Interior-wall heat-preservation radiation-resistant diatom ooze and preparing method thereof

A technology of anti-radiation and diatom mud, which is applied in the field of building materials, can solve problems such as uneven quality, poor adhesion, and many brands, and achieve the effects of good color matching, light bulk density, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

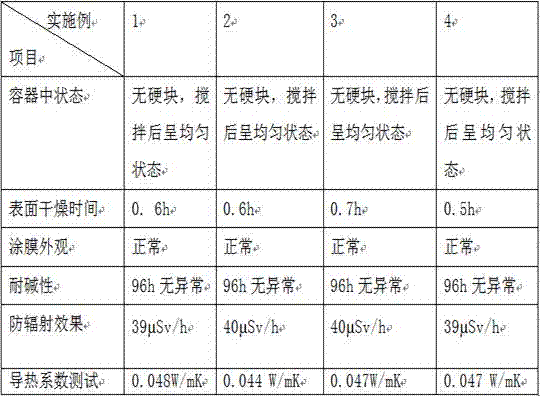

Examples

Embodiment 1

[0066] The production method of inner wall thermal insulation and radiation-proof diatom mud, which includes the following raw materials in parts by weight: 60 parts of diatomite, 10 parts of expanded perlite, 15 parts of epoxy resin, 15 parts of cobalt naphthalate, and 5 parts of calcite powder , 5 parts of anti-radiation material, 2 parts of defoamer, 1 part of thickener, 2 parts of dispersant, 2 parts of wetting agent AP-680, 45 parts of water;

[0067] The production process of inner wall insulation and anti-radiation diatom mud includes the following steps:

[0068] (1) Add parts by weight of cobalt naphthenate, anti-radiation material, 1 / 2 defoamer, thickener, dispersant, wetting agent AP-680, 1 / 3 water, mix and stir, Stir evenly, at a speed of 300 rpm, and stir for 10 minutes;

[0069] (2), add expanded perlite and calcite powder to step (1), mix and stir, stir evenly, at a speed of 500 rpm, and stir for 20 minutes;

[0070] (3) Finally, add diatomaceous earth, epoxy ...

Embodiment 2

[0079] The production method of inner wall thermal insulation and radiation-proof diatom mud, which includes the following raw materials in parts by weight: 70 parts of diatomite, 15 parts of expanded perlite, 20 parts of epoxy resin, 17 parts of cobalt naphthalate, and 6 parts of calcite powder , 7 parts of anti-radiation material, 3 parts of defoamer, 2 parts of thickener, 3 parts of dispersant, 3 parts of wetting agent AP-680, 55 parts of water;

[0080] The production process of inner wall insulation and anti-radiation diatom mud includes the following steps:

[0081] (1) Add parts by weight of cobalt naphthenate, anti-radiation material, 1 / 2 defoamer, thickener, dispersant, wetting agent AP-680, 1 / 3 water, mix and stir, Stir evenly, at a speed of 400 rpm, and stir for 12 minutes;

[0082] (2) Add expanded perlite and calcite powder to step (1), mix and stir, stir evenly, at a speed of 600 rpm, and stir for 22 minutes;

[0083] (3) Finally, add diatomaceous earth, epoxy ...

Embodiment 3

[0092] The production method of inner wall thermal insulation and radiation-proof diatom mud, which includes the following raw materials in parts by weight: 80 parts of diatomite, 15 parts of expanded perlite, 25 parts of epoxy resin, 18 parts of cobalt naphthalate, and 7 parts of calcite powder , 8 parts of anti-radiation material, 3 parts of defoamer, 3 parts of thickener, 4 parts of dispersant, 3 parts of wetting agent AP-680, 55 parts of water;

[0093] The production process of inner wall insulation and anti-radiation diatom mud includes the following steps:

[0094] (1) Add parts by weight of cobalt naphthenate, anti-radiation material, 1 / 2 defoamer, thickener, dispersant, wetting agent AP-680, 1 / 3 water, mix and stir, Stir evenly, at a speed of 400 rpm, and stir for 14 minutes;

[0095] (2), add expanded perlite and calcite powder to step (1), mix and stir, stir evenly, at a speed of 700 rpm, and stir for 25 minutes;

[0096] (3) Finally, add diatomaceous earth, epoxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com