Full-body porcelain tile and preparing method thereof

A ceramic tile, whole body technology, applied in the direction of manufacturing tools, ceramic molding machines, molding conveyors, etc., can solve the problems of unreasonable material combination and distribution of colors, complicated processes, and high product costs, and achieve strong industrial operability, Simple process flow and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

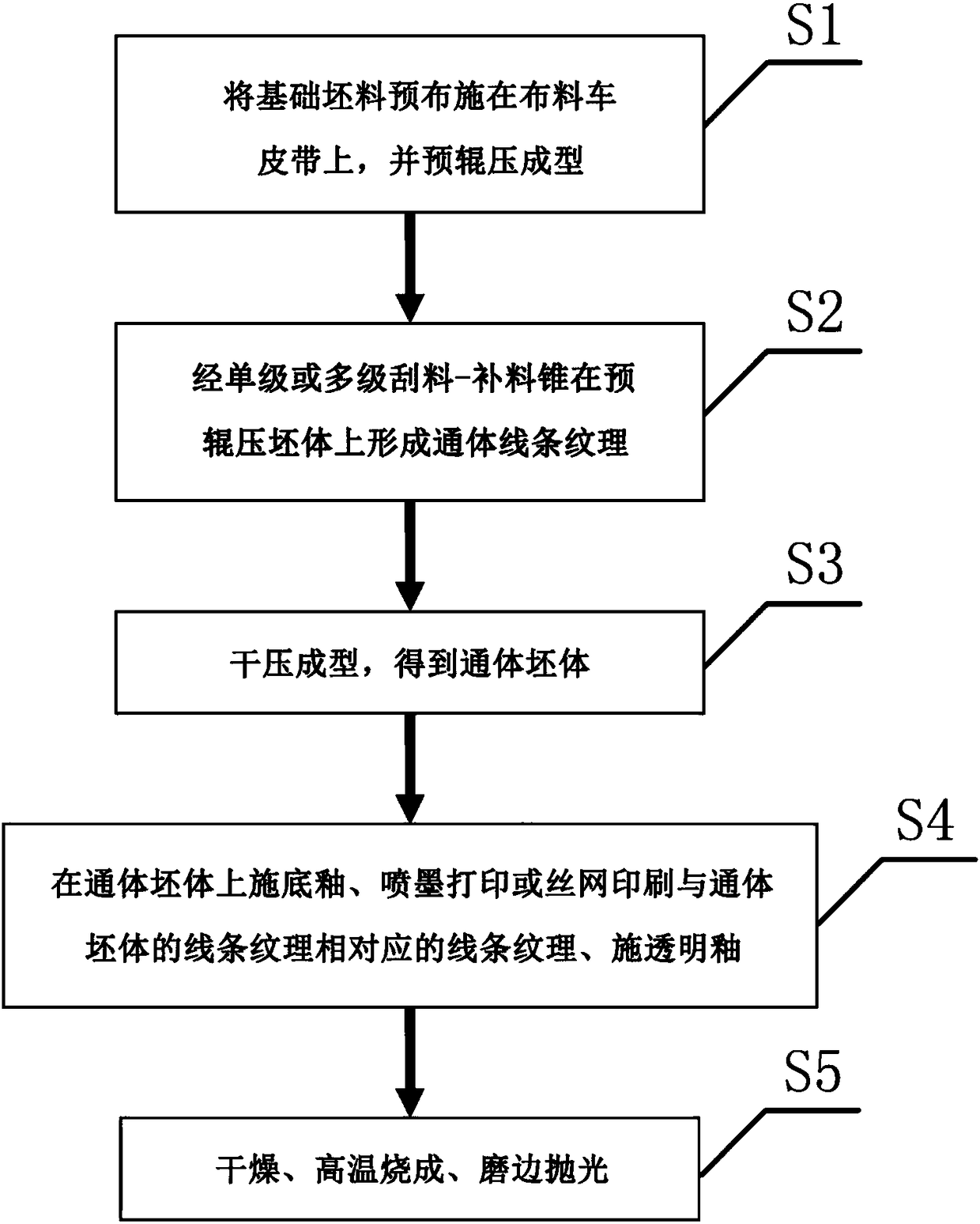

[0035] like figure 1 Shown, a kind of preparation method of whole body porcelain tile, comprises the steps:

[0036] S1: In terms of mass fraction, the basic material of the ceramic body is made of quartz, kaolin, feldspar and ball clay according to the chemical composition: SiO 2 69.5%, Al 2 o 3 19.5%, K 2 O 5.6%, Na 2 O 3.8%, CaO 1.2%, MgO 0.4% ingredients, prepared by wet ball milling and spray drying;

[0037] Add black ceramic pigment (accounting for 1.5wt% of the mass fraction of the basic ceramic body base material) to the obtained part of the ceramic body base material, and dry mix to obtain a color-matched ceramic powder (blue). Distribute the basic blank of the ceramic body on the belt of the distribution car, and pre-roll forming, and control the forming pressure to obtain a bulk density of 0.8g / cm 3 , a green body with a thickness of 10mm;

