High-fluoride-containing wastewater treatment technology in fluorine chemical industry

A technology for wastewater treatment and chemical industry, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc. It can solve the problems of difficult separation and regeneration of adsorbents, small specific gravity, and high moisture content of sludge. , to achieve the effect of fast adsorption and desorption rates, mild regeneration conditions and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

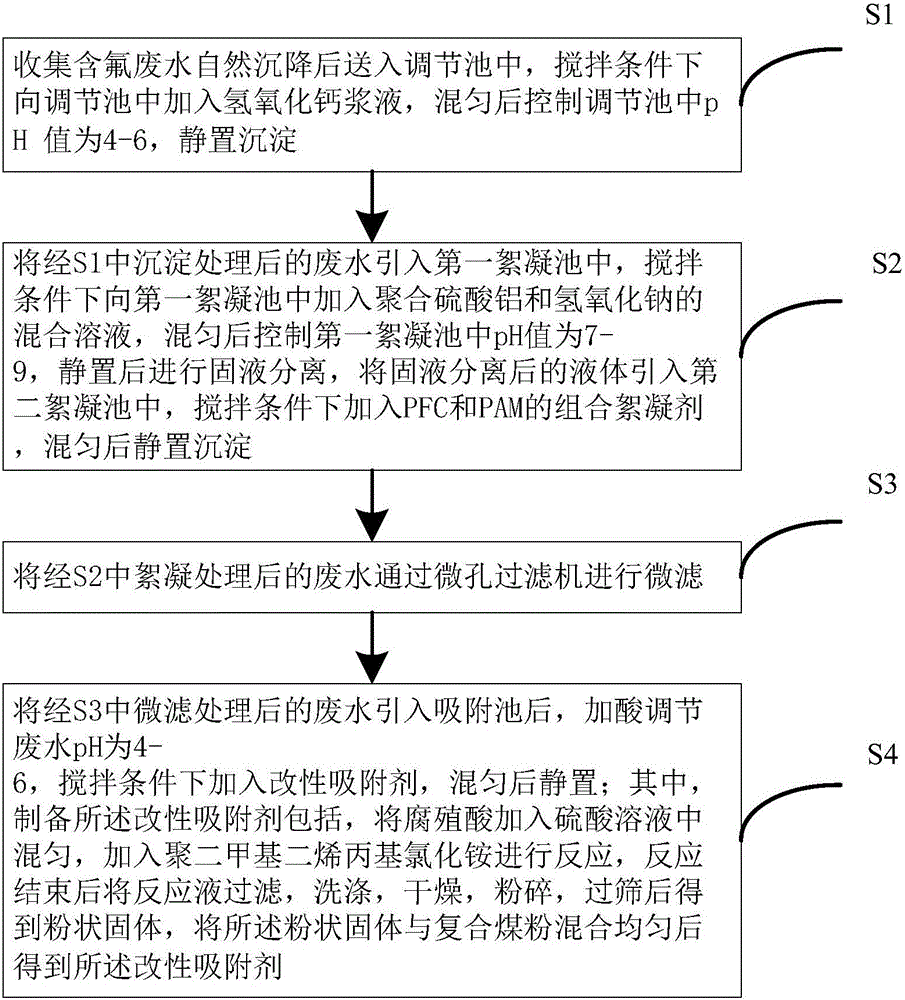

[0034] A kind of high fluorine-containing wastewater treatment process of fluorine chemical industry proposed in this embodiment comprises the following steps:

[0035] S1. Sedimentation: collect fluorine-containing wastewater and settle naturally for 5 hours, then send it to the regulating tank, add calcium hydroxide slurry with a concentration of 15wt% to the regulating tank at a rate of 1.5m / min under stirring conditions, and control the regulating tank after mixing The pH value is 4-5, and it is left to settle for 8 hours;

[0036] S2. Flocculation: introduce the wastewater treated by precipitation in S1 into the first flocculation tank, and add polyaluminum sulfate and hydrogen in a weight ratio of 4:1 to the first flocculation tank at a rate of 0.1 m / min under stirring conditions The mixed solution of sodium oxide, after mixing, control the pH value in the first flocculation tank to 7-8, and carry out solid-liquid separation after standing for 1 hour, introduce the liqui...

Embodiment 2

[0040] A kind of high fluorine-containing wastewater treatment process of fluorine chemical industry proposed in this embodiment comprises the following steps:

[0041] S1. Sedimentation: Collect fluorine-containing waste water to settle naturally for 8 hours and then send it to the regulating tank. Add calcium hydroxide slurry with a concentration of 20wt% to the regulating tank at a rate of 0.5m / min under stirring conditions, and control it in the regulating tank after mixing. The pH value is 5-6, and it is left to settle for 6 hours;

[0042] S2. Flocculation: introduce the wastewater treated by precipitation in S1 into the first flocculation tank, and add polyaluminum sulfate and hydrogen in a weight ratio of 1:1 to the first flocculation tank at a rate of 0.5 m / min under stirring conditions A mixed solution of sodium oxide, after mixing, control the pH value in the first flocculation tank to 8-9, and carry out solid-liquid separation after standing for 3 hours, introduce ...

Embodiment 3

[0046] A kind of high fluorine-containing wastewater treatment process of fluorine chemical industry proposed in this embodiment comprises the following steps:

[0047] S1. Sedimentation: Collect fluorine-containing waste water to settle naturally for 6 hours and send it to the regulating tank. Add calcium hydroxide slurry with a concentration of 17wt% to the regulating tank at a rate of 1.2m / min under stirring conditions, and control the regulating tank after mixing. The pH value is 5-6, and it is left to settle for 7 hours;

[0048] S2. Flocculation: introduce the wastewater treated by precipitation in S1 into the first flocculation tank, and add polyaluminum sulfate and hydrogen with a weight ratio of 3:1 to the first flocculation tank at a rate of 0.3 m / min under stirring conditions The mixed solution of sodium oxide, after mixing, control the pH value in the first flocculation tank to 8-9, and carry out solid-liquid separation after standing for 2 hours, introduce the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com