Frosting liquid medicine and process for directionally arranging crystal lattices on etched surface of high-alumina-silica glass

A directional arrangement, high-alumina-silicon technology, applied in the C03C15/00 field, can solve the problems of easy adhesion of fingerprints, high efficiency of frosting paste, single pattern effect, etc., and achieve high aesthetics, friendly equipment pipelines and circulation systems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

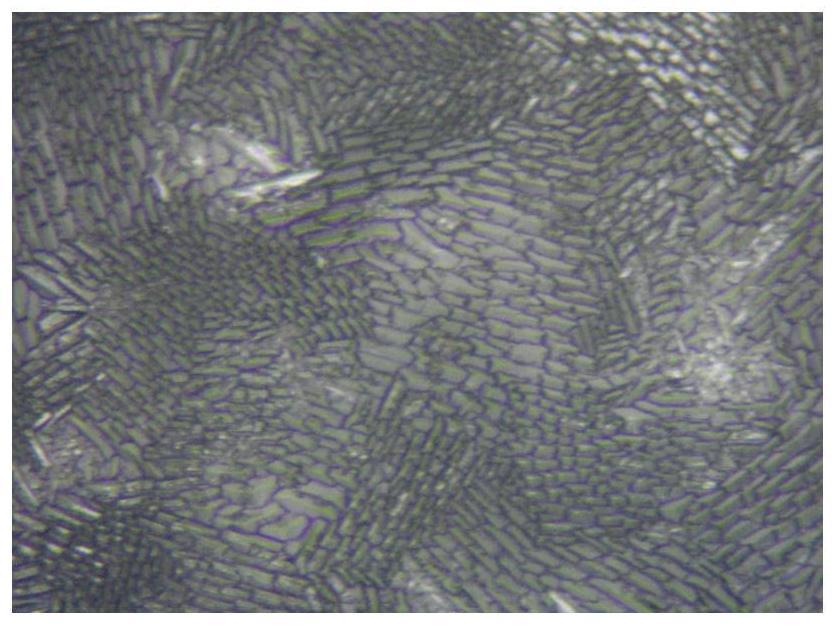

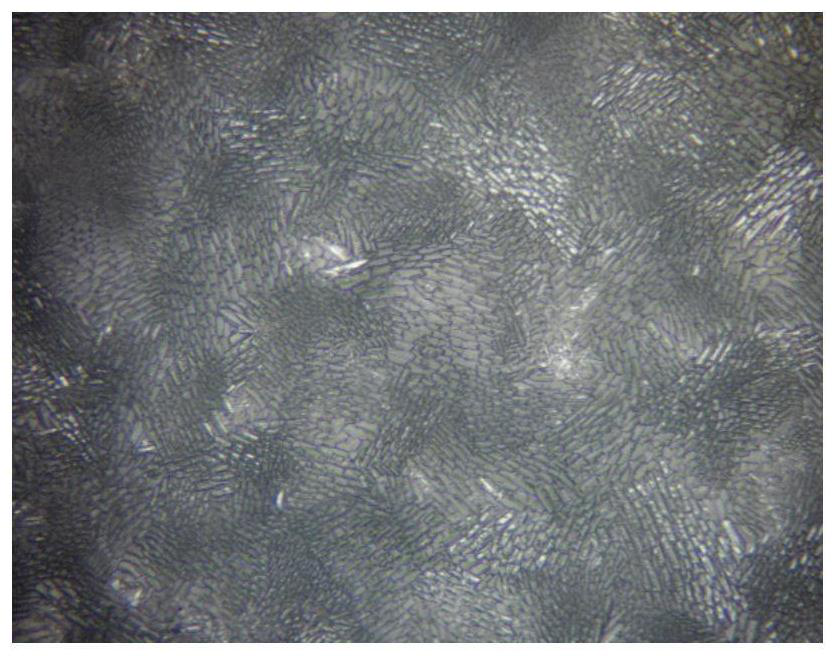

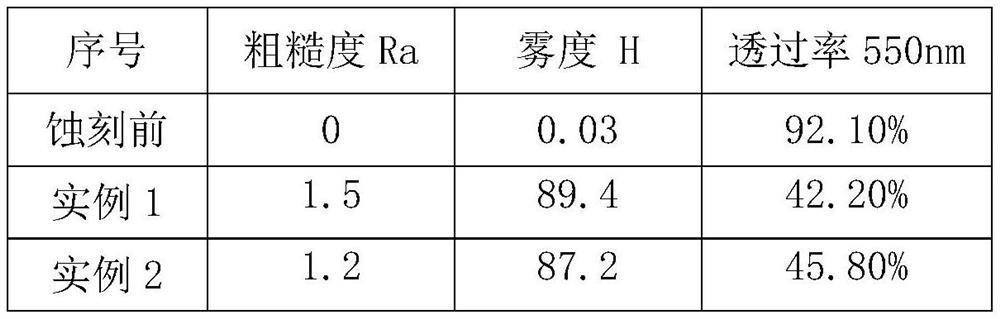

Image

Examples

Embodiment 1

[0045] The first aspect of this embodiment proposes a frosting potion with oriented lattice alignment on the etched surface of high-alumina silica glass. The raw materials for preparation include 8 parts by weight of water, 9.1 parts of fluoride, 2.2 parts of ammonium fluorosilicate, 6.5 parts of inorganic acid salts, 4.5 parts of nitric acid, 1.4 parts of citric acid, 0.5 parts of methylcellulose, and 0.3 parts of sodium vinylsulfonate.

[0046] The fluorides are ammonium bifluoride, sodium fluoride and potassium fluoride in a weight ratio of 5.8:0.8:2.5.

[0047] The inorganic acid salt was ammonium sulfate and potassium nitrate in a weight ratio of 4.5:2.

[0048] The second aspect of this embodiment proposes a frosting process for the alignment of the etched surface of the high-alumina silica glass, which includes the following steps:

[0049] (1) prepare frosting syrup according to the above-mentioned preparation raw materials;

[0050] (2) Ink protection treatment is p...

Embodiment 2- Embodiment 5

[0056] The formula of the frosting syrup of embodiment 2-5 is shown in the following table, and the frosting process of embodiment 2-5 is the same as that of embodiment 1.

[0057] parts by weight Example 2 Example 3 Example 4 Example 5 water 8 8 8 8 Ammonium hydrogen fluoride 5.2 4 3.5 3.2 Potassium Fluoride 0.8 0.8 0.8 0.8 sodium fluoride 2.5 2.5 2.5 2.5 Ammonium Fluorosilicate 2.2 2.2 2.2 2.2 Ammonium sulfate 4.5 4.5 4.5 4.5 Potassium nitrate 2 2 2 2 Nitric acid 4 3.5 3.5 3 citric acid 1.4 1.4 1.4 1.4 Methylcellulose 0.5 0.5 0.5 0.5 Sodium vinyl sulfonate 0.3 0.3 0.3 0.3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com