Electrolytic eutectoid alloying method for rare-earth-magnesium-nickel-based hydrogen storage alloy

A technology of hydrogen storage alloy and eutectoid alloy, which is applied in electrolysis process, electrolysis components, etc., can solve the problems of oxidation segregation, Mg volatilization, etc., and achieve the effects of low cost, adjustable composition, wide promotion and market prospect

Inactive Publication Date: 2014-11-05

GANNAN NORMAL UNIV

View PDF12 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] In order to overcome the outstanding problems of volatile and oxidative segregation of Mg in the smelting process, the technical problem to be solved by the present invention is to provide an electrolytic eutectoid alloying method for rare earth magnesium-nickel-based hydrogen storage alloys, which can effectively solve the problem of rare earth magnesium-nickel hydrogen storage The volatilization and oxidation of magnesium during the smelting process of the alloy, the composition of the rare earth magnesium-nickel hydrogen storage alloy can be adjusted and obtained stably, the electrolysis work is continuous, the production process is safe, the process is short, and the cost is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0026] Example 2:

Embodiment 2

[0028] Example 3:

Embodiment 3

[0030] Example 4:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

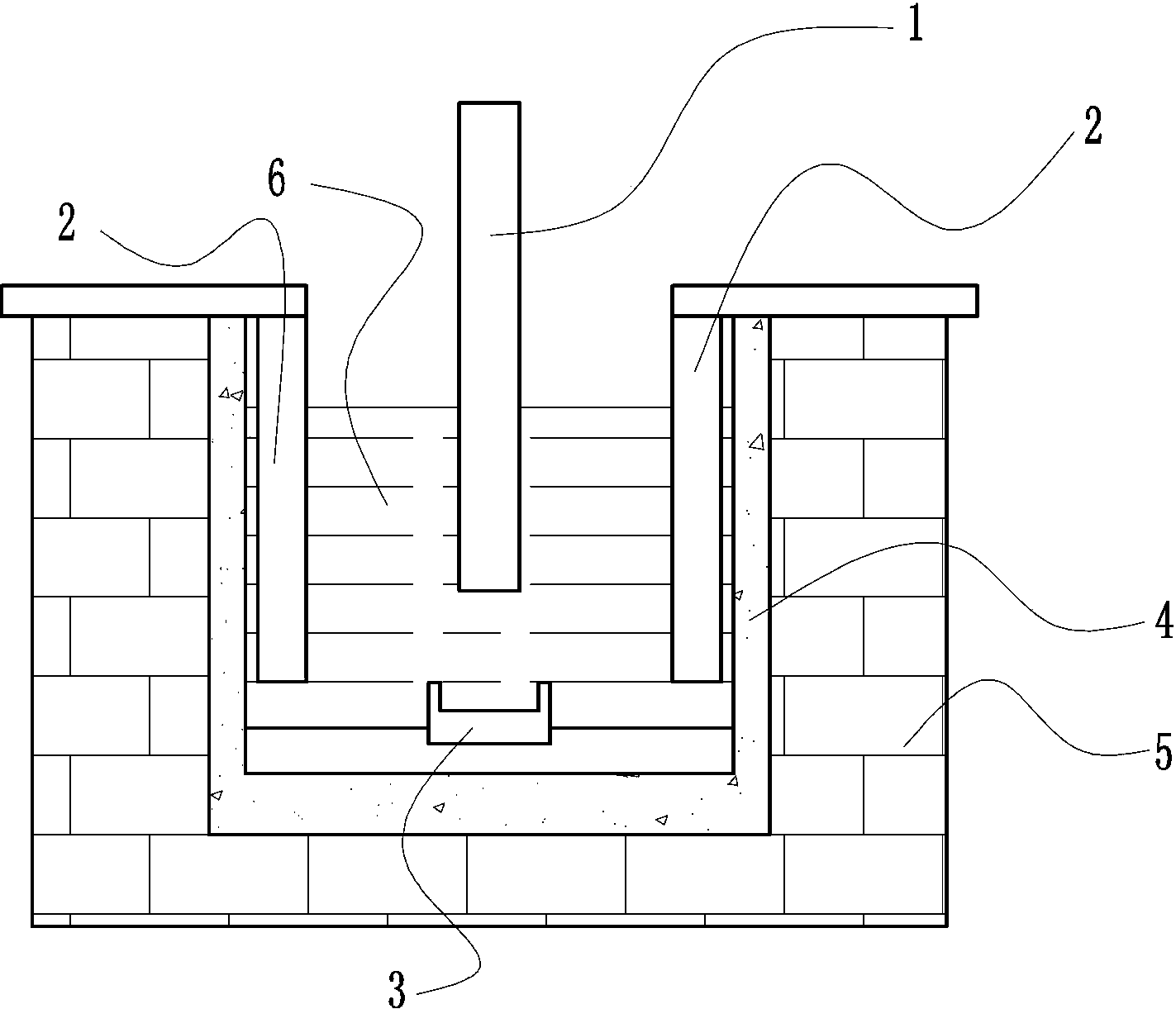

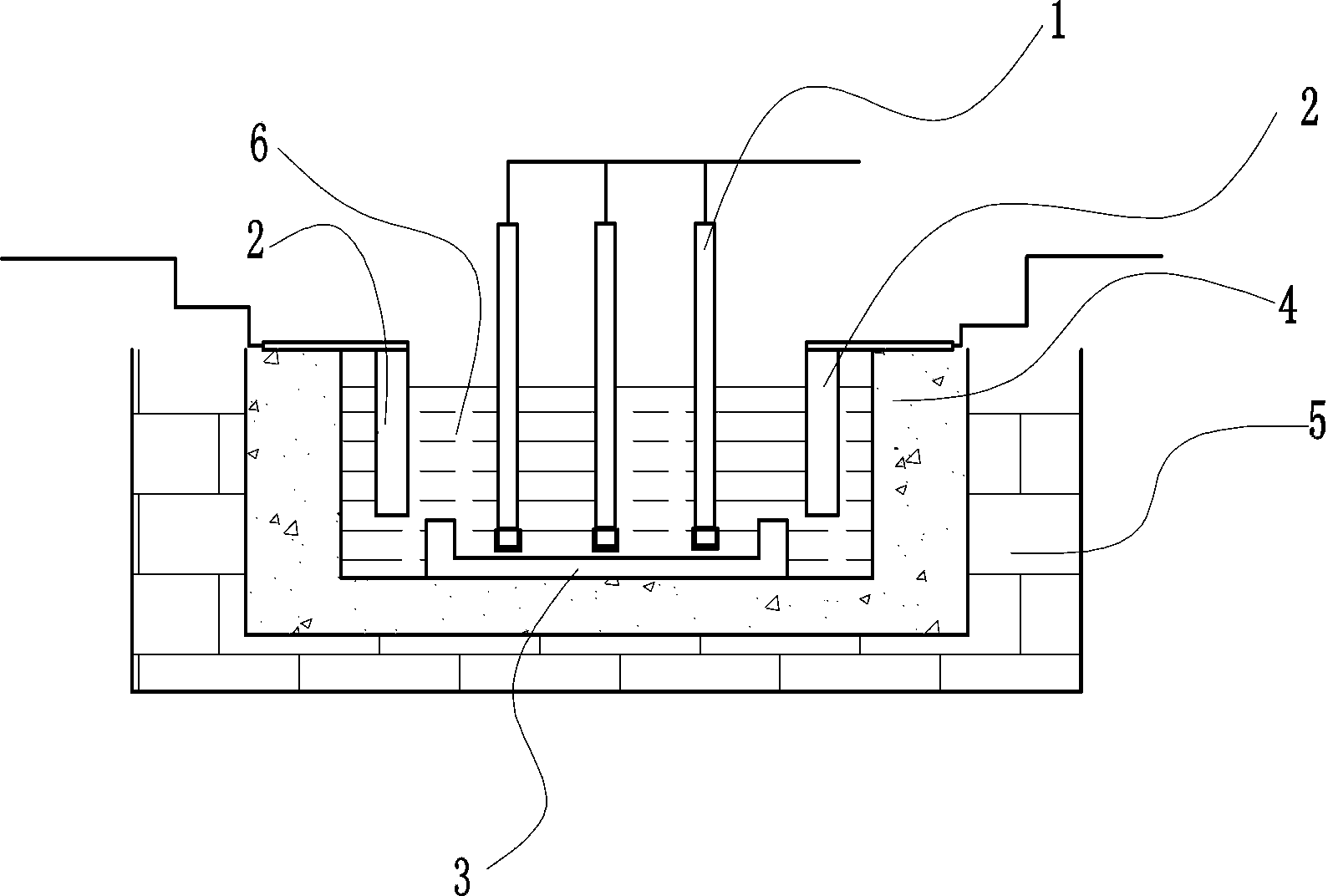

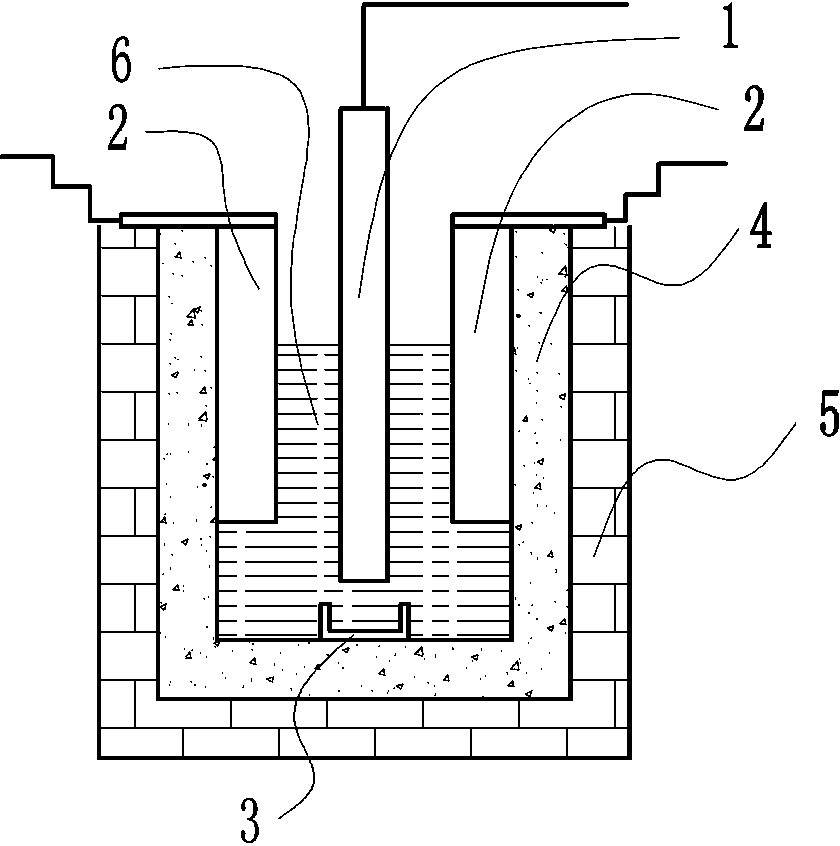

The invention belongs to the field of the preparation of rare-earth alloys and particularly relates to an electrolytic eutectoid alloying method for a rare-earth-magnesium-nickel-based hydrogen storage alloy. The electrolytic eutectoid alloying method for the rare-earth-magnesium-nickel-based hydrogen storage alloy, disclosed by the invention, comprises the steps: adopting a circular or square graphite electrolysis tank, and placing an undertake crucible at the bottom of the electrolysis tank; carrying out joint electrochemical precipitation on cathodes RE (Rare-Earth) and Mg (magnesium) in a manner of taking a metallic nickel (Ni) rod as a cathode, taking fluoride fused salts, such as REF3-LiF-MgF2-BaF2, as an electrolyte and taking a mixture of RE2O3 and MgO as a raw material, alloying with nickel which serves as a cathode, so as to obtain an RE-Mg-Ni alloy, and sinking into the undertake crucible, thereby obtaining the rare-earth-magnesium-nickel-based hydrogen storage alloy. The method has the beneficial effects that the problem that magnesium is subjected to volatilization and oxidation during the smelting of the rare-earth-magnesium-nickel-based hydrogen storage alloy is effectively solved, the rare-earth-magnesium-nickel-based hydrogen storage alloy is adjustable and controllable in ingredients and can be obtained stably, the electrolysis work is continuous, the production process is safe, the process flow is short, and the cost is low.

Description

technical field [0001] The invention belongs to the field of rare earth alloy preparation, and in particular relates to an electrolytic eutectoid alloying method for a rare earth magnesium-nickel-based hydrogen storage alloy. Background technique [0002] RE-Mg-Ni series hydrogen storage alloy is a new generation of high-performance rare earth hydrogen storage material developed in recent years. Depending on the composition, its hydrogen storage weight hydrogen storage density is between 1.4-6%, and its comprehensive performance is superior. There are many preparation techniques for RE-Mg-Ni alloys. On the whole, there are mainly high-temperature diffusion sintering techniques, such as CN1271025A, CN1296083A, CN1598018A, CN1900337A; vacuum induction melting techniques, such as CN1397658A, CN102191416A, CN102277508A, CN102286684A; Such as CN1316537A, CN1644737A; vacuum rapid quenching technology, such as CN101624660, CN101626076A; [0003] Due to the high activity and volati...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25C3/36C25C7/06

Inventor 彭光怀杜西龙郭华彬

Owner GANNAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com