Contact lens care solution and preparation method

A contact lens and care solution technology, applied in chemical instruments and methods, pharmaceutical formulations, medical preparations containing active ingredients, etc., can solve problems such as dry eyes, corneal loss, inflammation, and eye injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0121] The application also provides a preparation method of contact lens care solution, comprising the following steps:

[0122] Step 1: Add water for injection in the dissolving tank;

[0123] Step 2: Add the moisturizing agent into the dissolving tank while stirring, and stir until completely dissolved;

[0124] Step 3: Mix ectoine or ophthalmologically acceptable ectoine derivatives, surfactants, antibacterial agents, moisturizing agents, buffers, osmotic pressure regulators, and chelating agents, and then slowly add to In the dissolving tank, stir to make it all dissolve to obtain mixed solution 1;

[0125] Step 4: Using hydrochloric acid or sodium hydroxide to adjust the pH of the mixed solution 1 to obtain the mixed solution 2;

[0126] Step 5: The mixed solution in the dissolution tank is filtered, and the filtered liquid is a contact lens care solution.

[0127] In this application, the water in the dissolving tank is heated to 80-85°C before adding the moisturizin...

Embodiment 1

[0137] Add water for injection in the dissolving tank; the molecular weight is 1.3×10 6 Da and 0.3×10 6 Da sodium hyaluronate (1.3 x 10 6 Da and 0.3×10 6 The mass ratio of Da is 1:4) into the dissolution tank while stirring, and stir until completely dissolved; 0.01g ectoine, 0.01g poloxamer 407, 0.05g dipotassium glycyrrhizinate, 0.005g borate Buffer, 0.01g sodium chloride, and 0.001g EDTA-2Na are mixed evenly, then slowly added to the dissolution tank, stirred to make them all dissolve, and mixed solution 1 is obtained; the pH of the mixed solution 1 is adjusted to 7.2 with hydrochloric acid , Obtain mixed solution two; Mixed solution two in the described dissolving tank is filtered, and the liquid that obtains after filtering is contact lens care solution, and the osmotic pressure of described contact lens care solution is 290mOsm / L, and concrete parameter is as shown in table 1.

