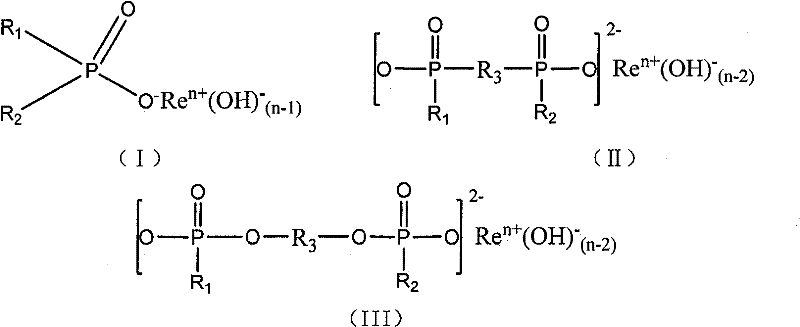

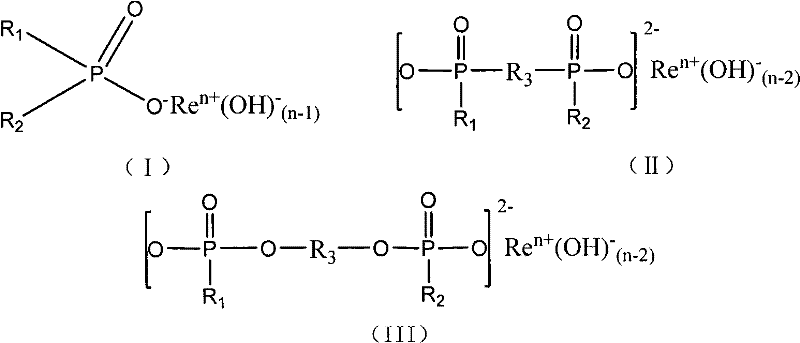

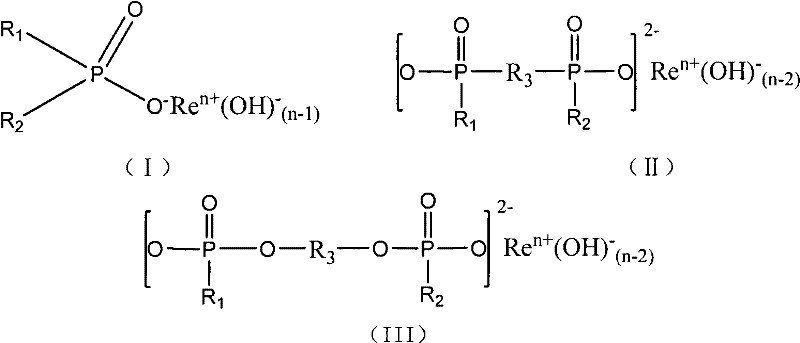

Rear earth organic phosphonate flame retardant, synthesizing method and use thereof

A technology of rare earth organic phosphate and organic phosphonic acid, which is applied in the fields of fine chemicals and polymer materials, and achieves the effects of high phosphorus content, effective and feasible process, and wide synergy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1. Synthesis of Lanthanum Dimethylphosphonate

[0065] Add 94g of dimethylphosphonic acid and 500ml of ethanol aqueous solution with a concentration of 15% into the reactor. The structural formula of dimethylphosphonic acid is as shown in general formula (IV), R 1 , R 2 For methyl. Under stirring, a 20% sodium hydroxide aqueous solution containing 44 g of sodium hydroxide was added and reacted at 70° C. for 2 hours. Then, a 20% lanthanum chloride aqueous solution containing 245.5 g of lanthanum chloride was added, and then the pH value of the solution was adjusted to 7-8 with sodium hydroxide solution, and the solution was stirred at 20-30°C for 2 hours. After the reaction, it was filtered, dried and crushed to obtain 244.2 g of lanthanum bismethylphosphonate with a yield of 91.8%.

Embodiment 2

[0066] Example 2. Synthesis of Gadolinium Di-tert-butylphosphonate

[0067] Add 178g of bis-tert-butylphosphonic acid and 1000ml of ethanol aqueous solution with a concentration of 15% into the reactor. The structural formula of bis-tert-butylphosphonic acid is shown in general formula (IV), R 1 , R 2 It is tert-butyl. Under stirring, a 20% sodium hydroxide aqueous solution containing 44 g of sodium hydroxide was added and reacted at 60°C for 2 hours. Then a 20% gadolinium chloride aqueous solution containing 263.75 g of gadolinium chloride was added, and the pH value of the solution was adjusted to 7-8 with sodium hydroxide solution, and the solution was stirred at 60° C. for 2 hours. After the reaction is completed, it is filtered, dried and pulverized to obtain 332.2 g of gadolinium bis-tert-butylphosphonate with a yield of 90.2%.

Embodiment 3

[0068] Example 3. Synthesis of bisethoxy lanthanum phosphate

[0069] Add 154g of bisethoxy phosphoric acid and 800ml of isopropanol solution with a concentration of 15% in the reactor. The structural formula is as shown in general formula (IV), R 1 , R 2 It is ethoxy. Under stirring, a 20% sodium hydroxide aqueous solution containing 44 g of sodium hydroxide was added and reacted at 60° C. for 1 hour. Then, a 15% lanthanum chloride aqueous solution containing 245.5 g of lanthanum chloride was added, and then the pH value of the solution was adjusted to 7-8 with sodium hydroxide solution, and the solution was stirred at 60°C for 2 hours. After the reaction, it is filtered, dried and crushed to obtain 297.3 g of bisethoxy lanthanum phosphate with a yield of 91.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com