Method for extracting alumina from coal ash through wet process

A technology for fly ash and alumina, applied in the removal of alumina/aluminum hydroxide, solid waste, etc., can solve the problems of low content of harmful impurities in residues, high alumina dissolution rate, corrosion of acid process equipment, etc. Energy consumption, simplified production process, reduced corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

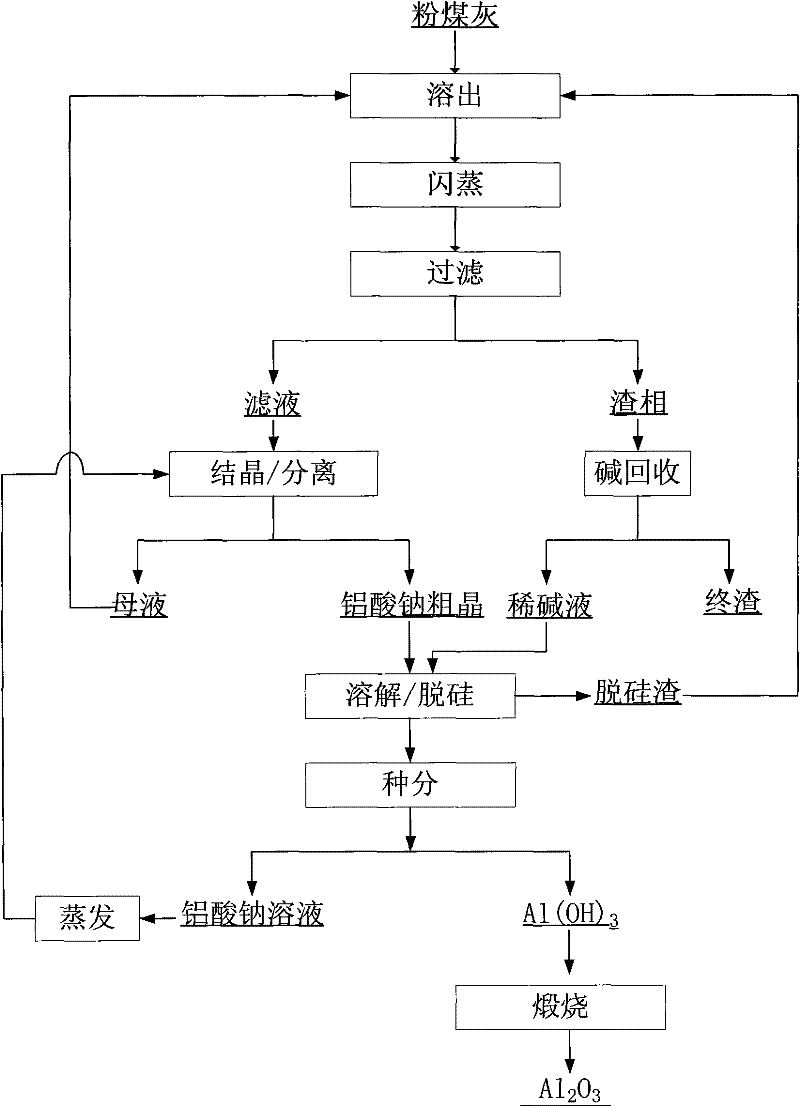

Image

Examples

Embodiment 1

[0025] The aluminum oxide in the fly ash is recovered by the low-temperature wet method provided by the present invention. Taking the fly ash in a certain place in Inner Mongolia as an example, the percentage content of the main element oxides of the fly ash is as follows:

[0026] al 2 o 3 SiO 2 Fe 2 o 3 CaO TiO 2 Na 2 O H 2 O burn reduction A / S

[0027] 41.41 39.54 2.40 3.67 1.38 0.21 6.1 2.81 1.05

[0028] Its recycling steps are:

[0029] The fly ash and the mass percentage are 50% NaOH solution mixed and placed in the reactor, the alkali solution and the fly ash mass ratio are 10.3: 1, the calcium oxide addition is 50% of the fly ash quality, and the temperature is raised to 260°C, reacted at 1.6MPa for 1 hour to obtain a mixed reaction product of alkali solution containing sodium aluminate and dealuminated slag. After the mixed reaction product was cooled to 100°C, it was filtered to obtain an alkali solution containing sodium aluminate and dealuminated sla...

Embodiment 2

[0033] The fly ash of embodiment 1 is mixed with the crystalline mother liquor in embodiment 1 and then placed in the reactor, the mass ratio of mother liquor and fly ash is 12.98: 1, and the calcium oxide addition is 35% of the fly ash quality, Raise the temperature to 300°C and react for 2 hours to obtain a mixed reaction product containing lye, sodium aluminate and dealuminated slag. After the mixed reaction product is cooled to 100°C, perform suction filtration to separate and obtain an alkali solution containing sodium aluminate and dealuminated slag. Slag, A / S=0.02 in the dealuminated slag at this time (A is the mass percentage of alumina, S is the mass percentage of silicon oxide), and the recovery rate of alumina in the fly ash is 98%.

[0034] Put the obtained sodium aluminate-containing alkali solution (filtered mother liquor) into a crystallization reactor, crystallize at 100°C for 10 hours with the addition of 8% seed crystals, and increase the caustic ratio of the ...

Embodiment 3

[0037] The fly ash of Example 1 is mixed with 30% NaOH solution by mass percentage and then placed in the reactor. The mass ratio of the alkali solution to the fly ash is 17.45:1, and the amount of calcium oxide added is 60% of the fly ash quality. %, heat up to 300°C, and react at 6.2MPa for 0.5h to obtain a mixed reaction product of lye containing sodium aluminate and dealuminated slag. After the mixed reaction product is cooled to 100°C, perform suction filtration to obtain aluminum-containing acid Sodium alkali solution and dealuminated slag, A / S=0.35 (A is the mass percentage of alumina, S is the mass percentage of silicon oxide) in the dealuminated slag at this time, the recovery rate of alumina in the fly ash is 66.67%.

[0038] Put the obtained sodium aluminate-containing alkali solution (filtered mother liquor) into a crystallization reactor, crystallize at 60°C for 3 hours with the addition of 5% seed crystals, and then increase the caustic ratio of the filtered cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com