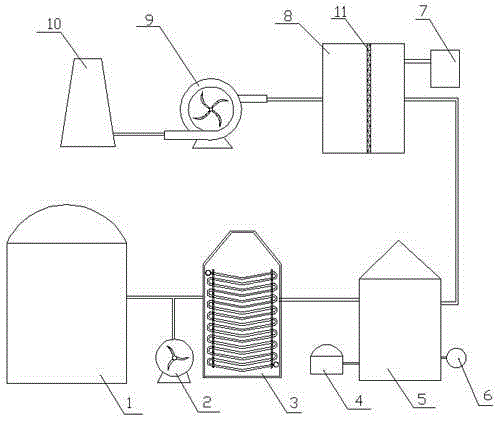

Treatment apparatus and method of high-boron high-fluoride flue gas for glass melting furnaces

A glass melting furnace and flue gas treatment technology, which is applied in the direction of waste heat treatment, energy efficiency improvement, process efficiency improvement, etc., can solve the problems of energy waste, environmental pollution, etc., and achieve the effects of cost-effectiveness, energy saving, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0051] Scale The annual output of pharmaceutical glass tubes is 50,000 tons, which consists of two oxygen-enriched combustion glass melting furnace production lines, and a single production line can produce 70 tons of glass solution per day. Coke oven flue gas (or natural gas) is used as fuel, and the gas consumption is 600 m 3 / h, the supporting gas is high-purity oxygen, 92% oxygen and 7% argon, and the oxygen excess coefficient is 1.2. Flue gas volume at glass melting furnace outlet: 2250Nm 3 / h; flue gas outlet temperature: 1200~1300°C; dust repose angle: dynamic repose angle 45°, static repose angle 60°; flue gas dust concentration: dust 1.4—1.7g / Nm 3 ;B 2 o 3 : 0.6—0.8g / Nm 3 ; Flue gas humidity (volume ratio): 55%.

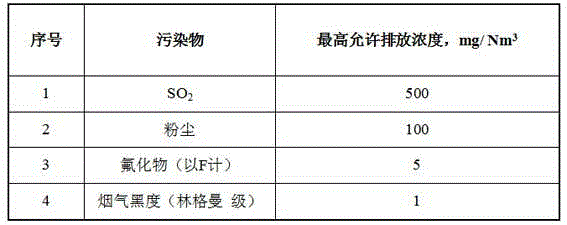

[0052] Table 1 Composition of flue gas from oxy-fuel glass kiln (unit: %)

[0053]

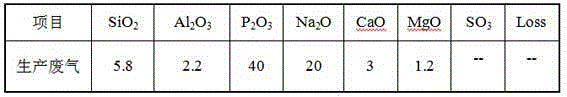

[0054] Table 2 Composition of particles in flue gas of oxy-fuel glass kiln (unit: %)

[0055]

[0056] The energy consumption is as follows: the daily consumpti...

Embodiment approach 1

[0058] Embodiment 1: Power generation with waste heat from flue gas from a glass melting furnace. The flue gas from the glass melting furnace enters the waste heat boiler, and the flue gas from the exit of the waste heat boiler enters the reactor. The waste heat power generation system includes two waste heat boilers and a set of condensing steam turbine generator sets. The installed capacity of the steam turbine is 0.5MW. The waste heat boiler produces saturated steam at 1.40MPa-320℃. Matching with the waste heat exchanger, a condensing steam turbine generator set is set. Heat pipe waste heat boiler inlet exhaust gas parameters: 3500Nm3 / h-900℃, inlet exhaust gas dust concentration <100g / Nm3, outlet exhaust gas temperature ≥300℃, water supply parameters 2t / h-45℃, superheated steam output 1t / h, P= 1.4MPa-320℃, the total air leakage of the boiler is ≤1%, and the layout is in the open air. The rated power of the condensing steam turbine is 0.5MW, and the rated speed is 3000r / m...

Embodiment approach 2

[0062] Embodiment 2: Hot water or heating is provided by waste heat of flue gas from a glass melting furnace. The flue gas from the glass melting furnace enters the waste heat boiler, and the flue gas from the exit of the waste heat boiler enters the reactor. The waste heat hot water and heating system includes 2 waste heat boilers and 2 sets of chemical water production facilities, with a water production capacity of 0.3t / h, and a comprehensive water purification device with a water production capacity of 12t / h. Through the waste heat hot water or heating system, the energy utilization rate is increased by 18%, and the comprehensive energy consumption of the enterprise is reduced.

[0063] The waste heat boiler is connected to the reactor by a round steel air duct. The average particle size is preferably 20~50μm, and the calcium powder prepared in proportion is stored in the calcium powder bin. After being pressurized by the single bin pump, it is fully mixed with the flue g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com