Method for preparing lanthanum or cerium pillared montmorillonite fluorine removal agent

A technology for pillared montmorillonite and montmorillonite, which is applied in the field of preparation of fluorine removal agents, can solve the problems of unsatisfactory fluorine removal effect, low adsorption capacity, complicated preparation process, etc., and achieves fast adsorption speed and simple preparation process. , the effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 10g montmorillonite and 0.4gNa 2 CO 3 Put it into a beaker, add 200ml of water to form a suspension with a mass ratio of 5wt%, and stir at a high speed for 90 minutes to obtain a montmorillonite suspension B;

[0033] With 1.0mol / LNaOH 10mL and 100mL 0.1mol / L La(NO 3 ) 3 The solutions are mixed such that OH - with La 3+ The molar ratio is 1, stirred for 30min, and aged for 24h to make lanthanum pillar solution A;

[0034] In the case of high-speed stirring, drop the above-mentioned lanthanum pillar solution A into the sodium montmorillonite suspension B, after the dropwise addition, continue to stir for 1.5h, and age at room temperature for 24h;

[0035] The mixed solution was centrifuged and washed 3 times, and the precipitate was directly placed in a crucible, and baked at 105°C for 16 hours to obtain a lanthanum pillared montmorillonite solid, which was calcined in a muffle furnace at 200°C for 2 hours, Crush and sieve to obtain granular material with a p...

Embodiment 2

[0040] Weigh 10g montmorillonite and 0.4gNa 2 CO 3 Put it into a beaker, add 200ml of water to form a suspension with a mass ratio of 5wt%, and stir at a high speed for 90 minutes to obtain a montmorillonite suspension B;

[0041] With 1.0mol / LNaOH 10mL and 100mL 0.1mol / L Ce(NO 3 ) 3 The solutions are mixed such that OH - with Ce 3+ The molar ratio is 1, stirred for 30min, and aged for 24h to make cerium pillar solution A;

[0042] In the case of high-speed stirring, drop the above-mentioned cerium pillar solution A into the sodium montmorillonite suspension B, after the dropwise addition, continue to stir for 1.5h, and age at room temperature for 24h;

[0043]The mixed solution was centrifuged and washed 3 times, and the precipitate was directly placed in a crucible, and baked at 105°C for 16 hours to obtain a cerium pillared montmorillonite solid, which was calcined in a muffle furnace at 200°C for 2 hours, Crush and sieve to obtain granular material with a particle si...

Embodiment 3

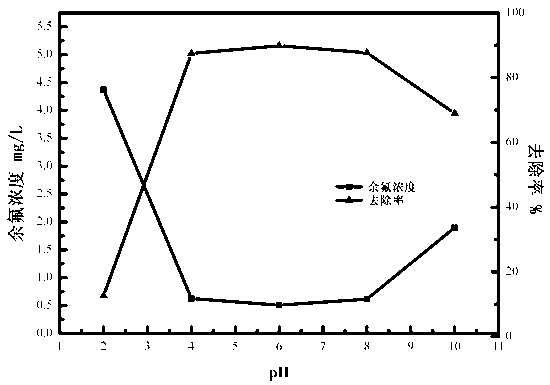

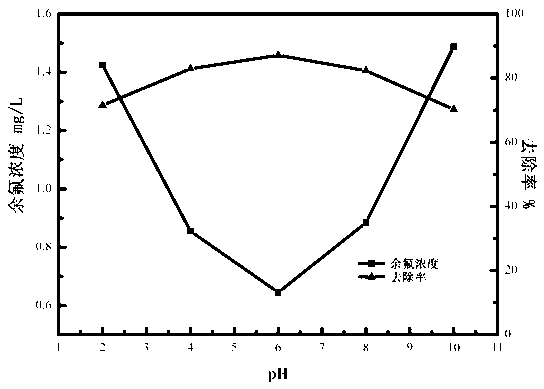

[0048] The preparation of the adsorbent is the same as in Example 1. Weigh 0.1 g of lanthanum pillared montmorillonite defluorination agent and put it into a 250 mL conical flask, add 150 mL of 150 mL of fluorine-containing 5 mg / L aqueous solution, do 3 parallel samples, and use HCl Or adjust the pH of the fluorine solution to 2, 4, 6, 8, and 10 with NaOH, make 3 parallel samples for each pH, and oscillate in a constant temperature oscillator at 25°C for 2 hours at a speed of 160r / min. Take the supernatant and filter (0.45 μm microporous membrane), measure the content of F-, the results are shown in Table 1. It can be seen from Table 1 that when the pH is between 4 and 8, the adsorption effect of the lanthanum pillared montmorillonite defluoridation agent is better, and the fluorine concentration in the effluent has reached the domestic drinking water standard, and it is stable in a wide pH range. The good adsorption effect makes the lanthanum pillared montmorillonite defluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com