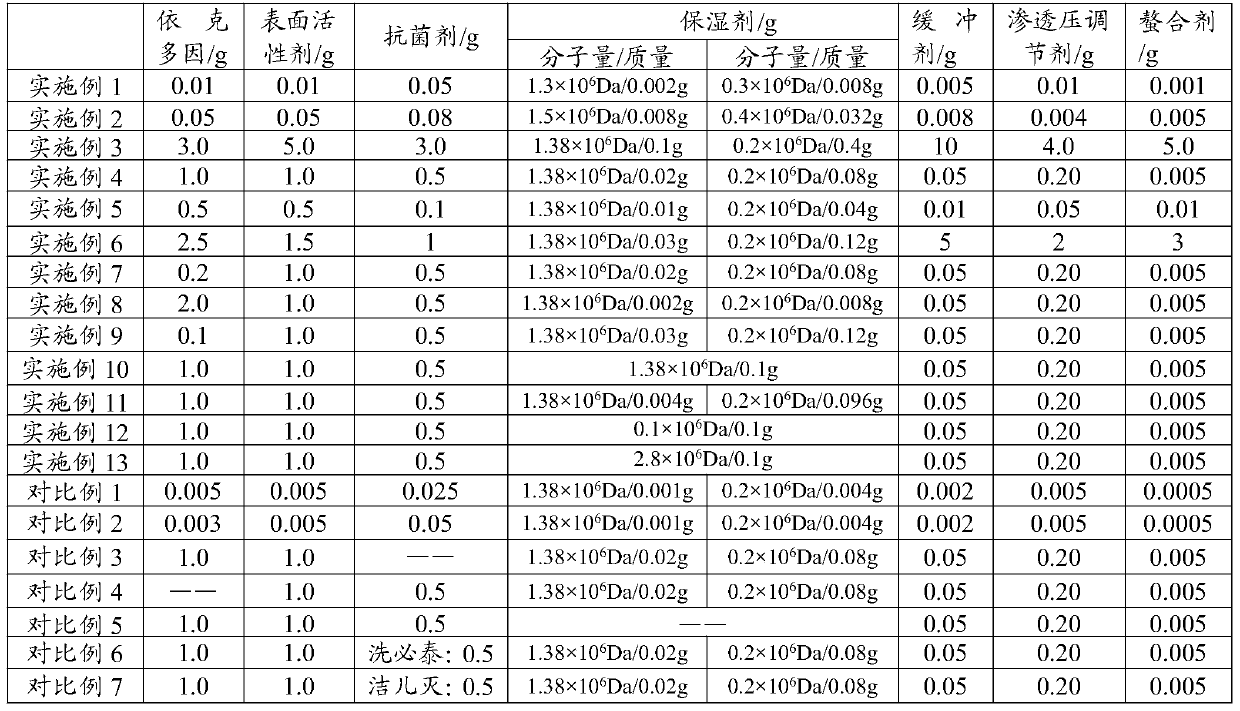

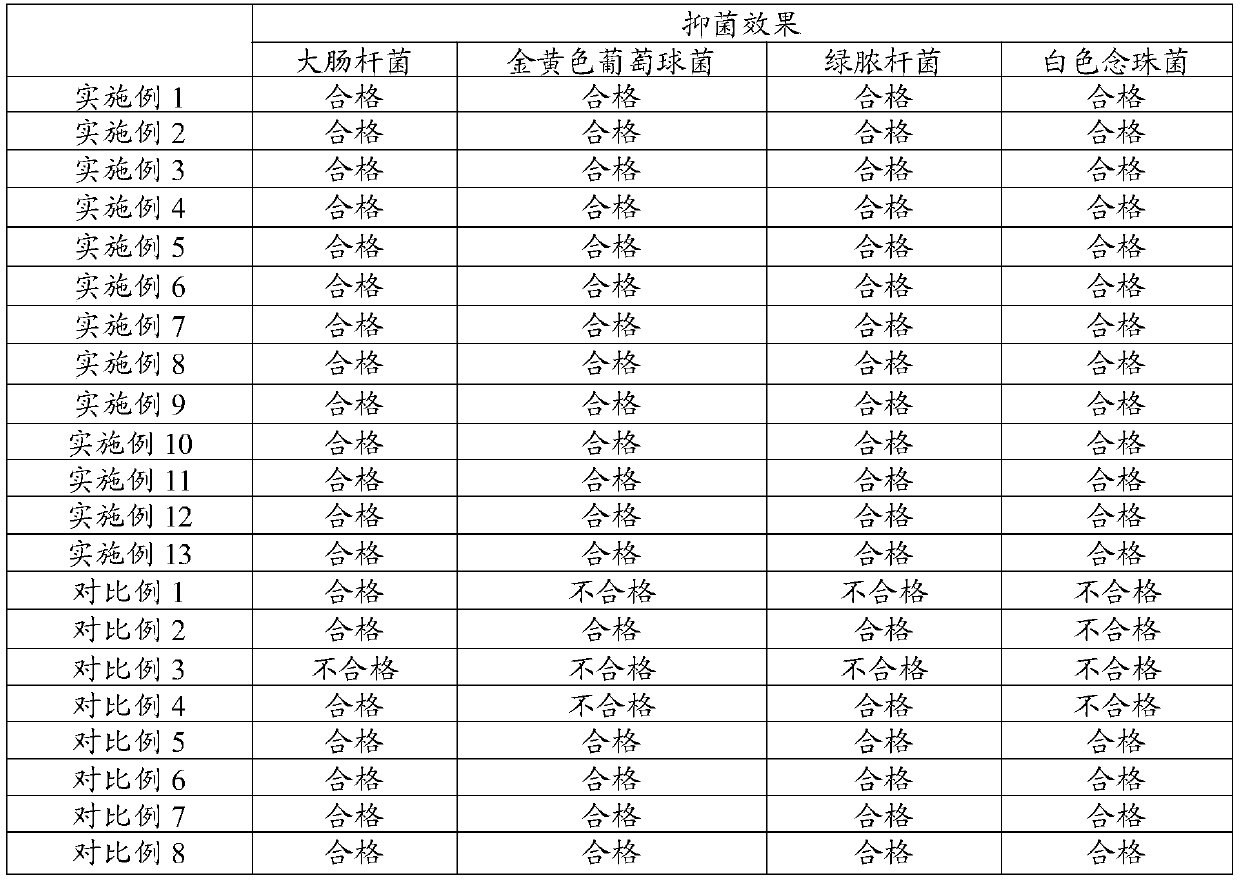

[0138] Embodiment 2-Example 9 and Comparative Example 1-Comparative Example 2 are differen...

Embodiment 10

[0139] The difference between Example 10 and Example 4 is that there is only one molecular weight of sodium hyaluronate in Example 10, and the specific parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com