Parallelogram connecting-rod pressing-wheel film feeding mechanism of vertical quantitative filling packer

A parallelogram and packaging machine technology, applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of wasting production costs, unstable pulling film, and cumbersome adjustment process, etc., to simplify the pressure wheel mechanism and control the adjustment range simple and feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

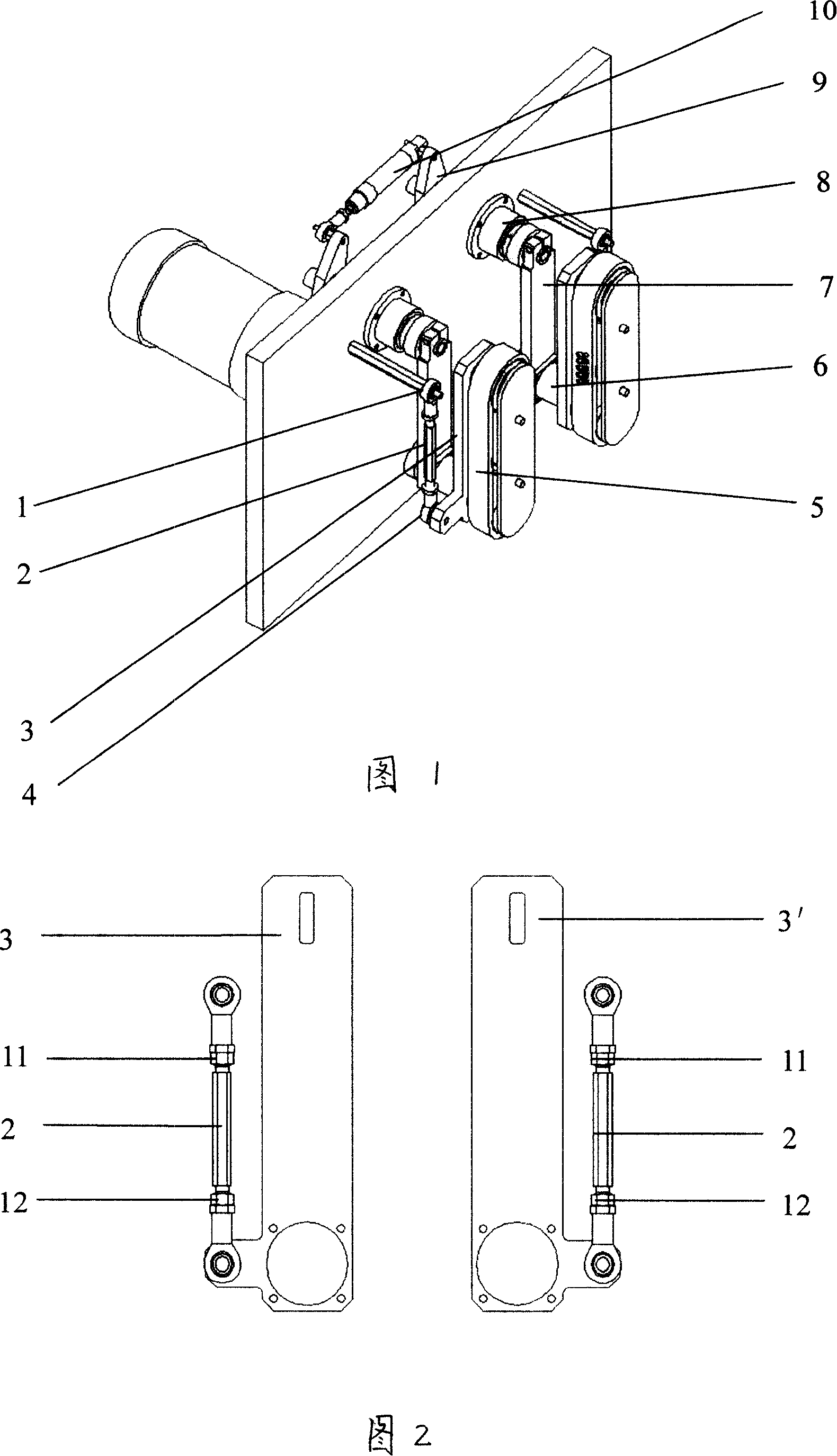

[0014] In Fig. 1, a kind of vertical quantitative filling and packaging machine parallelogram connecting rod pinch wheel conveys roll film mechanism, comprises traction belt 5, bearing seat one 6, swing arm 9 and cylinder 10, described conveying roll film mechanism consists of a Driven by a motor, it is decomposed into two shafts through the synchronous wheel. The synchronous wheel is fixed on the frame. The swing arm 7 drives the swing arm 9 to rotate with the cylinder 10, and the swing arm 9 drives the swing bar 7 to swing left and right, so that the left and right synchronous wheel fixed plate 3, 3' close in the middle, swing arm 9, bearing seat (two) 8 and fulcrum (one) 1, fulcrum (two) 4, connecting rod 2, synchronous wheel fixed plate 3 form two completely symmetrical planar quadrilateral mechanisms, Connecting rod 2 is fixed on the front panel by fulcrum (one) 1, and fulcrum (two) 4 links to each other with synchronous wheel fixed plate 3.

[0015] The parallelogram mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com