Water borne epoxy resin anticorrosive paint and preparation method thereof

A technology of water-based epoxy resin and anti-corrosion coatings, which is applied in the direction of epoxy resin coatings, anti-corrosion coatings, coatings, etc., to achieve the effects of wide application range, good water resistance, and sufficient sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

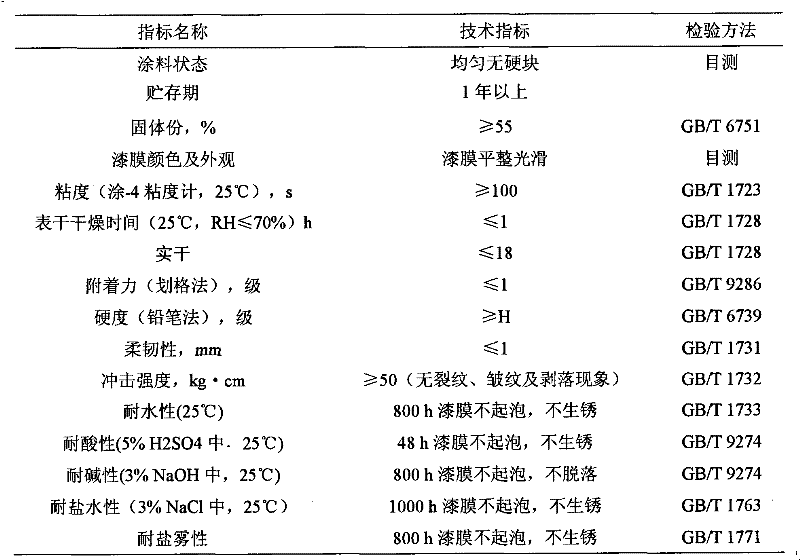

Embodiment 1

[0032] The waterborne epoxy resin anticorrosion coating of the present embodiment is made up of each component of following mass percentage:

[0033] Silicone modified water-based epoxy resin dispersion 40%, iron oxide red 15%, anti-rust pigment titanium iron powder 8%, talcum powder 15%, defoamer 0.2%, leveling agent 0.2%, anti-flash rust agent Phosphate mixture 0.4%, deionized water 21.2%. The mass percentage is the percentage of the total mass of the coating taken by weighing.

[0034] Wherein the preparation method of siloxane modified aqueous epoxy resin dispersion liquid, its detailed steps are as follows:

[0035] (1) take by weighing each monomer and initiator of following mass percent: methacrylic acid 24%, methyl methacrylate 38%, styrene 36%, benzoyl peroxide 2%; Described mass percent is accounted for all Take the percentage of total monomer mass;

[0036] (2) In a four-necked flask equipped with agitator, condensing tube, nitrogen conduit, dropping funnel, pre-...

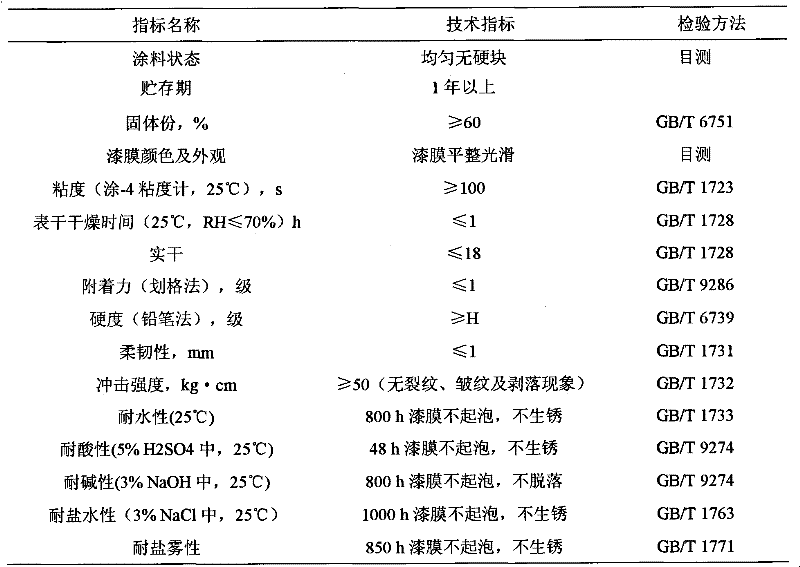

Embodiment 2

[0044] The waterborne epoxy resin anticorrosion coating of the present embodiment is made up of each component of following mass percentage:

