Pull-apart bread as well as production process and production line of pull-apart bread

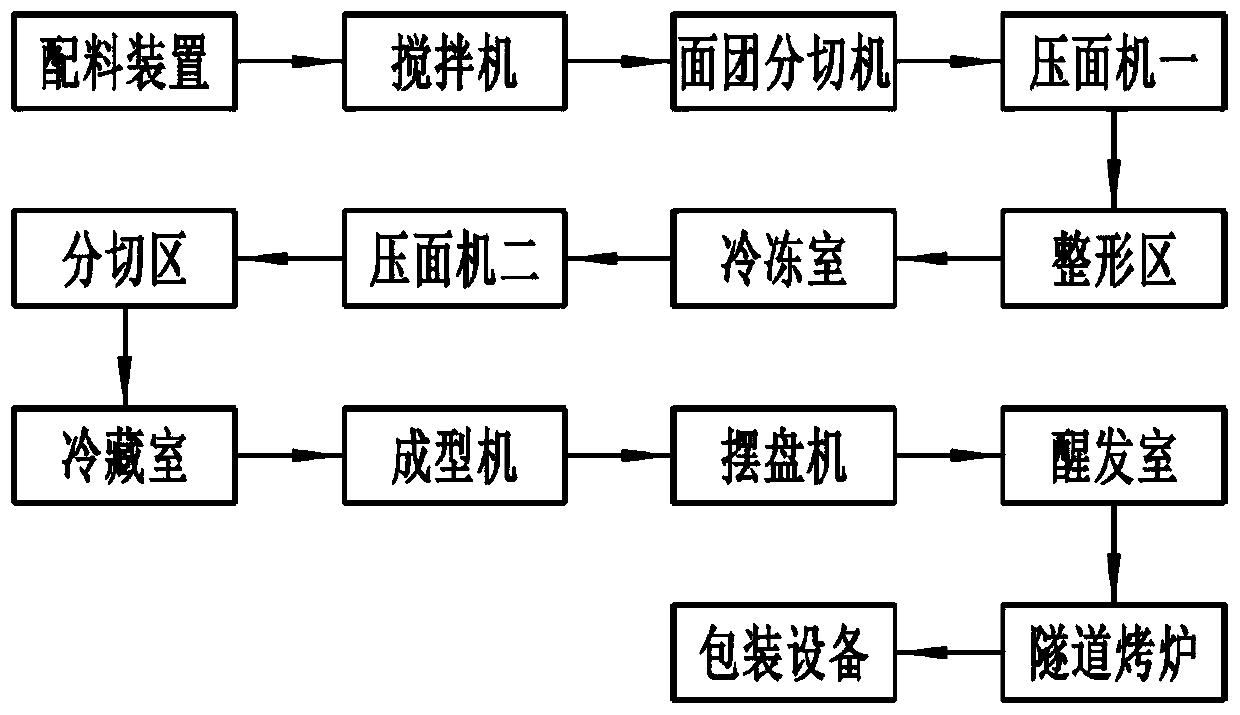

A production process and production line technology, applied in the field of hand-torn bread production process and production line, can solve problems such as poor anti-aging effect of hand-torn bread, achieve the advantages of large-scale commercial promotion, good anti-aging effect, and improve the effect of fluffy taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Shredded bread, produced by:

[0040] (1) Ingredients: Mix 22kg of water, 0.8kg of compound enzyme preparation, 1.2kg of excipients, 0.08kg of calcium propionate, and 0.015kg of sodium dehydroacetate to obtain small ingredient water. Add 0.5kg of sorbitol, 1kg of glycerin, milk Mix 0.3 kg of soy sauce essence and 2.5 kg of egg white to obtain material A; mix 6 kg of ghee, 0.4 kg of emulsifier, and 2.0 kg of custard sauce to obtain material B; the auxiliary materials include modified starch, fresh milk powder, salt, and glucose Acid-δ-lactone; the ingredients of the compound enzyme preparation include: edible corn starch, flour, food additives; food additives include: xylan, hemicellulase, calcium sulfate, glucose oxidase, vitamin C, fat Enzymes, amylases;

[0041] (2) Dough making: add 45kg of flour, 9kg of powdered sugar, 0.5kg of whole milk powder, and 1.5kg of dry yeast into the blender, stir at a slow speed for 2 minutes, and then add small ingredients water, 1.4kg...

Embodiment 2

[0049] Shredded bread, prepared by:

[0050] (1) Ingredients: Weigh the raw materials of shredded bread: 38kg flour, 5kg powdered sugar, 0.9kg whole milk powder, 1.5kg fructose syrup, 2kg dry yeast, 8kg sweet slice oil, 20.08kg water, 5.9kg ingredient A Mixture B 5.0kg; raw materials of small ingredient water include: water 18kg, compound enzyme preparation 0.5kg, auxiliary materials 1.5kg, calcium propionate 0.06kg, sodium dehydroacetate 0.020kg; raw materials of ingredient A include: sorbitol 0.6 kg, glycerin 0.6kg, milk sauce essence 0.2kg, egg white 4.5kg; the raw materials of material B include: ghee 3kg, emulsifier 0.5kg, custard sauce 1.5kg; the auxiliary materials include modified starch, fresh milk powder, salt , glucono-δ-lactone; the ingredients of the compound enzyme preparation include: edible corn starch, flour, food additives; food additives include: xylan, hemicellulase, calcium sulfate, glucose oxidase, vitamin C , lipase, amylase;

[0051] (2) Dough making:...

Embodiment 3

[0059] Shredded bread, prepared by:

[0060] (1) Ingredients: Weigh the raw materials of shredded bread: 42kg of flour, 10kg of powdered sugar, 0.6kg of whole milk powder, 1.2kg of fructose syrup, 1.0kg of dry yeast, 10kg of sweet flake oil, 17.485kg of water, and A5. 2kg and 5.6kg of material B; the raw materials of small material water include: water 16kg, compound enzyme preparation 0.4kg, excipients 1kg, calcium propionate 0.07kg, sodium dehydroacetate 0.015kg; the raw materials of material A include: sorbitol 1kg , glycerin 0.9kg, milk sauce flavor 0.3kg, egg white 3.0kg; the raw materials of material B include: ghee 2kg, emulsifier 0.6kg, custard sauce 3kg; the auxiliary materials include modified starch, fresh milk powder, salt, glucose Acid-δ-lactone; the ingredients of the compound enzyme preparation include: edible corn starch, flour, food additives; food additives include: xylan, hemicellulase, calcium sulfate, glucose oxidase, vitamin C, fat Enzymes, amylases;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com