Rapid sedimentation defluorination agent for treating steel-making fluorine-containing turbid circulating water and preparation and use method

A technology of turbid ring water and defluorinating agent, which is applied in the field of water treatment, can solve the problems of high fluoride ion content, and achieve the effect of simple process, strong operability and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

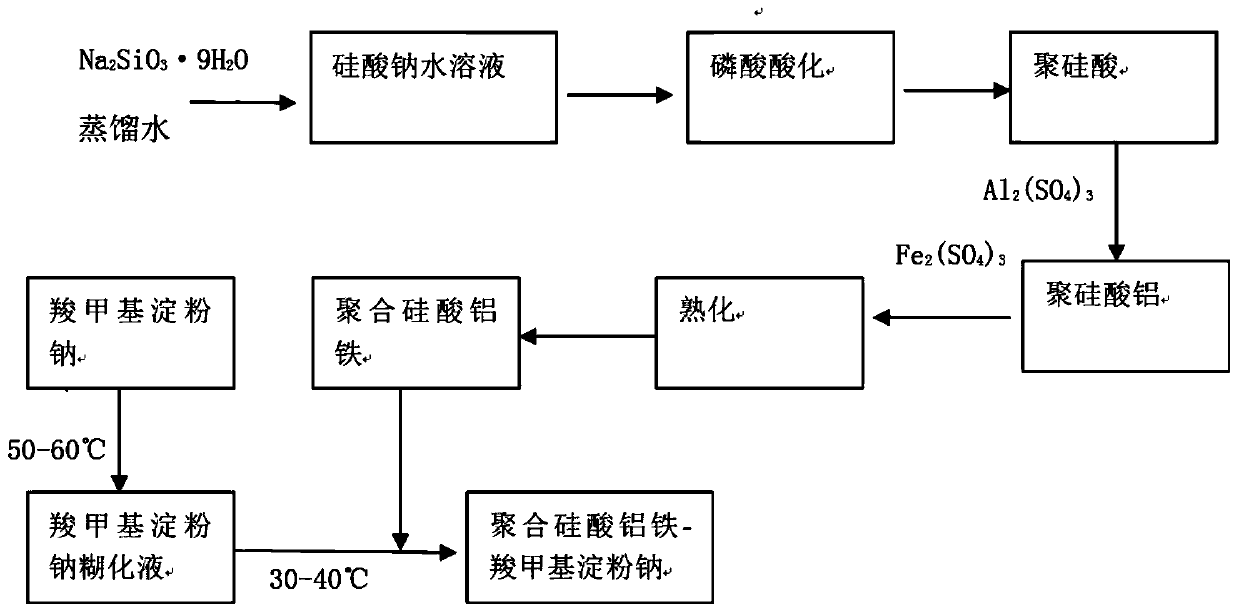

[0043] See figure 1 , the preparation method of the rapid sedimentation defluorination agent of processing fluorine-containing turbid ring water in steelmaking, the preparation method of polymerized aluminum iron silicate-carboxymethyl starch sodium in the described rapid adsorption sedimentation agent comprises the following steps:

[0044] 1) Prepare 0.15-0.25mol / L sodium silicate aqueous solution, take 3-6 parts of sodium silicate aqueous solution and use phosphoric acid with a mass concentration of 10%-15% to adjust the pH to 1.8-2.5, stir at 30-40°C for 2 -3 hours, after standing and aging for 24 hours to obtain polysilicate; then add 0.3-0.45mol / L Al 2 (SO 4 ) 3 2-4 parts of aqueous solution and 0.15-0.3mol / L Fe 2 (SO 4 ) 3 0.5-2 parts of aqueous solution, making n Al:Fe=3:1, n(Al+Fe):SiO 2 =1:1 (n is the ratio of the amount of substances), stir evenly, and obtain polyaluminum iron silicate after aging for 2-4 hours;

[0045] 2) After gelatinizing sodium carboxyme...

Embodiment 1

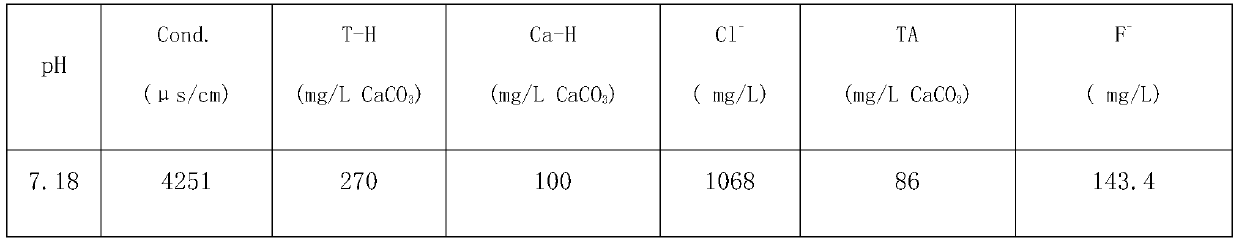

[0067] The test was carried out with a system of water samples from a steelmaking plant. The water quality analysis is shown in Table 2:

