Method and device for preparing nano silver- and porous structure-containing medical high molecular material

A technology of polymer materials and porous structures, applied in the direction of catheters, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

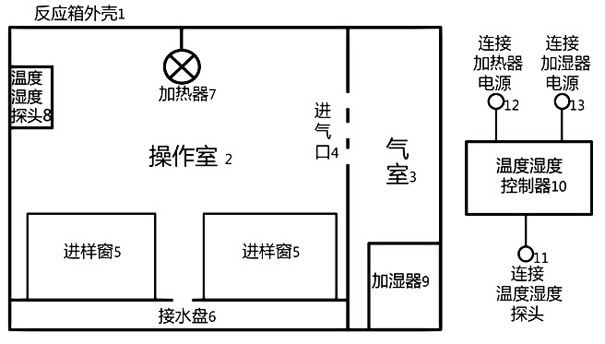

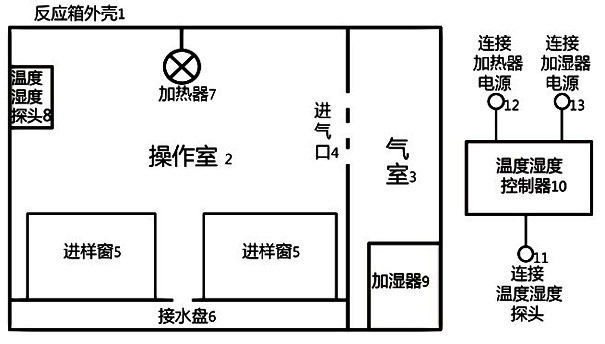

Image

Examples

Embodiment 1

[0041] Dissolve 1 g of medical polyurethane masterbatch in 50 ml of tetrahydrofuran. Add 0.1 g of silver nitrate, and add 1 ml (0.001 g / m1) of sodium borohydride ethanol solution under vigorous stirring to prepare a nano-silver / polymer composite solution for use.

[0042] Select commercially available ordinary PVC conduits, wash and dry them, immerse them in the composite solution for 30 seconds, take them out, and place them in a constant temperature and humidity reactor with a humidity of 90% at 25°C to naturally volatilize to form a film for about 5-10 minutes. The nano-silver / polymer honeycomb structure-coated antibacterial catheter was prepared. The average thickness of the coating was 50 μm, the average pore size of the honeycomb structure was about 5 μm, and the silver content was 10%.

Embodiment 2

[0044] Dissolve 1 g of medical polyurethane masterbatch in 50 ml of tetrahydrofuran. Add 0.1 g of silver nitrate, and add 1 ml (0.001 g / m1) of sodium borohydride ethanol solution under vigorous stirring to prepare a nano-silver / polymer composite solution for use.

[0045] Select a commercially available common polyurethane catheter, after washing and drying, immerse in the composite solution for 30 seconds, take it out, and in a constant temperature and humidity reactor, with a humidity of 60%, at 25°C, naturally volatilize to form a film, about 5-10 minutes, The nano-silver / polymer honeycomb structure-coated antibacterial catheter was prepared. The average thickness of the coating was 50 μm, the average pore size of the honeycomb structure was about 3 μm, and the silver content was 10%.

Embodiment 3

[0047] Dissolve 1 g of medical polyurethane masterbatch in 50 ml of tetrahydrofuran. Add 0.1 g of silver nitrate, and add 1 ml (0.001 g / m1) of sodium borohydride ethanol solution under vigorous stirring to prepare a nano-silver / polymer composite solution for use.

[0048] Select a commercially available ordinary polyurethane catheter, wash and dry it, immerse it in the composite solution for 30 seconds, take it out, and naturally volatilize and form a film in a constant temperature and humidity reactor with a humidity of 90% at 40°C for about 5-10 minutes. The nano-silver / polymer honeycomb structure-coated antibacterial catheter was prepared. The average thickness of the coating was 50 μm, the average pore size of the honeycomb structure was about 3 μm, and the silver content was 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com