Environmental-friendly organic profile control agent and preparation method and use thereof

A profile control agent, organic technology, applied in the field of oil and gas development, can solve the problems of strong adhesion, low density and high density of water blocking agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

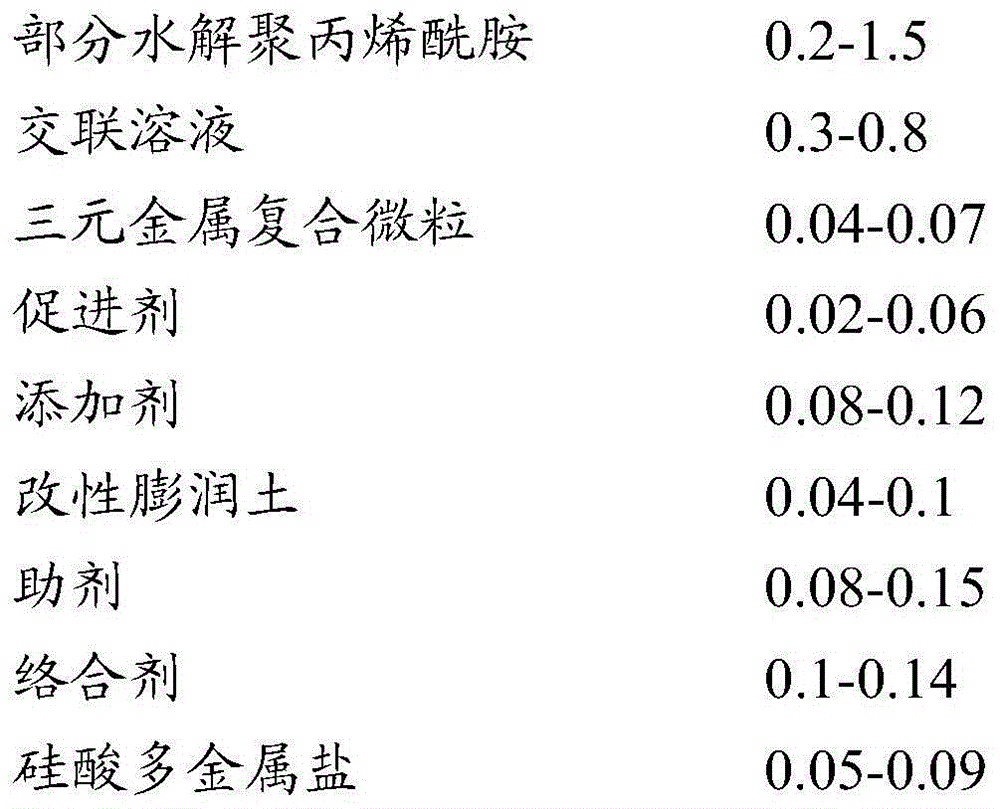

Method used

Image

Examples

preparation example 1

[0078] S1: In the presence of sodium sulfide, m-diisopropylbenzene is oxidized with continuously fed oxygen at 30°C in a reaction kettle, and the reaction time is 50 minutes, thereby obtaining diisopropylbenzene peroxide; Then add an appropriate amount of hydrochloric acid aqueous solution with a concentration of 15% by mass percentage, fully stir to obtain the intermediate reaction product and acetone, and remove the acetone;

[0079] Wherein the mass ratio of sodium sulfide and m-diisopropylbenzene is 0.2:100;

[0080] S2: Add formaldehyde aqueous solution with a mass percent concentration of 25% to the intermediate reaction product for reaction, the reaction time is 6 hours, and the reaction temperature is 50°C; after the reaction is completed, the water layer is removed, and then a mixture of acetone and ethanol is added to the remaining system. volume mixture and water, fully stirred evenly, to obtain the cross-linking solution, which is named JL1;

[0081] Wherein the mol...

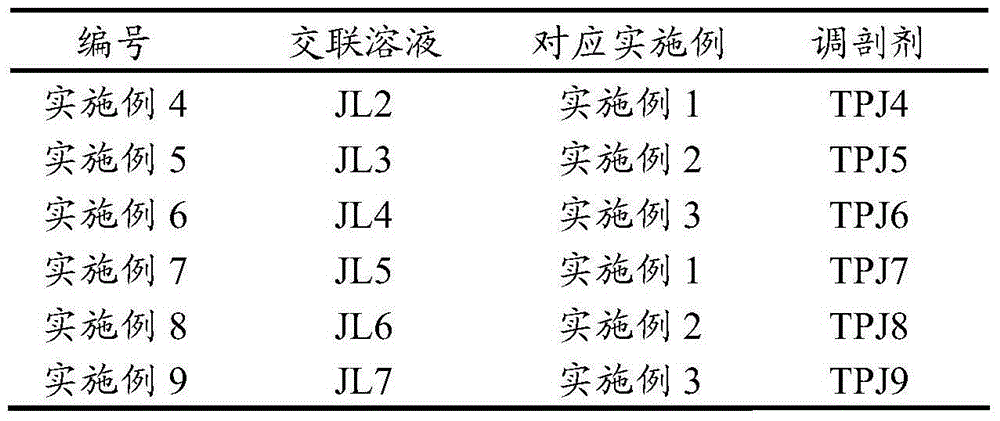

preparation example 2-7

[0085] Except that the inorganic base in the crosslinking solution preparation example 1 is replaced by KOH, NaOH, sodium carbonate, sodium sulfate, potassium carbonate or sodium phosphate respectively by sodium sulfide respectively, other operations are all unchanged, thus the corresponding crosslinking solution obtained, Named sequentially as JL2-JL7.

[0086] Preparation Example of Ternary Metal Composite Particles

[0087] (1) prepare respectively the magnesium nitrate aqueous solution of 1mol / L, the aluminum sulfate aqueous solution of 1mmol / L and the potassium chloride aqueous solution of 1mmol / L;

[0088] (2) Slowly add NaOH aqueous solution in sodium phosphate aqueous solution, the aqueous solution that preparation NaOH concentration is 2mol / L and sodium phosphate concentration is 0.5mol / L;

[0089] (3) Add the magnesium nitrate aqueous solution, aluminum sulfate aqueous solution and potassium chloride aqueous solution of step (1) sequentially to the aqueous solution ...

preparation example

[0092] 1, bentonite was calcined at 550° C. for 25 minutes, then cooled to room temperature, and pulverized, ground, and crossed a 300 mesh sieve to obtain bentonite powder;

[0093] II. Stir bentonite powder, dimethyl dodecyl ammonium chloride and deionized water evenly, react at 55°C for 150 minutes, then filter and vacuum dry to obtain the modified bentonite, which is named PRT;

[0094] Wherein, the mass ratio of bentonite powder, dimethyl dodecyl ammonium chloride and deionized water is 1:2:15.

[0095] Silicic acid polymetallic salt preparation example 1

[0096] (1) Adding an aqueous solution of sulfuric acid with a mass percentage concentration of 15% to a sodium silicate aqueous solution with a mass percentage concentration of 2% to adjust pH=4-5, then stirring at room temperature for 20 minutes to obtain an acidic aqueous solution;

[0097] (II) Add aluminum sulfate, zinc nitrate and titanium chloride to the acidic aqueous solution, and stir evenly, then heat up to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com