LED packaging structure and LED light source device

A technology of LED packaging and reflective cups, which is applied to the semiconductor devices of light-emitting elements, light sources, light source fixing and other directions, can solve the problems of increased difficulty in operating LED lights, and achieve the effects of reducing friction area, firm cooperation, and convenient adjustment and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

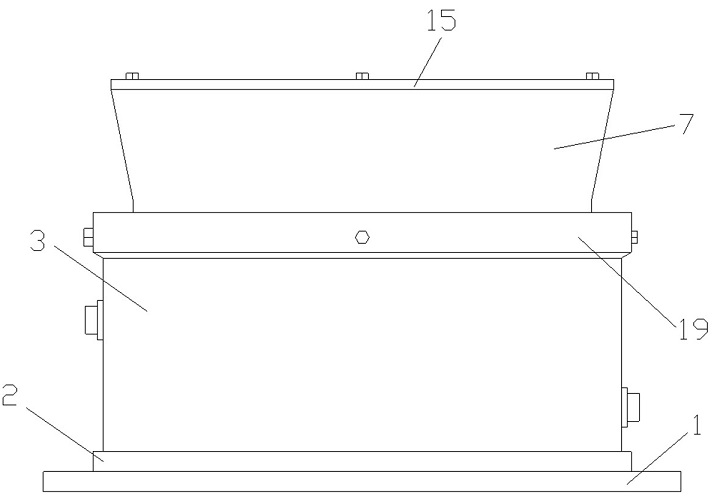

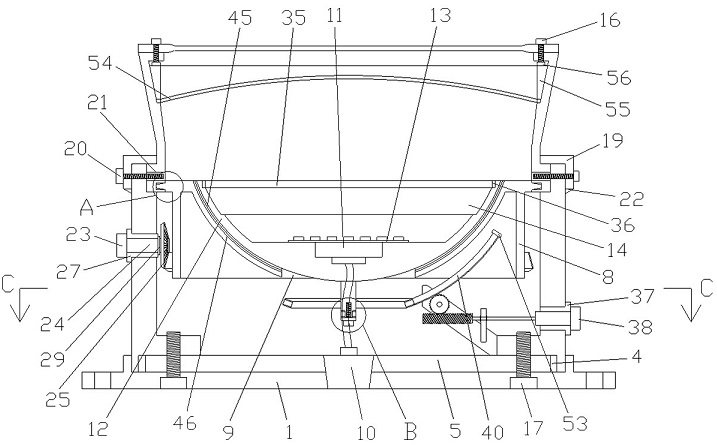

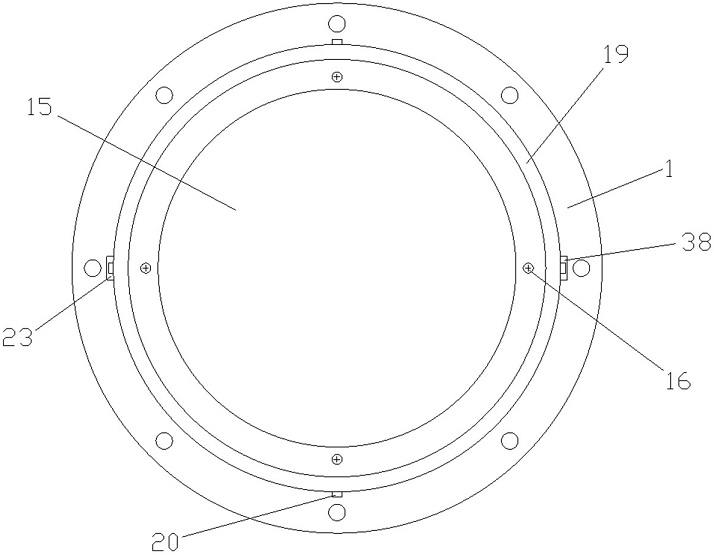

[0030] Such as Figure 1~8 As shown, the present invention provides an LED packaging structure, which includes a base 1, a limiting side 2 is provided on the edge of the surface of the base 1, and a housing 3 is provided on the surface of the base 1 inside the limiting side 2. The inner side of the bottom end of the shell 3 is provided with a first matching groove, the edge of the first matching groove is provided with a first expansion rubber ring 4, and the surface of the base 1 inside the first expansion rubber ring 4 is provided with a heat dissipation substrate 5 , the inner wall of the top of the housing 3 is provided with a second matching groove, the bottom end of the second matching groove is fitted with a gasket block 6, a lampshade 7 is arranged above the gasket block 6, and the gasket block 6 The inner side is provided with an annular third matching groove, and a rotating fixed seat 8 is fitted in the third matching groove, and a rotation control mechanism is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com