Roofing Material And Method Of Making The Same

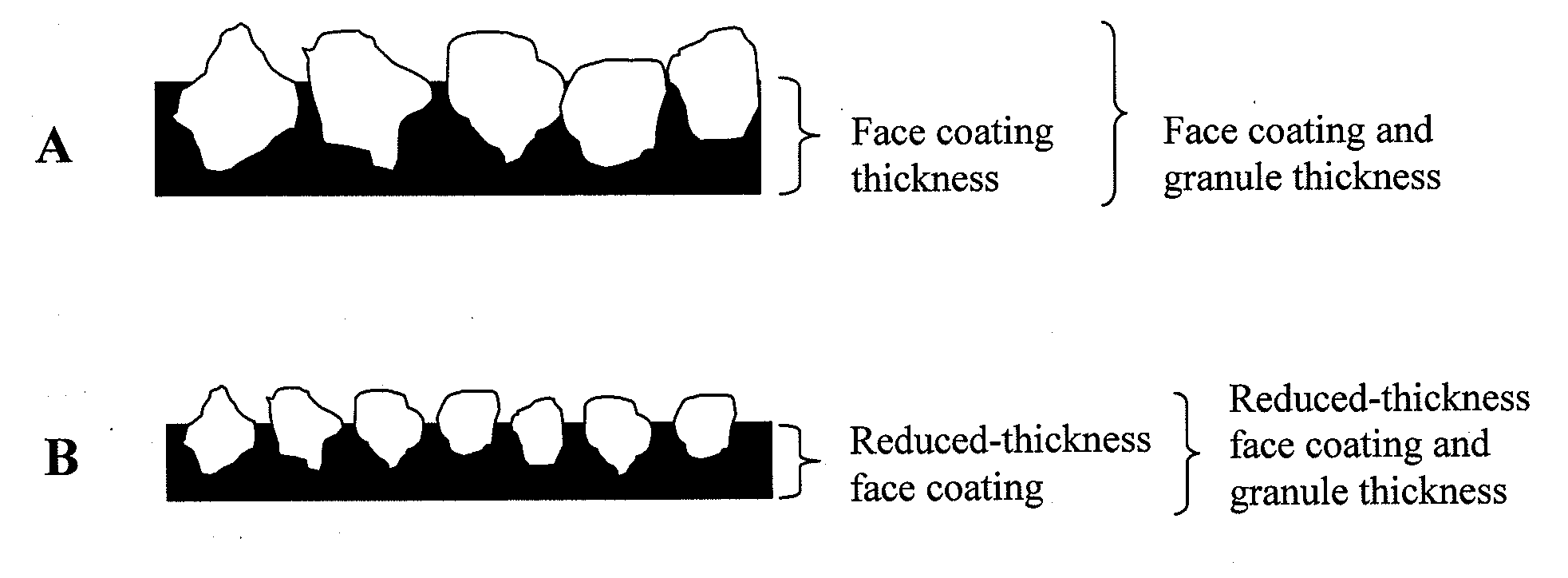

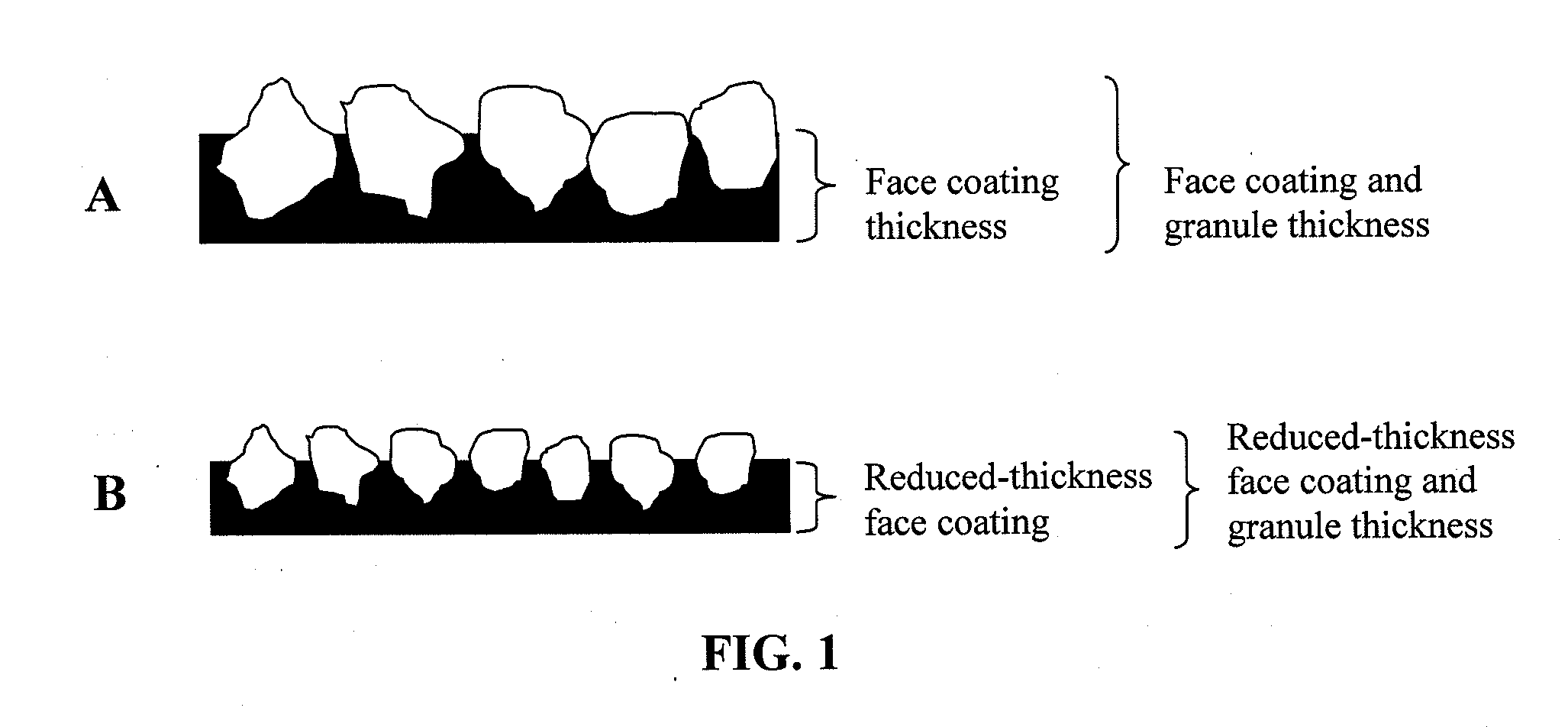

a technology of roofing materials and shingles, applied in the field of roofing materials, can solve the problems of reducing the cost and/or weight of shingles, and difficulty in achieving desired physical characteristics, and achieve the effect of enhancing visual appearance and great depth or thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0027]A fiberglass mat of about 1.63 lbs / csf was placed on a jumbo roll having a width corresponding to the width of the mat. The shingles were made in a continuous process where the glass mat was coated on the upper surface and lower surface with asphalt comprising a limestone filler. Fines were provided on the lower surface to seal the asphalt coating.

