Fluoride thin film backplane with light reflection function

A technology of light reflection and light reflection layer, used in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of low production efficiency, easy damage to wafers, no light reflection, etc., to achieve good bonding efficiency, good reflection performance, and improved The effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

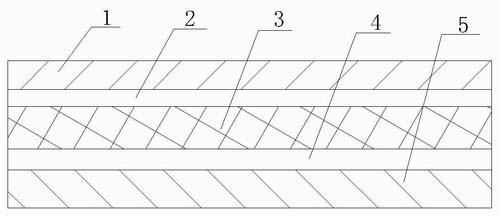

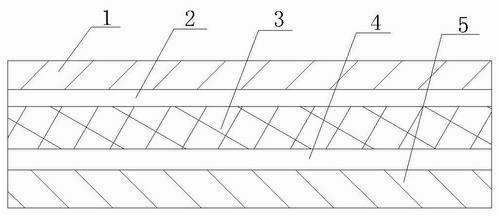

[0022] Such as figure 1 Shown is a fluorine film backboard with light reflection function. The backboard is sequentially provided with a PU casting layer 1, a light reflection layer 2, a PET layer 3, an adhesive layer 4 and a high fluorine alloy from top to bottom. crystal thin film layer 5, the PET layer 3 is connected with the PU casting layer 1 through the light reflection layer 2, the PET layer 3 is connected with the high fluorine alloy crystal thin film layer 5 through the thermal fusion of the adhesive layer 4, and the high The fluorine content in the fluorine crystal thin film layer 5 is 76%, and the thickness of the PU casting layer 1 is 2-3 μm. The PU casting layer 1 of the present invention has a fast bonding time with the battery sheet, front sheet, etc., which is 2-3min. Yes, the shrinkage rate is small.

[0023] The PET layer 3 of the present invention is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com