Ethylene series polymer composition for high-speed stretching making film and method for mfg. porous film

An ethylene-based and polymer technology, which is applied in the field of high-speed stretching film-making ethylene-based polymer compositions and the manufacture of porous films, can solve problems such as improving high-speed stretching film-making properties, and achieves excellent appearance, good flexibility, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

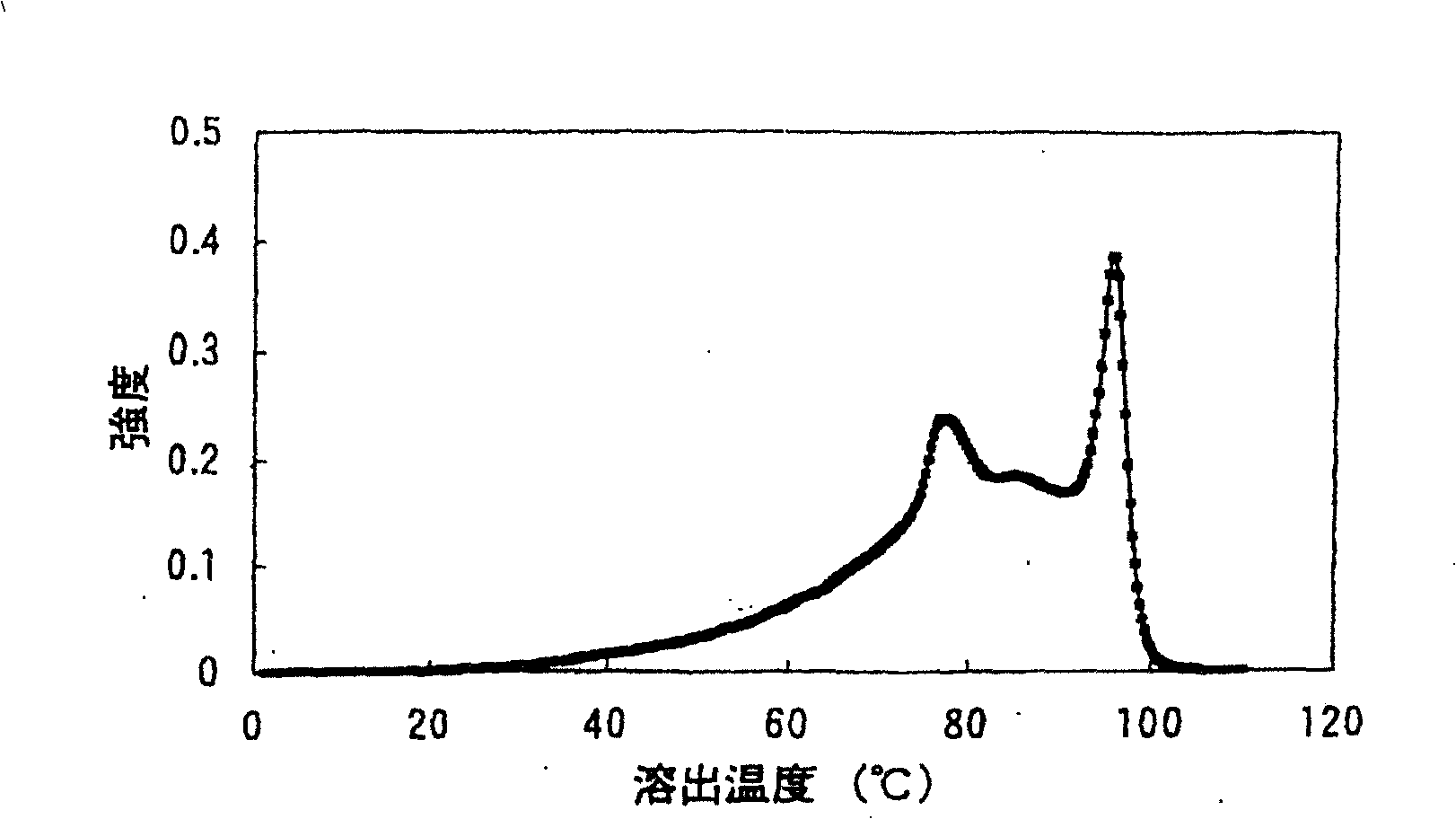

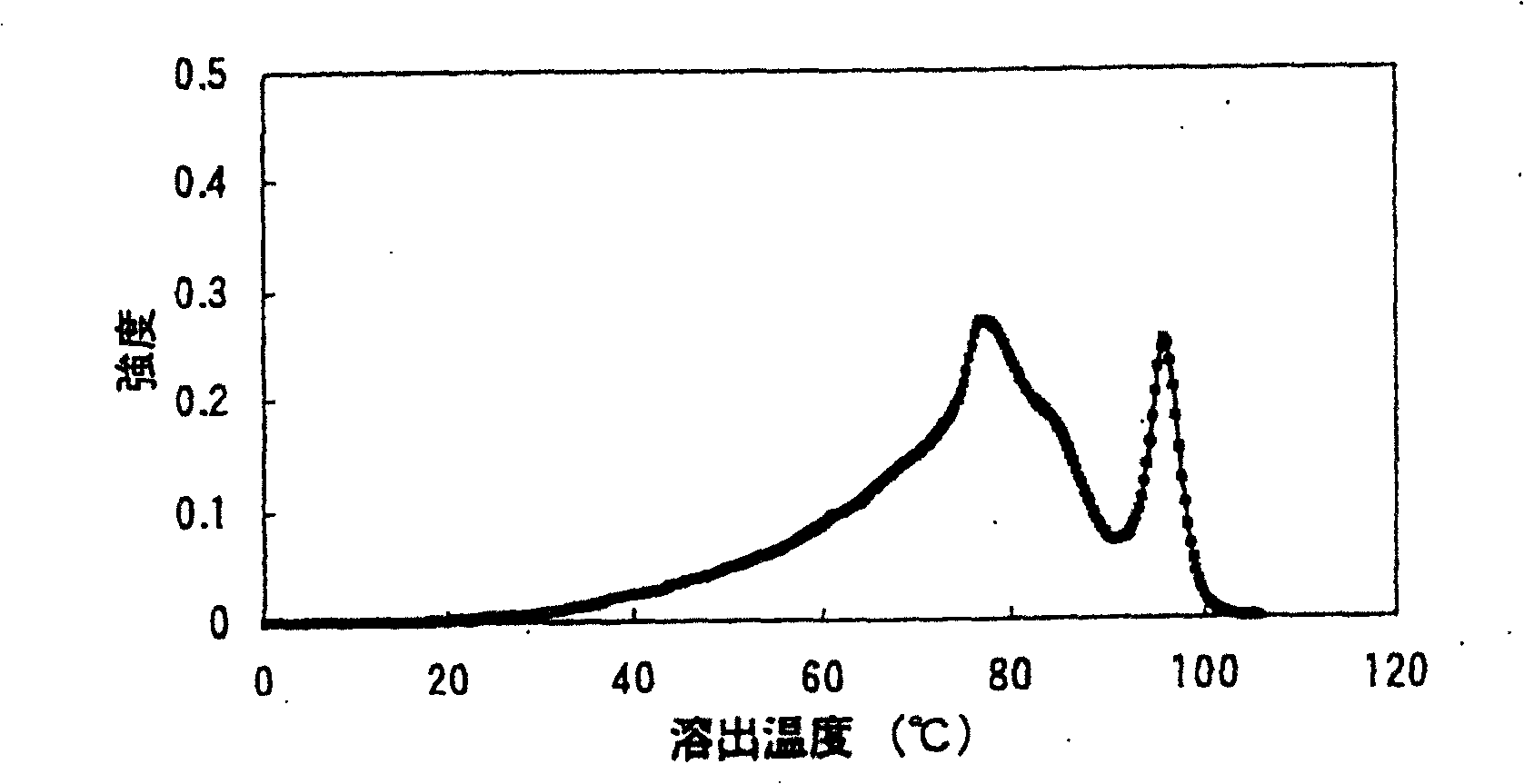

Image

Examples

Embodiment 1

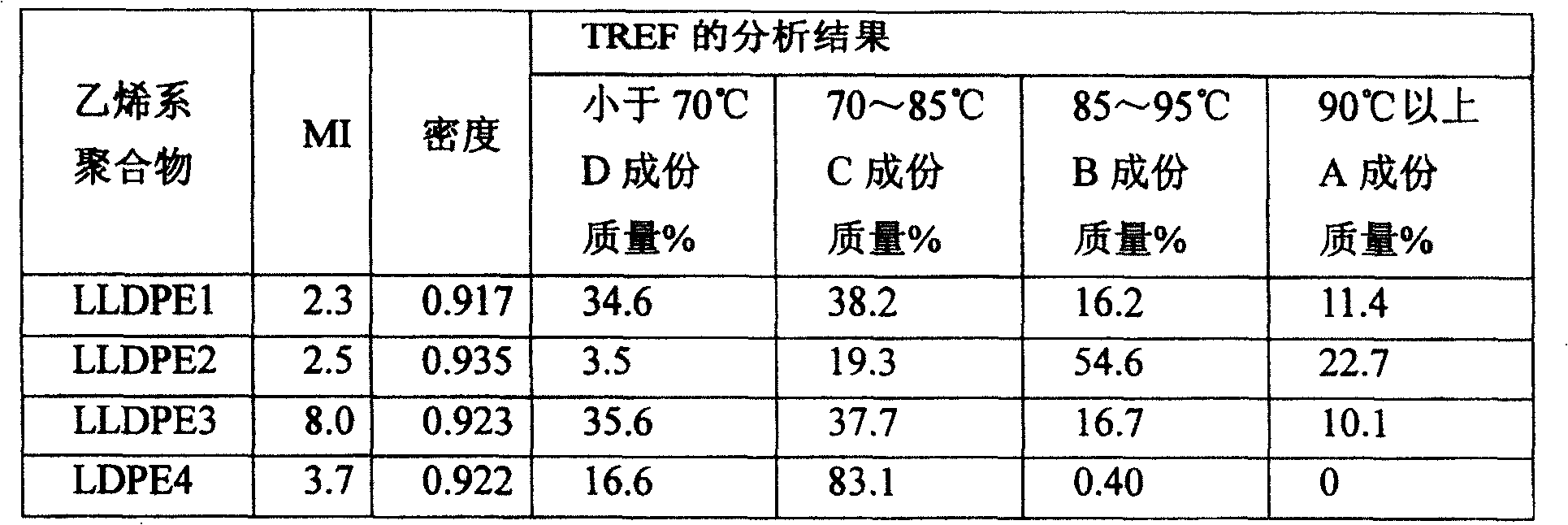

[0079] 30% by mass of linear low density polyethylene 1 (LLDPE1, manufactured by Dow Chemical, trade name "2047G") shown in Table 1, linear low density polyethylene 2 (LLDPE2, manufactured by Dow Chemical, trade name "2036P") 15 % by mass, 5% by mass of branched low-density polyethylene 4 (LDPE4, manufactured by Mitsui Chemicals, trade name "MIRASON16P"), and 50% by mass of calcium carbonate with an average particle diameter of 2.0 μm and zinc stearate as a dispersant, 2 parts by weight relative to the total 100 parts by weight of the above-mentioned vinyl polymer and calcium carbonate were mixed with a super mixer, and then uniformly kneaded at 220°C using a twin-screw kneading extruder and processed into pellets. Using a T-die forming machine, the pellets were formed into a film according to the conditions of the above-mentioned 5) Evaluation method of high-speed stretching film forming property, and a porous film was obtained. Table 2 shows various properties of the obtaine...

Embodiment 2

[0081] Except that the mixing ratio in Example 1 is changed to: LLDPE1 is 20% by mass, LLDPE2 is 15% by mass, LDPE4 is 5% by mass, and calcium carbonate with an average particle diameter of 2.0 μm is 60% by mass, in the same manner as in Example 1 The film was formed under the conditions to obtain a porous film. Table 2 shows various properties of the obtained porous film. Furthermore, the composition of Example 2 did not cause variation in the thickness of the obtained porous film even when the take-up speed of the take-up cooling roll was 60 m / min.

Embodiment 3

[0083] Except that LLDPE2 is 25% by mass, linear low-density polyethylene 3 (LLDPE3, manufactured by Dow Chemical, 2035G) shown in Table 1 is 20% by mass, LDPE4 is 5% by mass, and no dispersant is used. A membrane was formed under the same conditions to obtain a porous thin film. Table 2 shows various properties of the obtained porous film. Furthermore, the composition of Example 3 did not cause variation in the thickness of the obtained porous film even when the take-up speed of the take-up cooling roll was 60 m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com