Preparation method of heat-insulating and noise-resisting tempered glass

A kind of tempered glass, noise-type technology, applied to the device, coating, special surface and other directions of coating liquid on the surface, can solve the problems of increased thickness, low applicability, unsuitable tempered glass, etc., to improve the structural strength , Improve the thermal insulation effect, the effect of small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

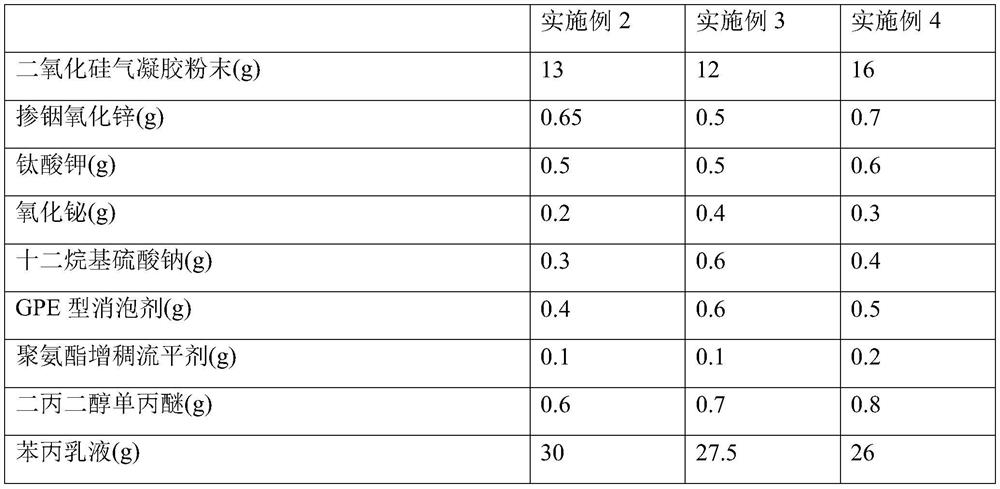

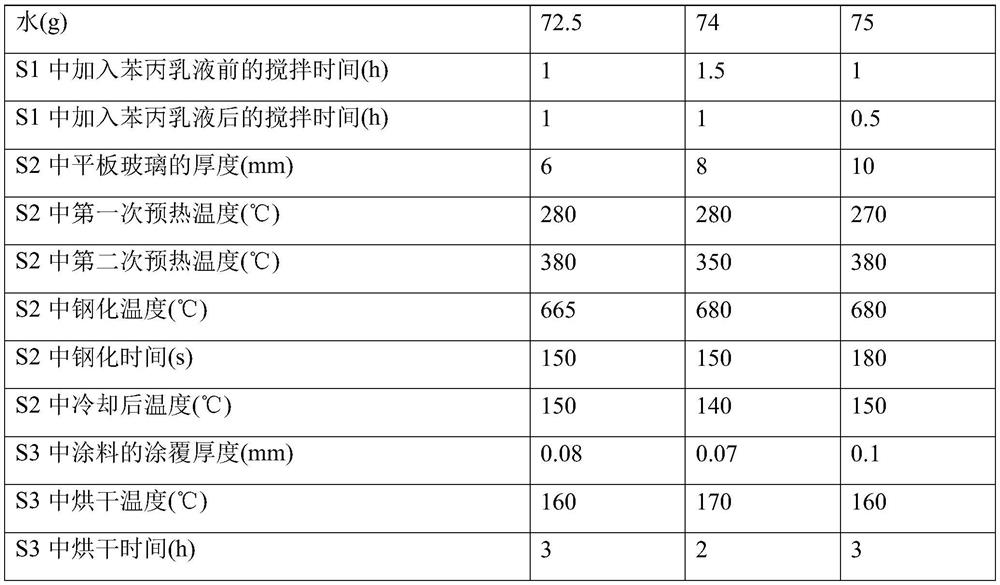

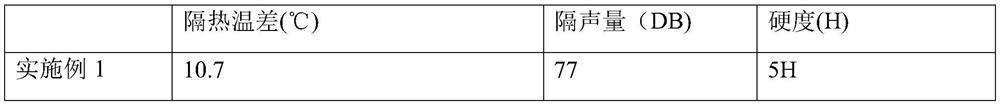

Examples

preparation example 1

[0059] Preparation of silica airgel powder:

[0060] Add 20g of tetraethyl orthosilicate, 80g of ethanol and 30g of water into the reaction flask and mix to form a mixed solution. Stir and disperse with a mechanical stirrer for 20 minutes. The stirring temperature is 50°C. Add 1mol / L hydrochloric acid to adjust the pH of the mixed solution to 3. Continue Stir for 3 hours, add 1mol / L ammonia water to adjust the pH of the mixture to 7, continue to stir for 2 minutes, naturally cool to room temperature, and let it stand for 1.5 hours to obtain a silica wet gel, immerse the silica wet gel in water for 30 minutes , and then add ethanol equal to the volume of water to continue soaking the silica wet gel for 12 hours, take out the silica wet gel, dry it in a 50°C oven for 1 hour, and grind to obtain silica airgel powder.

preparation example 2

[0062] Preparation of silica airgel powder:

[0063] Add 30g of tetraethyl orthosilicate, 60g of ethanol and 40g of water into the reaction flask and mix to form a mixed solution. Stir and disperse with a mechanical stirrer for 15 minutes. The stirring temperature is 60°C. Add 1mol / L hydrochloric acid to adjust the pH of the mixed solution to 4. Continue Stir for 2 hours, add 1mol / L ammonia water to adjust the pH of the mixture to 8, continue to stir for 3 minutes, naturally cool to room temperature, and let it stand for 1.5 hours to obtain a silica wet gel, immerse the silica wet gel in water for 30 minutes , and then add ethanol equal to the volume of water to continue soaking the silica wet gel for 18 hours, take out the silica wet gel, dry it in a 50°C oven for 1 hour, and grind to obtain silica airgel powder.

Embodiment 1

[0066] Preparation method of heat-insulating and anti-noise tempered glass;

[0067] S1. Take 10g of silica airgel powder, 0.8g of indium-doped zinc oxide with a particle size of 20-30nm, 0.4g of potassium titanate, 0.3g of bismuth oxide, 0.2g of dispersant, 0.2g of defoamer, 0.3g Leveling agent, 0.6g film-forming aid and 70g water were added to the reaction kettle, dispersed and stirred by a mechanical stirrer at 800r / min for 0.5h, then 25g of styrene-acrylic emulsion was added, and stirred at 1000r / min for 0.5h, Obtain heat insulation and anti-noise coating;

[0068] S2. Take flat glass with a length and width of 500mm and a thickness of 5mm, put the flat glass into a glass preheating furnace for the first preheating, the preheating time is 30s, the preheating temperature is 270°C, and then the preheating temperature Rise to 350°C and carry out the second preheating, the preheating time is 30s, and then put the flat glass into the tempering furnace for tempering for 180s, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com