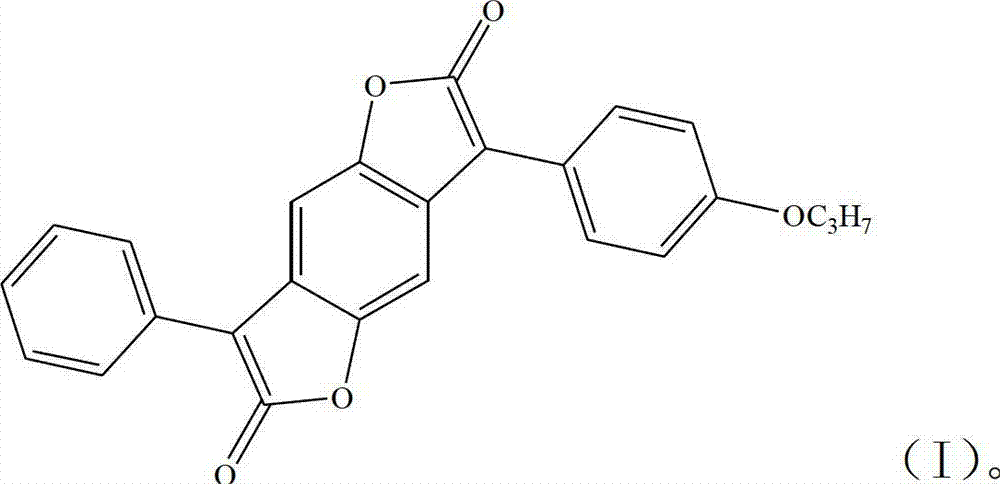

Preparation method for disperse red

A disperse red and compound technology, applied in chemical instruments and methods, organic dyes, azo dyes, etc., can solve problems such as affecting the synthesis of target products, low intermediate yields, and unfavorable industrial production, and achieve industrial operability. Strong, simple preparation, high product purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

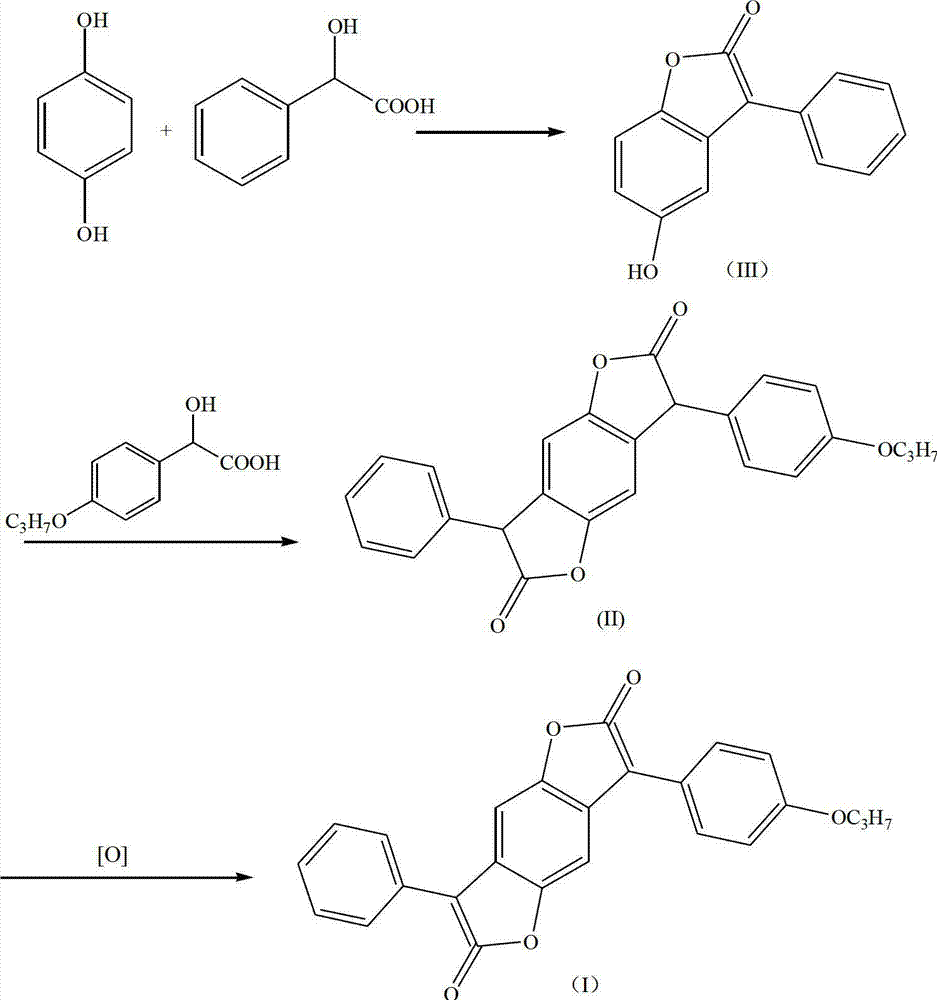

Embodiment 1

[0020] 1) Add 19.9g (0.18mol) of hydroquinone and 21.9g (0.144mol) of mandelic acid to the reactor in turn, start stirring, add 76.6g of sulfuric acid aqueous solution with a mass concentration of 75%, raise the temperature to 105°C, react for 25min, and perform HPLC It was detected that the reaction of mandelic acid was complete, cooled to 20°C, poured into ice water, stirred for 25 minutes, suction filtered, the filter cake was washed with ice water, dried in vacuo, and recrystallized with toluene to obtain 29.9 g of compound (III), with a yield of 91.4%, m.p. 158~159℃;

[0021] 2) Add 10.0g (0.044mol) of compound (III), 2000g of glacial acetic acid and 12g of phosphoric acid into the reactor, raise the temperature to 72°C, add 8.4g (0.055mol) of p-propoxymandelic acid, and control the temperature of the reaction system at 72 ℃, after the addition, keep stirring at 72℃ for 1.5h, HPLC detects that the compound (III) has reacted completely, cool to 0~5℃, filter with suction, w...

Embodiment 2

[0024] 1) Add 19.9g (0.18mol) of hydroquinone and 22.2g (0.146mol) of mandelic acid to the reactor in turn, start stirring, add 70g of sulfuric acid aqueous solution with a mass concentration of 80%, raise the temperature to 110°C, react for 20min, and detect by HPLC Mandelic acid was completely reacted, cooled to 20°C, poured into ice water, stirred for 25 min, filtered with suction, washed with ice water, dried in vacuo, recrystallized from toluene to obtain 30.1 g of compound (III), yield 92.1%, m.p.158 ~159°C;

[0025] 2) Add 10.0g (0.044mol) of compound (III), 2100g of glacial acetic acid and 11g of phosphoric acid into the reactor, raise the temperature to 75°C, add 10.1g (0.066mol) of p-propoxymandelic acid, and control the temperature of the reaction system at 75 °C, after the addition, keep stirring at 75 °C for 1.3 h, HPLC detects that the compound (III) has reacted completely, cool to 0~5 °C, filter with suction, wash the filter cake with ethanol alcohol at 0~5 °C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com