Organic phosphate rare earth salt nucleater, synthesis method and application thereof

An organic phosphate ester and a synthesis method technology, applied in the fields of fine chemicals and polymer materials, can solve the problems of high melting point and insignificant anti-reflection effect, and achieve the effects of wide practicability, effective and feasible process, and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

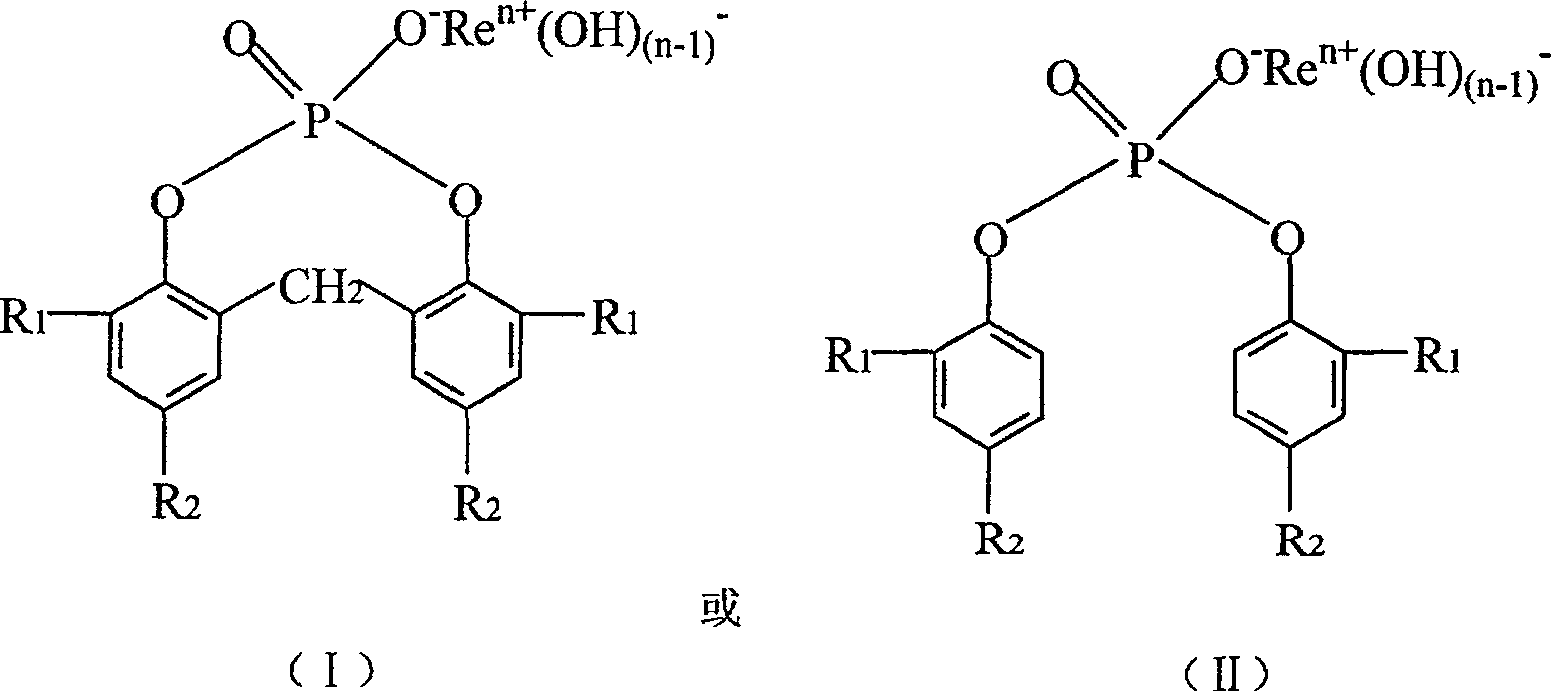

Image

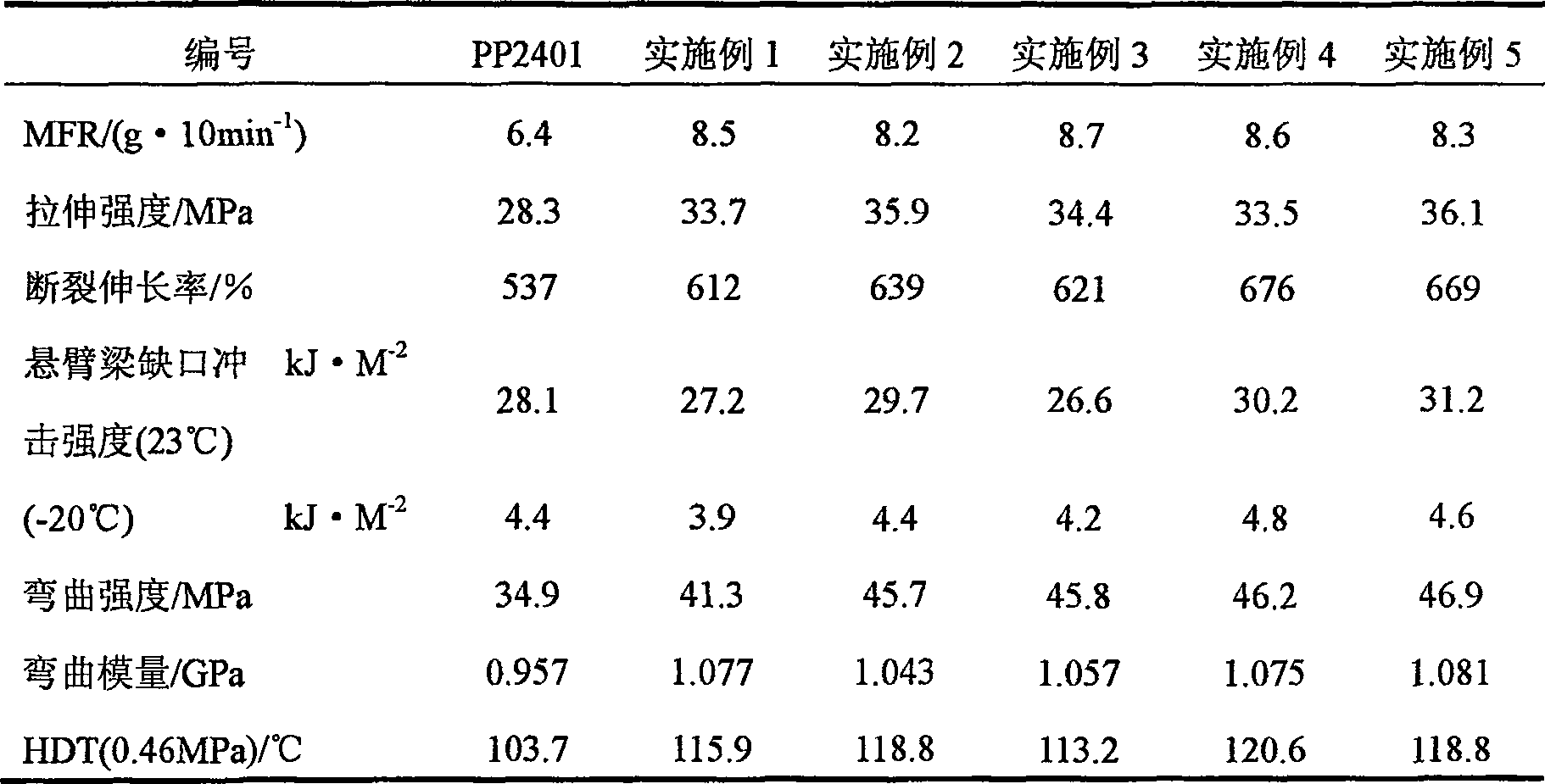

Examples

Embodiment 1

[0040] Embodiment 1: the synthesis of two (2,4-dimethylphenoxy) lanthanum phosphates

[0041] Add the ethanol solution that contains 306g two (2,4-dimethylphenoxy) phosphoric acid in reactor, its structural formula is as shown in general formula (IV), R 1 , R 2 For methyl. Under stirring, 20% sodium hydroxide aqueous solution containing 64 g of sodium hydroxide was added, and it was made to react at 80 degreeC for 2 hours. Then, a 20% aqueous solution of lanthanum chloride containing 343.7 g of lanthanum chloride was added, followed by stirring at normal temperature for 2 hours. After the reaction, filter, dry, and pulverize to obtain 440.3 g of bis(2,4-dimethylphenoxy)lanthanum phosphate.

Embodiment 2

[0042] Embodiment 2: the synthesis of 2,2'-methylene-bis(4,6-dimethylphenoxy)lanthanum phosphate

