Finger type cover grabbing hand

A finger and bottle cap technology, applied in the field of cap grippers, can solve problems such as dislocation of bottle caps, product damage, easy wear or breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

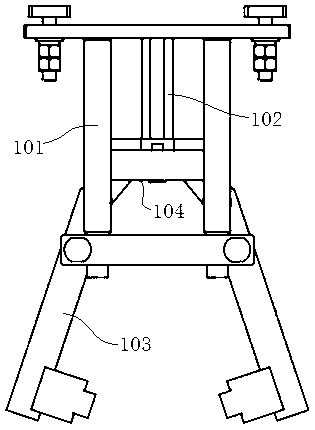

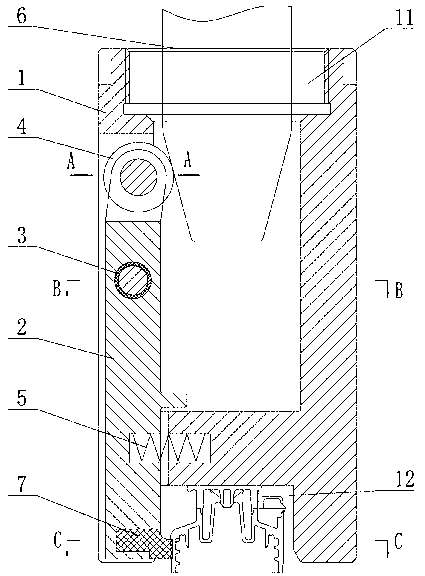

[0013] as the picture shows.

[0014] The finger-type cap gripping hand of the present invention comprises a bracket 1, a cap gripping finger 2, and the cap gripping finger 2 is installed on the bracket 1 through a pin shaft 3, and the pin shaft 3 is arranged at the middle part of the cap gripping finger 2, and the cap gripping finger 2 The upper end of the upper end is connected with a roller 4, the lower end of the cap-grabbing finger is connected to the bracket 1 through a spring 5, the cap-grabbing finger 2 and the bottom of the bracket 1 enclose a groove 12 for the bottle cap to extend into, and the top of the bracket 1 has a through hole 11. There is a driving rod 6 that moves radially along the through hole 11, and the driving rod 6 and the roller 4 are pressed against each other, and the contact surface thereof is an inclined surface; there are three or more fingers 2 for grasping the cover.

[0015] The circumference of the three cover-grabbing fingers 2 is evenly dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com