Wastewater treatment agent and preparation method thereof

A technology of wastewater treatment agent, aluminum sulfate octadecahydrate, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of poor sewage treatment effect and achieve purification difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

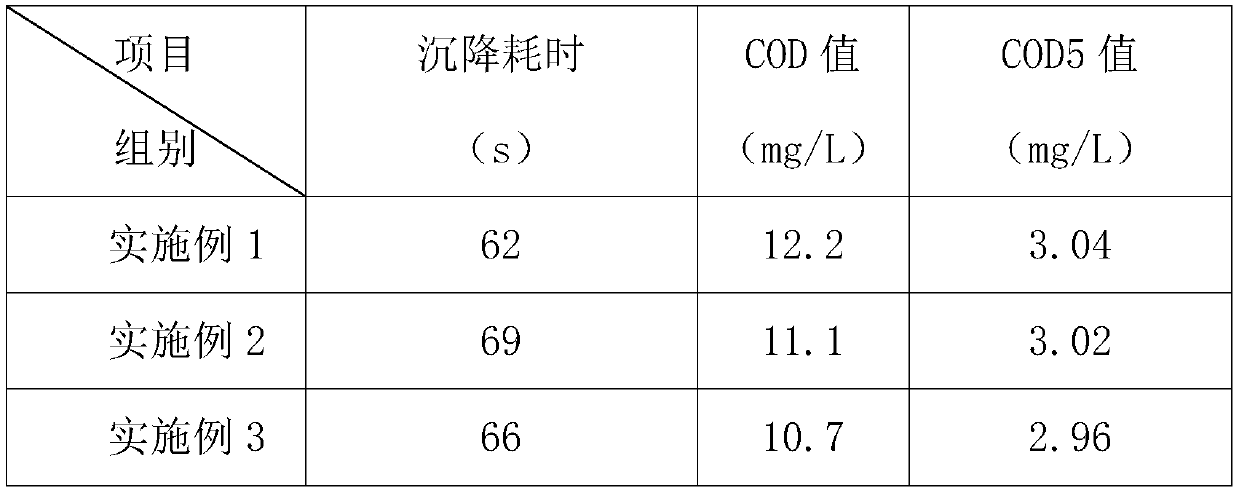

Examples

Embodiment 1

[0033] A wastewater treatment agent, comprising the following raw materials in parts by weight: 120 parts of aluminum sulfate octadecahydrate, 30 parts of polyacrylamide, 60 parts of sodium chloride, 120 parts of calcium carbonate, 64 parts of bentonite, 15 parts of gallic acid, 20 parts of chitosan quaternary ammonium salt, 7 parts of glutathione, 10 parts of sodium pyrophosphate, 7 parts of basic calcium phosphate, 30 parts of activated clay, 3 parts of disodium edetate, 10 parts of sodium polyacrylate, 4 parts of sodium carboxymethylcellulose and 7 parts of sodium diacetate.

[0034] A kind of preparation method of waste water treatment agent comprises the following steps:

[0035] 1) Pour 30 parts of activated clay and 64 parts of bentonite into a grinder together for grinding to ensure that activated clay and bentonite are not agglomerated to obtain a mixed powder;

[0036] 2) 120 parts of aluminum sulfate octadecahydrate, 30 parts of polyacrylamide, 60 parts of sodium c...

Embodiment 2

[0038] A wastewater treatment agent, comprising the following raw materials in parts by weight: 130 parts of aluminum sulfate octadecahydrate, 40 parts of polyacrylamide, 70 parts of sodium chloride, 130 parts of calcium carbonate, 66 parts of bentonite, 20 parts of gallic acid, 25 parts of chitosan quaternary ammonium salt, 18 parts of glutathione, 25 parts of sodium pyrophosphate, 14 parts of basic calcium phosphate, 40 parts of activated clay, 10 parts of disodium edetate, 12 parts of sodium polyacrylate, 6 parts of sodium carboxymethylcellulose and 10 parts of sodium diacetate.

[0039] A preparation method for waste water treatment agent, comprising the following steps:

[0040] 1) Pour 40 parts of activated clay and 66 parts of bentonite into a grinder together for grinding to ensure that activated clay and bentonite are not agglomerated to obtain a mixed powder;

[0041] 2) 130 parts of aluminum sulfate octadecahydrate, 40 parts of polyacrylamide, 70 parts of sodium ch...

Embodiment 3

[0043]A wastewater treatment agent, comprising the following raw materials in parts by weight: 125 parts of aluminum sulfate octadecahydrate, 35 parts of polyacrylamide, 65 parts of sodium chloride, 125 parts of calcium carbonate, 65 parts of bentonite, 18 parts of gallic acid, 24 parts of chitosan quaternary ammonium salt, 13 parts of glutathione, 20 parts of sodium pyrophosphate, 10 parts of basic calcium phosphate, 35 parts of activated clay, 8 parts of disodium edetate, 11 parts of sodium polyacrylate, 5 parts of sodium carboxymethylcellulose and 9 parts of sodium diacetate.

[0044] A preparation method for waste water treatment agent, comprising the following steps:

[0045] 1) 35 parts of activated clay and 65 parts of bentonite are poured into a grinder together for grinding to ensure that activated clay and bentonite are not agglomerated to obtain a mixed powder;

[0046] 2) 125 parts of aluminum sulfate octadecahydrate, 35 parts of polyacrylamide, 65 parts of sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com