Processing method for improving quality of foods made of whole coarse cereal flour through extrusion modified coarse cereal powder

A processing method and a technology of miscellaneous grain powder, which are applied in the field of food processing, can solve the problems of not effectively improving the quality of noodles, reducing the elongation of buckwheat noodles, and destroying the nutritional value of highland barley powder, so as to improve quality and edible characteristics, reduce losses, Nutrient-rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

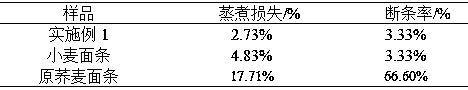

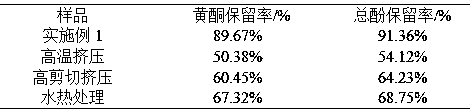

Examples

Embodiment 1

[0021] (1) The buckwheat raw material is crushed through a sieve hole of more than 40 meshes and then fed into a twin-screw extruder to prepare extrusion modified powder. Extrusion parameter setting: screw speed 25r / min; extruder sleeve temperature 50°C; water or steam is injected into the extruder to make the moisture content of the material 25%. After the extruder is started and stabilized, the above-mentioned samples are extruded and modified according to the set conditions, and the extruded samples are dried to reduce the moisture content of the samples to below 14%;

[0022] (2) Mixed powder: the ratio of original buckwheat flour and modified buckwheat flour is: every 250 g of original buckwheat flour is mixed with 5 g of modified buckwheat flour, and mixed evenly;

[0023] (3) Ultrafine treatment: The mixed powder is ultrafinely pulverized by a jet mill, and the D of the mixed powder particles is controlled. 50 at 100 μm;

[0024] (4) Molding: The mixed powder of step ...

Embodiment 2

[0026] (1) The raw materials of highland barley + oat + barley are crushed through a sieve of more than 40 meshes and fed into a twin-screw extruder to prepare extruded modified powder. Extrusion parameter settings: screw speed 75r / min, extruder sleeve temperature 100°C; water or steam is injected into the extruder to make the moisture content of the material 70%. After the extruder is started and stabilized, the above-mentioned samples are extruded and modified according to the set conditions, and the extruded samples are dried to reduce the moisture content of the samples to below 14%;

[0027] (2) Mixed powder: the ratio of the original mixed grain powder and the modified grain powder is: every 250 g of the original grain powder is mixed with 50 g of the modified grain powder, and mixed evenly;

[0028] (3) Ultrafine treatment: The mixed powder is ultrafinely pulverized by a jet mill, and the D of the mixed powder particles is controlled. 50 at 10 μm;

[0029] (4) Forming...

Embodiment 3

[0031] (1) The raw materials of sorghum + millet + potato + sweet potato are crushed through a sieve of more than 40 meshes and then fed into a twin-screw extruder to prepare extrusion modified powder. Extrusion parameter setting: screw speed 100r / min, extruder sleeve temperature 80°C; water or steam is injected into the extruder to make the moisture content of the material 50%. After the extruder is started and stabilized, the above-mentioned samples are extruded and modified according to the set conditions, and the extruded samples are dried to reduce the moisture content of the samples to below 14%;

[0032] (2) Mixed powder: the ratio of the original mixed grain powder to the modified grain powder is: every 250 g of the original grain powder is mixed with 20 g of the modified grain powder, and mixed evenly;

[0033] (3) Ultrafine treatment: The mixed powder is ultrafinely pulverized by a jet mill, and the D of the mixed powder particles is controlled. 50 at 50 μm;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com