Thermal treatment method for lead-free aluminum alloy

A heat treatment method and aluminum alloy technology, which is applied in the field of heat treatment of lead-free aluminum alloys, can solve the problems of no lead-free aluminum alloy production and heat treatment process disclosure, and achieve excellent corrosion resistance and weldability, excellent mechanical properties, and strong The effect of industrial operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

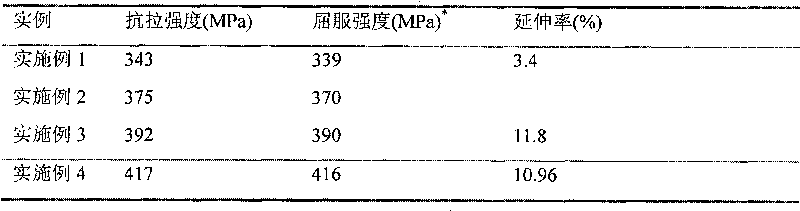

Examples

Embodiment 1

[0019] The extruded alloy is heat treated and then cold worked. The specific process flow is: heating up the heat treatment furnace to the set temperature (535±2°C)——furnace loading——solution treatment (heating 10°C / min—holding 60min)—quenching (quenching transfer time 5-10s)— - Aging treatment (to warm furnace, temperature rise 3 ℃ / min - heat preservation 10h) - out of the furnace air cooling.

Embodiment 2

[0021] The extruded alloy is heat treated and then cold worked. The specific process flow is: heating up the heat treatment furnace to the set temperature (535±2°C)——furnace loading——solution treatment (heating 10°C / min—holding 60min)—quenching (quenching transfer time 5-10s)— - Aging treatment (to warm furnace, temperature rise 3°C / min - heat preservation 10h) - Air cooling after leaving the furnace - Cold working (deformation amount 0.5%).

Embodiment 3

[0023] The extruded alloy is heat treated and then cold worked. The specific process flow is: heating up the heat treatment furnace to the set temperature (535±2°C)——furnace loading——solution treatment (heating 10°C / min—holding 60min)—quenching (quenching transfer time 5-10s)— - Aging treatment (to warm furnace, temperature rise 3 ℃ / min - heat preservation 10h) - out of the furnace air cooling - cold working (deformation 3.0%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com