[0043] In reactor, add the ethanol solution that contains 318g2,2'-methylene-bis(4,6-dimethylphenoxy)phosphoric acid, its structural formula is as shown in general formula (III), R 1 , R 2 For methyl. Under stirring, 20% sodium hydroxide aqueous solution containing 64 g of sodium hydroxide was added, and it was made to react at 100 degreeC for 1 hour. Then, a 15% aqueous solution of lanthanum chloride containing 368.25 g of lanthanum chloride was added, followed by stirring at 80° C. for 1 hour. After completion of the reaction, filter, dry, and pulverize to obtain 447.93 g of 2,2'-methylene-bis(4,6-dimethylphenoxy)lanthanum phosphate.

Embodiment 3

[0044] Embodiment 3: two (2, the synthesis of 4-di-tert-butylphenoxy) cerium phosphate

[0045] Add the methanol solution that contains 474g two (2,4-di-tert-butylphenoxy) phosphoric acid in the reactor, its structural formula is as shown in general formula (IV), R 1 , R 2 For tert-butyl. Under stirring, 20% sodium hydroxide aqueous solution containing 56 g of sodium hydroxide was added, and it reacted at 80 degreeC for 2 hours. Then, 20% cerium chloride aqueous solution containing 394.8g of cerium chloride was added, and it stirred at normal temperature for 2 hours. After the reaction, filter, dry, and pulverize to obtain 620.78 g of bis(2,4-di-tert-butylphenoxy)cerium phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com