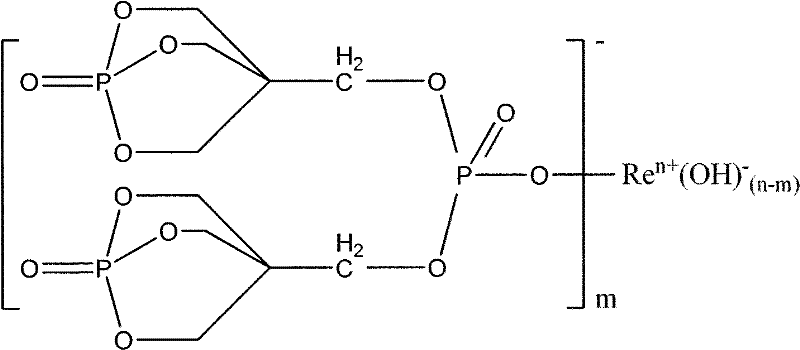

Phosphate rare earth salt with cagelike structure, synthesis method and application thereof

A technology of phosphate ester and rare earth salt, which is applied in the field of phosphate ester rare earth salt and its synthesis, and the preparation of flame retardants. It can solve the problems of small application amount and high price, and achieve broad application prospects, high phosphorus content, and wide synergy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

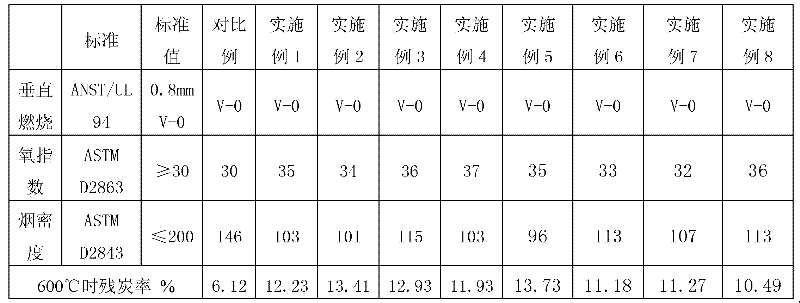

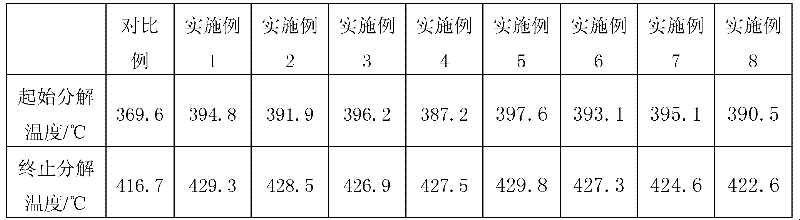

Examples

Embodiment 1

[0044] Embodiment 1, the chemical synthesis of phosphate rare earth salt-bis-PEPA phosphate lanthanum with cage structure

[0045] Synthesizing double PEPA phosphate lanthanum with cage structure with the method of the present invention, specifically comprises the following steps:

[0046] 1) Synthesis of intermediate bis-PEPA phosphoric acid chloride: 1-oxophospha-4-hydroxymethyl-2,6,7-trioxabis[2,2,2]octane (i.e. pentaerythritol phosphate, PEPA) 252g (1.4mol), phosphorus oxychloride 64ml (PEPA: phosphorus oxychloride molar ratio is 2: 1), dioxane 1062g (PEPA is 4.2 times of mass consumption), anhydrous magnesium chloride 3.5g (accounting for PEPA is added in the reactor with heating and agitating device according to the 1.4% of mass consumption), then slowly heats up, heats up to 105 ℃, heat preservation reaction 5 hours; 236.2 g of the intermediate bis-PEPA phosphoric acid chloride was obtained, with a yield of 80.5%.

[0047] 2) 220.3g (0.5mol) of the intermediate produc...

Embodiment 2

[0049] Embodiment 2, the chemical synthesis of phosphate rare earth salt-bis(bis-PEPA phosphate) lanthanum with cage structure

[0050] Synthesize two (two PEPA phosphate) lanthanums with cage structure with the method of the present invention, specifically comprise the following steps:

[0051] 1) Synthesis of intermediate bis-PEPA phosphoric acid chloride: 1-oxophospha-4-hydroxymethyl-2,6,7-trioxabis[2,2,2]octane (i.e. pentaerythritol phosphate, PEPA) 528g (2.93mol), phosphorus oxychloride 128ml (PEPA: phosphorus oxychloride molar ratio is 2.1: 1), acetonitrile 1416g (PEPA is 2.68 times of mass consumption), anhydrous aluminum chloride 14.16g (accounts for PEPA 2.68% of the mass dosage) was added into a reactor with a heating and stirring device, then the temperature was raised slowly to 82° C., and the heat preservation reaction was carried out for 6 hours; The intermediate product bis-PEPA phosphoric acid chloride was 520.4g, and the yield was 88.6%.

[0052] 2) 440.6g o...

Embodiment 3

[0054] Embodiment 3, the chemical synthesis of phosphate rare earth salt-bis-PEPA phosphate cerium with cage structure

[0055] The double PEPA phosphate cerium with cage structure is synthesized with the method of the present invention, specifically comprises the following steps:

[0056] 1) Synthesis of intermediate product bis-PEPA phosphoric acid chloride: same as Example 1.

[0057] 2) 220.3 g of the intermediate product bis-PEPA phosphoric acid chloride, 141.0 g of cerium chloride (bis-PEPA phosphoric acid chloride: cerium chloride molar ratio is 1: 1) and 1000 ml of water (4.54 times of the intermediate product by mass consumption) ) into a reactor with a heating and stirring device, the temperature was raised to 90° C., and the insulation reaction was carried out for 1 hour; after the reaction, the temperature was lowered and cooled, and after filtration, washing and drying, 242.4 g of the final product bis-PEPA phosphate cerium was obtained. Yield 81.3%.

[0058] Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com