Environment-friendly water washing resistant waterproof agent and preparation method thereof

A water-repellent and water-resistant technology, which is applied in textiles and papermaking, fiber treatment, and liquid-repellent fibers, etc., can solve the problems of weak water-washing resistance, achieve excellent waterproof effect and water-washing resistance, and stabilize the waterproof layer , Improve the effect of waterproof rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

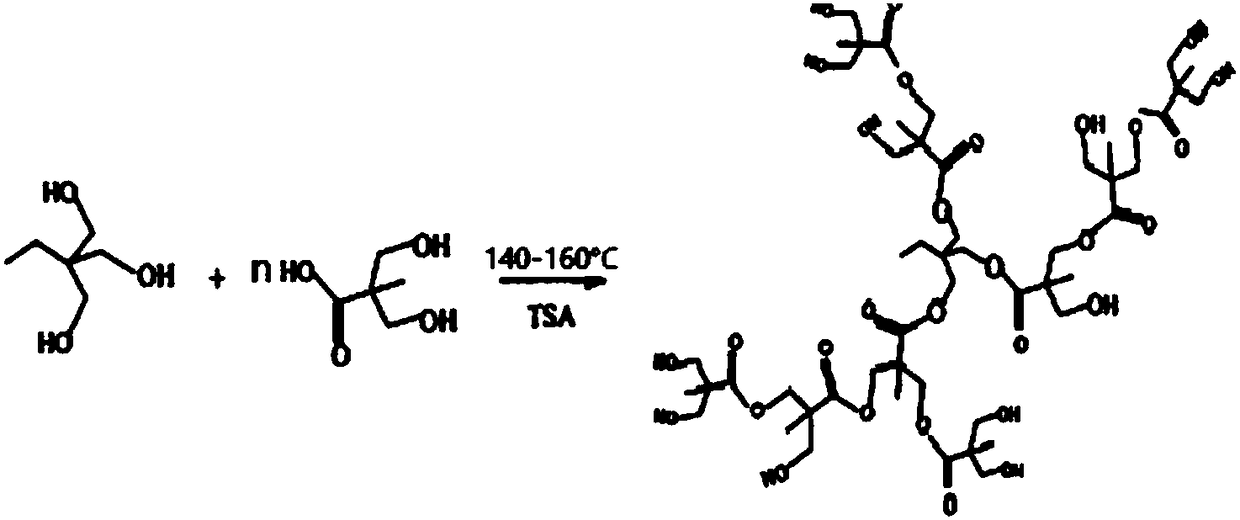

[0032] 1. Mix trimethylolpropane and 2,2-dimethylolpropionic acid at a molar ratio of 1:9, raise the temperature to 140-160°C, and add 0.5-1% catalyst to formaldehyde under the protection of argon. Base benzene sulfonic acid, react for 2-3 hours, reduce the pressure to 400-500Pa, continue the reaction for 2-3 hours, stop reducing the pressure and cool down to 40-60°C, add a certain amount of acetone to dissolve, and then precipitate with ether to obtain the product hyperbranched polyester.

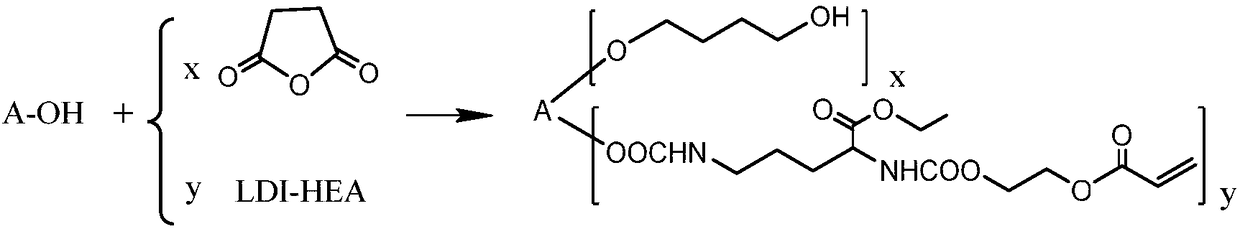

[0033] 2. Mix lysine diisocyanate and hydroxyethyl acrylate in a molar ratio of 1:1, and react at 40-45°C for 10-12 hours to obtain the semi-addition product LDI-HEA.

[0034] 3. Stir and mix the hyperbranched polyester, succinic anhydride and a certain amount of acetone in step 1, react at 90-95°C for 4-5h, cool down to 45-50°C, add LDI-HEA, and continue the reaction for 5- 6h, stop the reaction. The product was precipitated with acetone ether and dried in vacuum to obtain a modified hyp...

Embodiment 2

[0036] 1. Mix trimethylolpropane and 2,2-dimethylolpropionic acid at a molar ratio of 1:9, raise the temperature to 140-160°C, and add 0.5-1% catalyst to formaldehyde under the protection of argon. Base benzene sulfonic acid, react for 2-3 hours, reduce the pressure to 400-500Pa, continue the reaction for 2-3 hours, stop reducing the pressure and cool down to 40-60°C, add a certain amount of acetone to dissolve, and then precipitate with ether to obtain the product hyperbranched polyester.

[0037] 2. Mix lysine diisocyanate and hydroxyethyl acrylate in a molar ratio of 1:1, and react at 40-45°C for 10-12 hours to obtain the semi-addition product LDI-HEA.

[0038] 3. Stir and mix the hyperbranched polyester, succinic anhydride and a certain amount of acetone in step 1, react at 90-95°C for 4-5h, cool down to 45-50°C, add LDI-HEA, and continue the reaction for 5- 6h, stop the reaction. The product was precipitated with acetone ether and dried in vacuum to obtain a modified hyp...

Embodiment 3

[0040] 1. Mix trimethylolpropane and 2,2-dimethylolpropionic acid at a molar ratio of 1:20, raise the temperature to 140-160°C, and add 0.5-1% catalyst to formaldehyde under the protection of argon Base benzene sulfonic acid, react for 2-3 hours, reduce the pressure to 400-500Pa, continue the reaction for 2-3 hours, stop reducing the pressure and cool down to 40-60°C, add a certain amount of acetone to dissolve, and then precipitate with ether to obtain the product hyperbranched polyester.

[0041] 2. Mix lysine diisocyanate and hydroxyethyl acrylate in a molar ratio of 1:1, and react at 40-45°C for 10-12 hours to obtain the semi-addition product LDI-HEA.

[0042] 3. Stir and mix the hyperbranched polyester, succinic anhydride and a certain amount of acetone in step 1, react at 90-95°C for 4-5h, cool down to 45-50°C, add LDI-HEA, and continue the reaction for 5- 6h, stop the reaction. The product was precipitated with acetone ether and dried in vacuum to obtain a modified hyp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com