Feed additive using clay as carrier and preparation method thereof

A technology of feed additive and clay, which is applied in the field of feed additive with clay as the carrier and its preparation, can solve the problems of single mycotoxin and low efficiency, and achieve the effects of reducing morbidity, high production efficiency and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

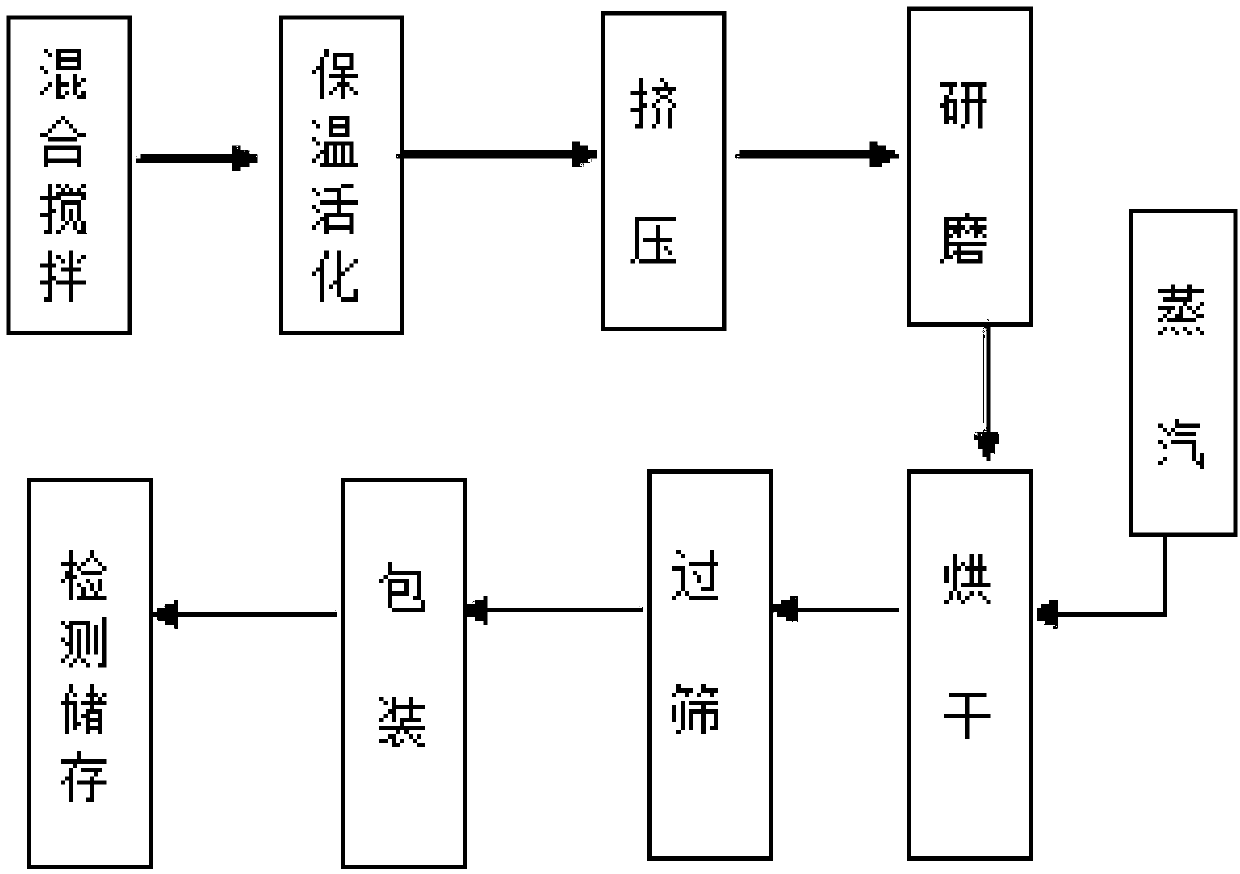

[0025] like figure 1 As shown, it is a preparation method of a feed additive with clay as a carrier according to the present invention, which includes the following steps: adding clay and sodium salt solution in a formula amount to the mixer, starting the mixer to mix the materials evenly; Add the vegetable fatty acid ester and activator into the mixer for organic activation, keep warm, stir evenly and then extrude; grind the extruded particles to make solid powder; dry the material at 80-100°C The sieve screen above the mesh is obtained. Wherein, the sodium salt solution is prepared from sodium salt and deionized water in a ratio of 1:2-5.

