Selective extraction recycling method of waste ternary lithium battery

A ternary lithium battery and recycling method technology, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve problems such as poor industrial operability and lengthy process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

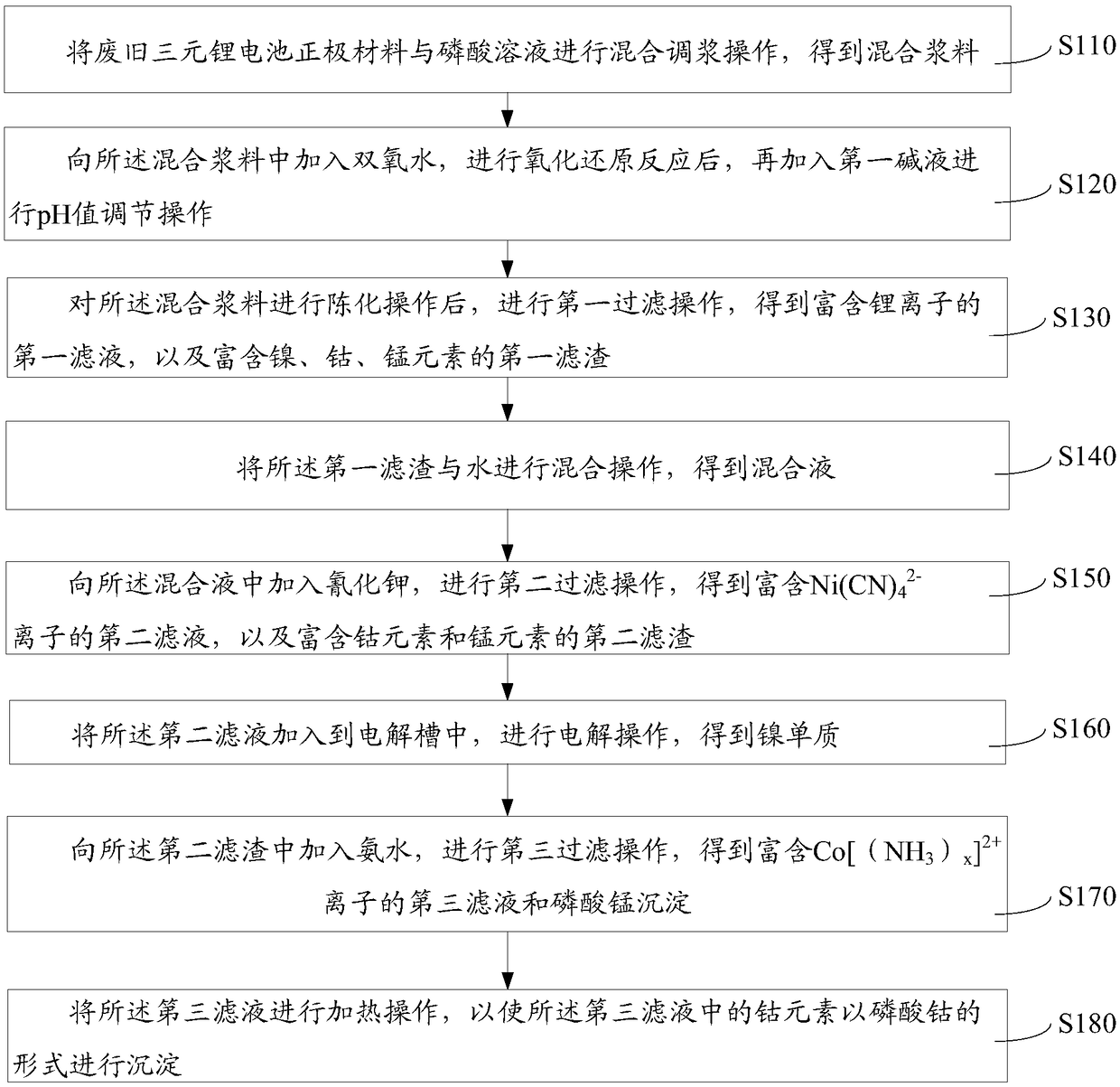

Method used

Image

Examples

Embodiment 1

[0073] Mix 1 kg of waste ternary lithium battery cathode material with 5 kg of phosphoric acid solution with a concentration of 1 mol / L for slurry preparation, raise the temperature of the reaction system to 60°C, and continue stirring at a speed of 50 r / min for 20 minutes to obtain a mixed slurry;

[0074] Add 5 mol of hydrogen peroxide to the mixed slurry at a constant speed, and continue to add the hydrogen peroxide for 1 hour. After the oxidation-reduction reaction, add a sodium hydroxide solution with a mass concentration of 40wt.% to adjust the pH value to adjust the mixed slurry. pH value of the feed to 3.0;

[0075] After performing the aging operation on the mixed slurry for 0.5h, the first filtering operation is carried out by adopting the intermittent pressurization and decompression filtering operation method to obtain the first filtrate rich in lithium ions, and the first filtrate rich in nickel, cobalt, and manganese. The first filter residue of the element, and ...

Embodiment 2

[0082] Mix 1 kg of waste ternary lithium battery cathode material with 10 kg of phosphoric acid solution with a concentration of 2 mol / L for slurry preparation, raise the temperature of the reaction system to 70°C, and continue stirring at a speed of 40 r / min for 25 minutes to obtain a mixed slurry;

[0083] Add 10 mol of hydrogen peroxide to the mixed slurry at a constant speed, and continue to add the hydrogen peroxide for 2 hours. After the oxidation-reduction reaction, add a sodium hydroxide solution with a mass concentration of 30wt.% to adjust the pH value to adjust the mixed slurry. pH value of the material to 3.5;

[0084] After performing the aging operation on the mixed slurry for 0.5h, the first filtering operation is carried out by adopting the intermittent pressurization and decompression filtering operation method to obtain the first filtrate rich in lithium ions, and the first filtrate rich in nickel, cobalt, and manganese. The first filter residue of the elemen...

Embodiment 3

[0091] Mix 1 kg of waste ternary lithium battery positive electrode material with 15 kg of phosphoric acid solution with a concentration of 3.5 mol / L for slurry preparation, raise the temperature of the reaction system to 75°C, and continue stirring at a speed of 48 r / min for 23 minutes to obtain a mixed slurry ;

[0092] Add 12 mol of hydrogen peroxide to the mixed slurry at a constant speed, and continue to add the hydrogen peroxide for 5 hours. After the oxidation-reduction reaction, add a sodium hydroxide solution with a mass concentration of 35wt.% to adjust the pH value to adjust the mixed slurry. pH value of the material to 3.8;

[0093]After performing the aging operation on the mixed slurry for 1.5 hours, the first filtering operation was performed by adopting the intermittent pressurization and decompression filtering operation method to obtain the first filtrate rich in lithium ions, and the first filtrate rich in nickel, cobalt, and manganese. The first filter res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com