[0068] Table 2: Water sample index of embodiment 1

[0069]

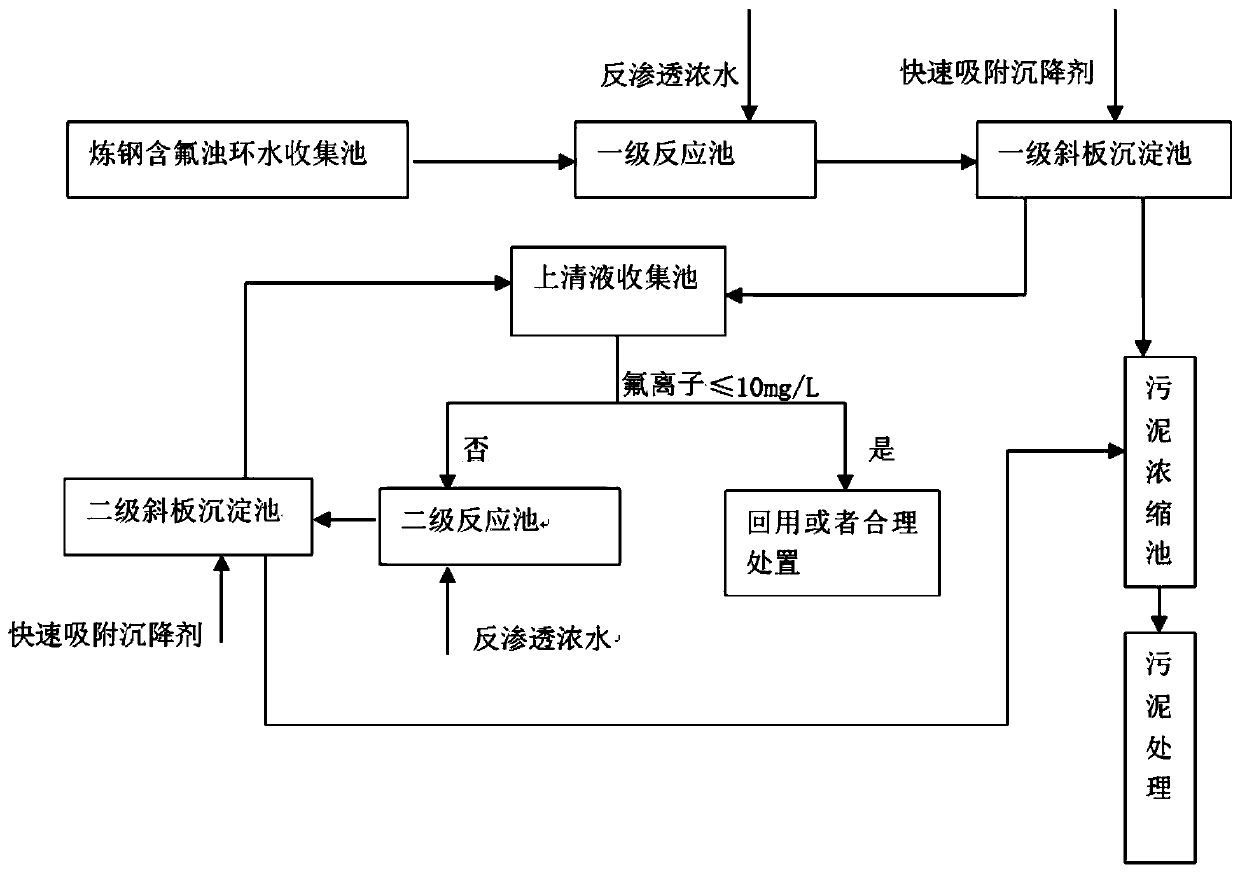

[0070] Implement according to the treatment plan a, subject to the treatment of 1L fluorine-containing water sample, introduce 0.64L of reverse osmosis concentrated water (calcium ion concentration 560mg / L), react for 20-30 minutes and then add a rapid adsorption sedimentation agent at 71.7mg / L, Stir for 10-20 seconds, stand still for 15 minutes, then measure the fluoride ion concentration in the supernatant, which is 9.9 mg / L.

Embodiment 2

[0072] The test was carried out with a system of water samples from a steelmaking plant, and the water quality analysis is shown in Table 3:

[0073] Table 3: Water sample index of embodiment 2

[0074]

[0075] Implement according to the treatment plan b, subject to the treatment of 1L fluorine-containing water sample, introduce 0.15L of reverse osmosis concentrated water (calcium ion concentration 560mg / L), react for 20-30 minutes and then add a rapid adsorption sedimentation agent at 17.3mg / L, Stir for 10-20 seconds, and after standing for 15 minutes, measure the fluoride ion concentration in the supernatant, which is 8.1 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com