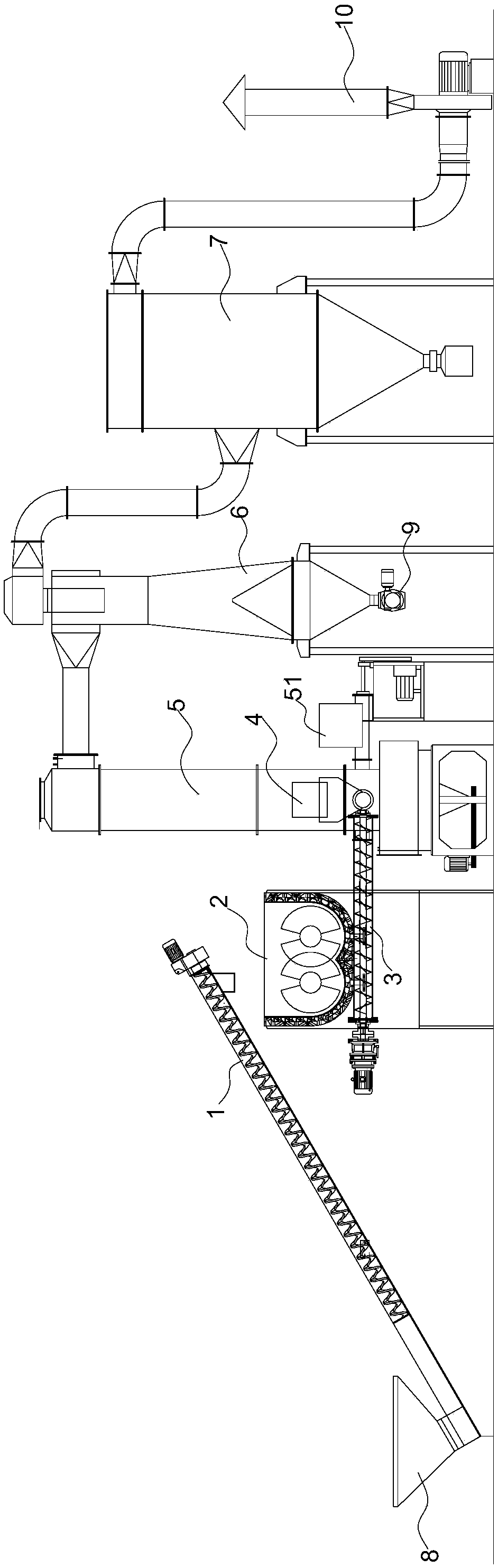

[0026] like figure 2 As shown, it is a production system of a feed additive with clay as a carrier according to the present invention, which includes a screw feeder 1, a mixer 2, a twin-screw extruder 3, a grinder 4, and an air conveying dryer 5 , Screening machine 6 and dust collector 7.

[0027] The screw feeder 1 is installed obli...

Embodiment 1

[0031] A feed additive with clay as carrier, which comprises the following components in terms of mass percentage: 40% of clay; 40% of vegetable fatty acid ester; 10% of sodium salt; 10% of activator.

[0032] The preparation method of above-mentioned feed additive is as follows:

[0033] Mix the sodium salt of formula quantity with deionized water according to the ratio of 1:2, be mixed with sodium salt solution; Add the clay of formula quantity and prepared sodium salt solution in mixer 2, start mixer 2 to make The materials are mixed evenly; the vegetable fatty acid ester and the activator are added to the mixer 2 for organic activation, kept warm, stirred evenly and then extruded; the extruded particles are ground to make a solid powder; the materials are dried at 80°C, Sieve with a sieve of more than 200 meshes.

Embodiment 2

[0035]A feed additive with clay as the carrier, which comprises the following components in terms of mass percentage: 65% of clay; 30% of vegetable fatty acid ester; 3% of sodium salt; 2% of activator.

[0036] The preparation method of above-mentioned feed additive is as follows:

[0037] Mix the formulated amount of sodium salt with deionized water at a ratio of 1:3.5 to prepare a sodium salt solution; add the formulated amount of clay and the prepared sodium salt solution to the mixer 2, and start the mixer 2 to The materials are mixed evenly; the vegetable fatty acid ester and the activator are added to the mixer 2 for organic activation, kept warm, stirred evenly and then extruded; the extruded particles are ground to make a solid powder; the materials are dried at 90°C, Sieve with a sieve of more than 200 meshes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com