonium chloride or octadecyl trimethyl ammonium chloride solution At least one of them, based on the total amount of the modified finishing agent, has a concentration of 0.04mol / L. The penetrating agent is fatty alcohol polyoxyethylene ether solution JFC, and its mass concentration is 5g / L based on the total amount of modified finishing agent. Compared with Example 1, the modification effect of this embodiment is slightly improved, but the improvement is not large. Because the amount of quaternary ammonium salt and penetrating agent is increased, the modification process can be shortened, that is, within the above-mentioned impregnation time range, use a short Time impregnation to achieve the modification effect.

[0020] The modified tussah silk fiber or its fabric obtained by the modified finishing agent and its modification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com