[0045]Silicone modified water-based epoxy resin dispersion 48%, iron oxide red 15%, anti-rust pigment titanium iron powder 10%, talcum powder 15%, defoamer 0.3%, leveling agent 0.3%, anti-flash rust agent Phosphate mixture 0.4%, deionized water 11%. The mass percentage is the percentage of the total mass of the coating taken by weighing.

[0046] Wherein the preparation method of siloxane modified aqueous epoxy resin dispersion liquid is the same as embodiment 1.

[0047] According to above-mentioned formula, adopt the preparation method of embodiment 1, make waterborne epoxy resin anticorrosion coating.

[0048] The water-based epoxy anticorrosion coating obtained in this embodiment is used for the anticorrosion primer of the storage tank, and the coating film dries quickly, and the paint film is tough and durable, with good adhesion...

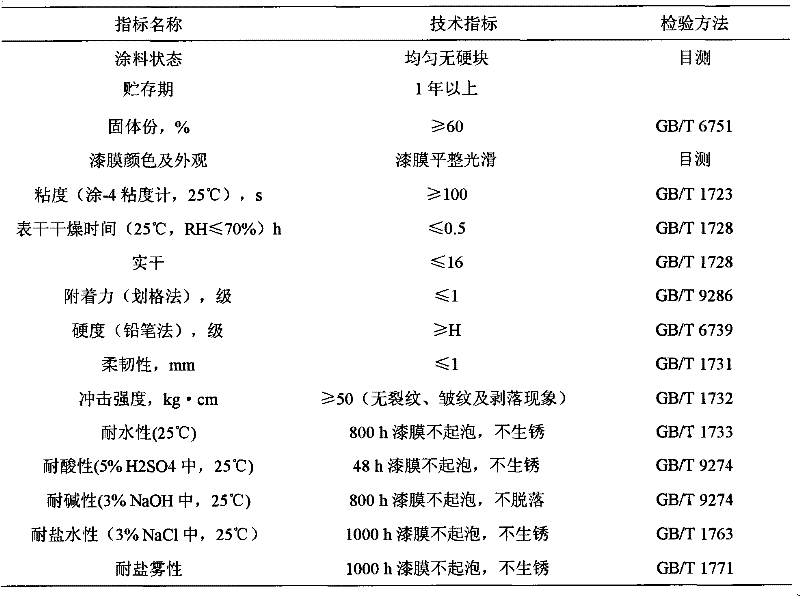

Embodiment 3

[0051] The waterborne epoxy resin anticorrosion coating of the present embodiment is made up of each component of following mass percentage:

[0052] Siloxane modified water-based epoxy resin dispersion 55%, iron oxide red 10%, anti-rust pigment titanium iron powder 10%, talcum powder 15%, defoamer 0.3%, leveling agent 0.3%, anti-flash rust agent Phosphate mixture 0.4%, deionized water 9%. The mass percentage is the percentage of the total mass of the coating taken by weighing.

[0053] Wherein the preparation method of siloxane modified aqueous epoxy resin dispersion liquid is the same as embodiment 1.

[0054] According to above-mentioned formula, adopt the preparation method of embodiment 1, make waterborne epoxy anticorrosion coating.

[0055] The water-based epoxy resin anticorrosion coating obtained in this embodiment is used for the anticorrosion primer of the bridge deck. The paint film is tough and wear-resistant, has good adhesion, strong water penetration resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com