Preparation method of antibacterial dressing

A raw material and solution technology, applied in the field of medical supplies, can solve the problem of low antibacterial efficacy, achieve excellent antibacterial performance, and the effect of environmentally friendly ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method for an antibacterial dressing, comprising the steps of:

[0024] Step S1. Weigh the following raw materials in parts by weight: 25 parts by mass of 15% silver nitrate solution, 10 parts of bamboo fiber, 1 part of polyvinylpyrrolidone, 3 parts of antibacterial precursor, and 50 parts of deionized water.

[0025] Step S2, put the silver nitrate solution with a mass fraction of 15% and bamboo fibers into a steam pressure vessel, heat to 120°C, keep warm and react for 30 minutes, cool, wash with deionized water three times, dry to obtain composite fibers, and cool to room temperature;

[0026] Step S3, placing the composite fiber in a carbonization furnace, introducing nitrogen gas to discharge the air, raising the temperature to 500° C. at a heating rate of 10° C. / min, and carbonizing at this temperature for 30 minutes to obtain a carbonized fiber;

[0027] Step S4, add polyvinylpyrrolidone to deionized water, stir magnetically at a speed of 100r / min ...

Embodiment 2

[0032] A preparation method for an antibacterial dressing, comprising the steps of:

[0033] Step S1, weighing the following raw materials in parts by weight: 28 parts by mass fraction of 15% silver nitrate solution, 14 parts of bamboo fiber, 3 parts of polyvinylpyrrolidone, 5 parts of antibacterial precursor, and 55 parts of deionized water.

[0034]Step S2, put the silver nitrate solution with a mass fraction of 15% and bamboo fibers into a steam pressure vessel, heat to 120°C, keep warm and react for 30 minutes, cool, wash with deionized water three times, dry to obtain composite fibers, and cool to room temperature;

[0035] Step S3, placing the composite fiber in a carbonization furnace, introducing nitrogen gas to discharge the air, raising the temperature to 500° C. at a heating rate of 10° C. / min, and carbonizing at this temperature for 30 minutes to obtain a carbonized fiber;

[0036] Step S4, add polyvinylpyrrolidone to deionized water, stir magnetically at a speed ...

Embodiment 3

[0041] A preparation method for an antibacterial dressing, comprising the steps of:

[0042] Step S1, weighing the following raw materials in parts by weight: 30 parts by weight of 15% silver nitrate solution, 18 parts of bamboo fiber, 4 parts of polyvinylpyrrolidone, 6 parts of antibacterial precursor, and 70 parts of deionized water.

[0043] Step S2, put 15% silver nitrate solution and bamboo fibers into a steam pressure vessel, heat to 120-130°C, keep warm and react for 30 minutes, cool, wash with deionized water three times, and dry to obtain composite fibers , cooled to room temperature;

[0044] Step S3, placing the composite fiber in a carbonization furnace, introducing nitrogen gas to discharge the air, raising the temperature to 500° C. at a heating rate of 10° C. / min, and carbonizing at this temperature for 30 minutes to obtain a carbonized fiber;

[0045] Step S4, add polyvinylpyrrolidone to deionized water, stir magnetically at a speed of 100r / min for 30min to pr...

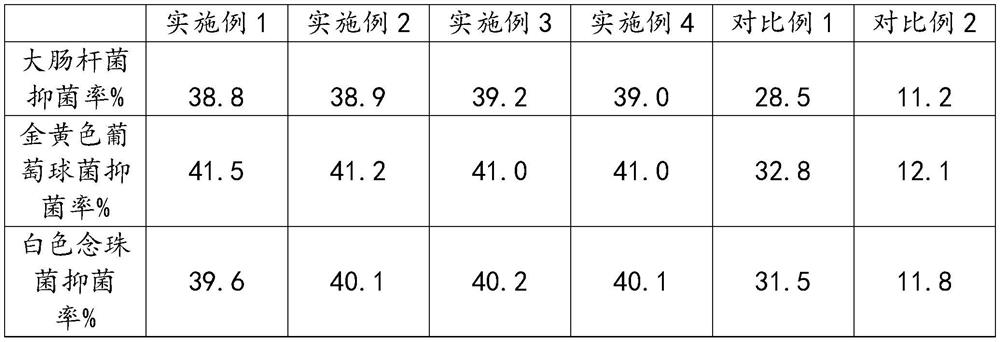

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com