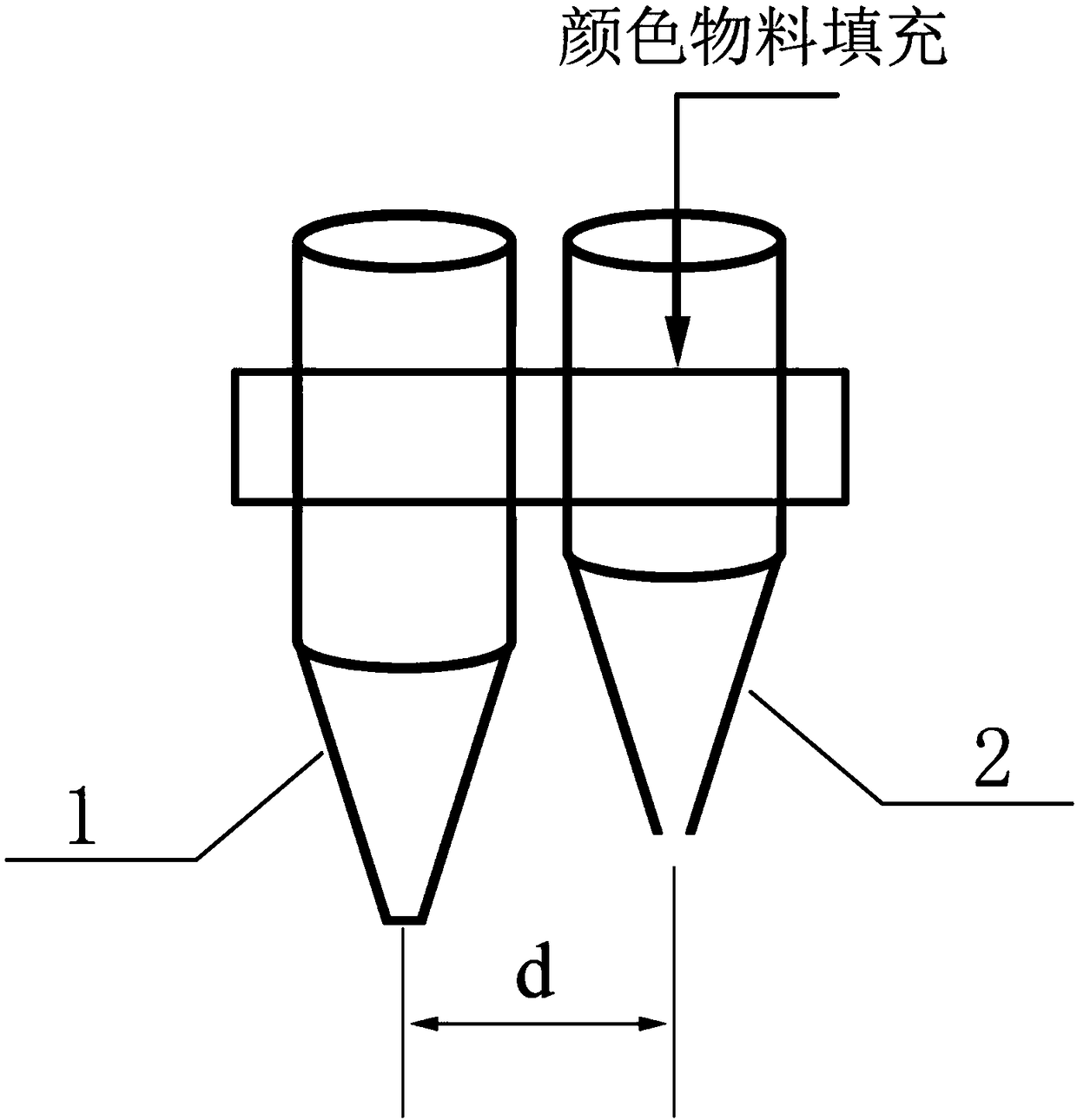

[0038] S2: Utilize the green body with good color figure 2 The scraper cone-feeder cone structure shown forms the ...

Embodiment 2

[0046] like figure 1 Shown, a kind of preparation method of whole body porcelain tile, comprises the steps:

[0047] In terms of mass fraction, the base material of the ceramic body is made of quartz, kaolin, feldspar and talc according to the chemical composition: SiO 2 72%, Al 2 o 3 22%, K 2 O 1.8%, Na 2 O 2.2%, CaO 0.9%, MgO 1.1% ingredients, prepared by wet ball milling and spray drying;

[0048] Add 8wt% (the mass fraction of the vanadium-zirconium blue material to the basic material of the ceramic body) of the vanadium-zirconium blue material to the obtained part of the ceramic body base material and dry mix to obtain a color-matched ceramic powder (light blue) .

[0049] Put the basic powder of the ceramic green body on the belt of the distribution car, and after pre-rolling, the bulk density is 1.3g / cm 3 , a green body with a thickness of 15mm;

[0050] Utilize the green body with good color figure 2 The scraper cone-feeder cone structure shown forms a whole...

Embodiment 3

[0053] like figure 1 Shown, a kind of preparation method of whole body porcelain tile, comprises the steps:

[0054] In terms of mass fraction, the base material of the ceramic body is made of quartz, feldspar, talc and ball clay according to the chemical composition: SiO 2 66%, Al 2 o 3 19%, K 2 O 6.0%, Na 2 O 5.4%, CaO 1.8%, MgO 1.8% ingredients, prepared by wet ball milling and spray drying;

[0055] Add 1wt% (wrapped yellow material accounts for the mass fraction of the ceramic body base material) of the packaged yellow material and 3wt% (the mass fraction of the zirconium-praseodymium yellow material accounts for the ceramic body base material) of zirconium to the obtained part of the ceramic body base material. The praseodymium yellow material is dry-mixed to obtain a color-matched ceramic powder (light yellow).

[0056] Put the basic powder of the ceramic body on the belt of the distribution car, and after pre-rolling, the bulk density is 1.5g / cm 3 , a green bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com