Preparation method of high-whiteness high-temperature-resistance color masterbatch level titanium dioxide

A technology of high temperature resistance and titanium dioxide, applied in chemical instruments and methods, dyeing physical treatment, dyeing organic silicon compound treatment, etc., can solve the problem of whiteness, dispersibility, hiding power and processing torque of plastic masterbatch system No guarantee, great influence of titanium dioxide inorganic coating, etc., to achieve high yellowing resistance, improved whiteness, and high application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

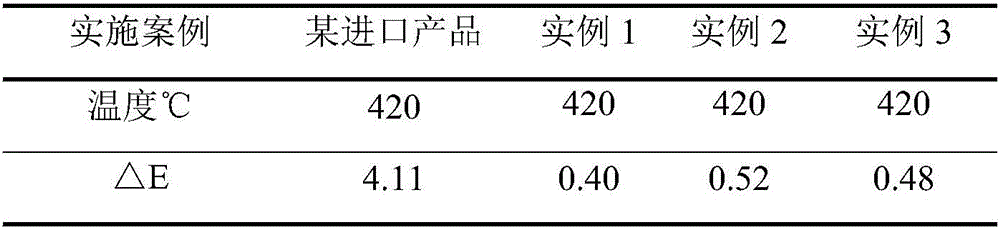

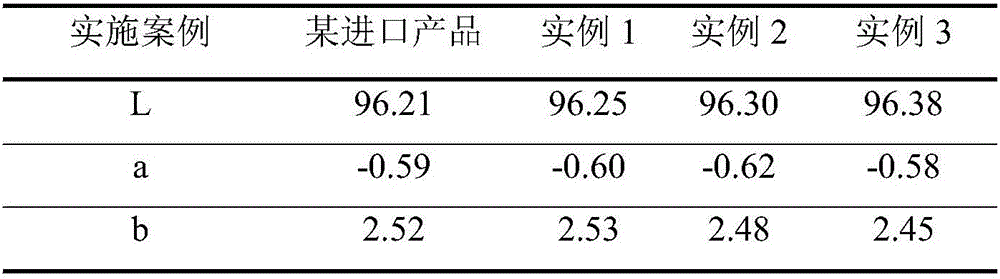

Examples

Embodiment 1

[0028] (1) Wash the metatitanic acid once, add Ti 3+ Bleaching with sulfuric acid, followed by secondary washing, press filtration after washing to obtain a metatitanic acid filter cake with an iron content of less than 10ppm;

[0029] (2) After beating and dispersing the metatitanic acid filter cake to obtain a slurry with a concentration of 300g / L, carry out combined salt treatment with zinc salt, potassium salt and phosphorus salt, and the addition of zinc sulfate, potassium carbonate and phosphoric acid is 0.05% respectively , 0.35%, 0.3% (based on the mass fraction of titanium dioxide, the addition amount is represented by oxide ZnO, K 2 O, P 2 o 5 mass meter), then calcined at 950° C. to obtain the kiln bottoms with a rutile conversion rate of 94%;

[0030] (3) After the calcined rutile kiln bottoms are prepared by adding water and sodium silicate as a dispersant to prepare a 500g / L slurry, it enters a ball mill for coarse grinding, then enters a sand mill for fine gr...

Embodiment 2

[0035] (1) Wash the metatitanic acid once, add Ti 3+ Bleaching with sulfuric acid, followed by secondary washing, press filtration after washing to obtain a metatitanic acid filter cake with an iron content of less than 10ppm;

[0036] (2) After beating and dispersing the metatitanic acid filter cake to obtain a slurry with a concentration of 200g / L, carry out combined salt treatment with zinc salt, potassium salt and phosphorus salt, and the addition of zinc sulfate, potassium carbonate and phosphoric acid is 0.2% respectively , 0.25%, 0.20% (based on the mass fraction of titanium dioxide, the addition amount is represented by oxide ZnO, K 2 O, P 2 o 5 mass meter), then calcined at 950° C. to obtain the kiln bottoms with a rutile conversion rate of 96%;

[0037] (3) After the calcined rutile kiln bottoms are prepared by adding water and sodium silicate as a dispersant to prepare a 300g / L slurry, it enters a ball mill for coarse grinding, then enters a sand mill for fine gr...

Embodiment 3

[0042] (1) Wash the metatitanic acid once, add Ti 3+ Bleaching with sulfuric acid, followed by secondary washing, press filtration after washing to obtain a metatitanic acid filter cake with an iron content of less than 10ppm;

[0043] (2) After beating and dispersing the metatitanic acid filter cake to obtain a slurry with a concentration of 400g / L, carry out combined salt treatment with zinc salt, potassium salt and phosphorus salt, and the addition of zinc sulfate, potassium carbonate and phosphoric acid is 0.15% respectively , 0.45%, 0.4% (based on the mass fraction of titanium dioxide, the addition amount is represented by oxide ZnO, K 2 O, P 2 o 5 mass meter), then calcined at 950° C. to obtain the kiln bottoms with a rutile conversion rate of 98%;

[0044] (3) After the calcined rutile kiln bottoms are prepared by adding water and sodium silicate as a dispersant to prepare a 700g / L slurry, it enters a ball mill for coarse grinding, then enters a sand mill for fine gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com