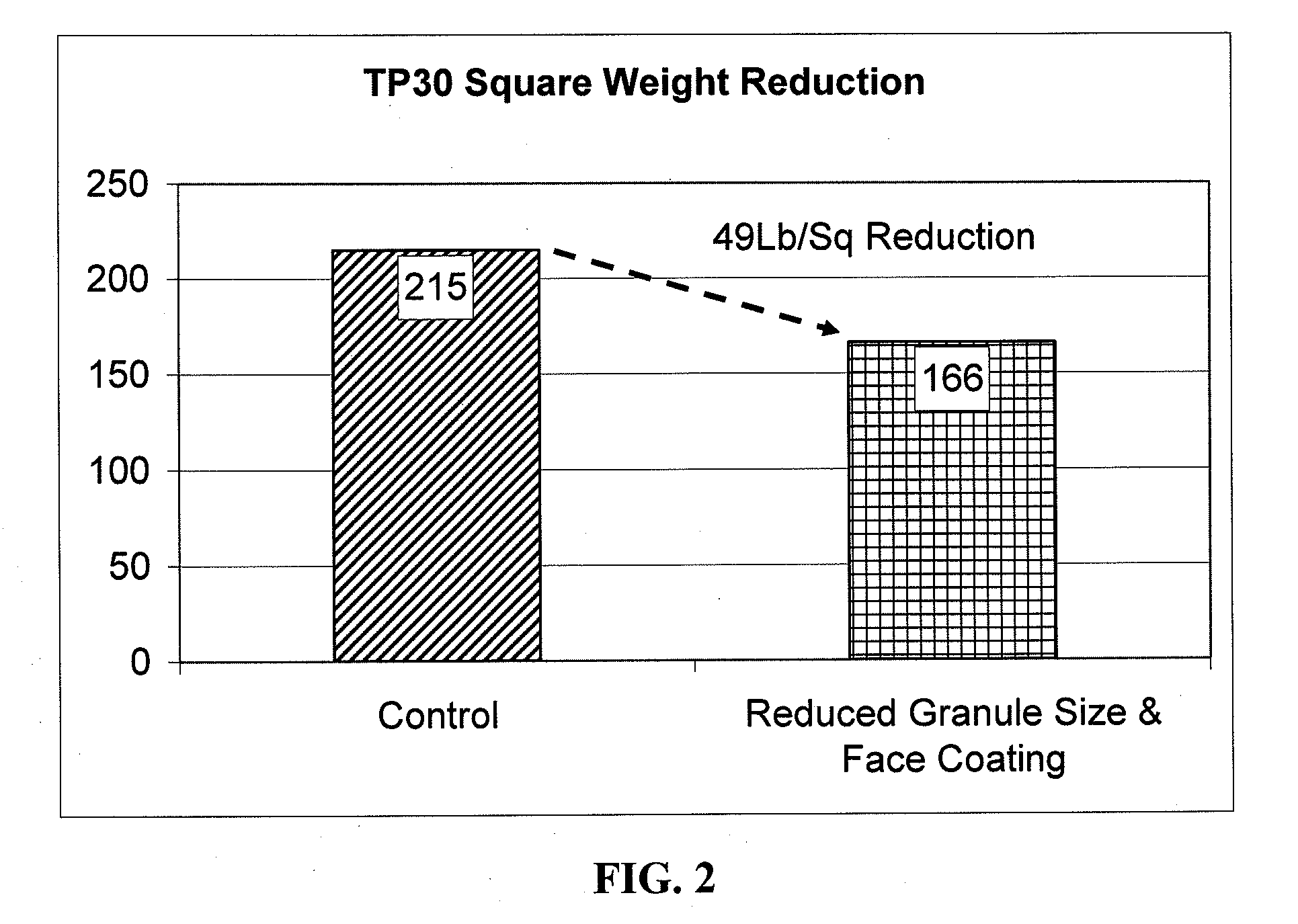

[0028]Table I below compares the weight of the face coat and granule layers for a control shingle and inventive shingle in accordance with the invention. For the inventive shingle, the thickness of the asphalt coating applied to the upper surface, i.e., the face coating, was 14 mils and had a weight of 12 lbs / csf. Grade 18 granules (IPS Mineral Products) having an average particle size of 23 mils were deposed on the face coating in a continuous process. A control shingle was also prepared in which the thickness of the face coating was 20 mils and had a weight of 17.5 lbs / csf. Grade 11 granules having an average particle size of 47 mi...

example 2

[0031]Two granule size distributions (version #1 and version #2) used to prepare the shingles of the present invention were compared with a control granule size distribution (control butt granules) used in conventional roofing shingles. At least 100 squares of both laminated and single layer strip shingles were manufactured using each of the granule size distributions by conventional shingle manufacturing processes. Each shingle was manufactured using the same coating weight or composition to demonstrate the affect of each granule distribution on the physical characteristics of the shingle. The control laminated shingles and the control strip shingles were manufactured by standard techniques using the butt granule size distributions.

[0032]Table IV indicates the retained percentage of granules for each sieve. Table V indicates the bulk density and specific gravity for each granule size distribution.

TABLE IVSievesControlUS meshSieveButtVersion #1Version #2(mils)OpeningGranulesGranules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com