A kind of preparation method of anti-glare hardened film for polarizer

An anti-glare and hardened film technology, applied in the coating and other directions, can solve the problems of trouble in use, uneven color, and high process requirements, and achieve the effects of simple and efficient preparation method, good anti-glare effect, and high controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

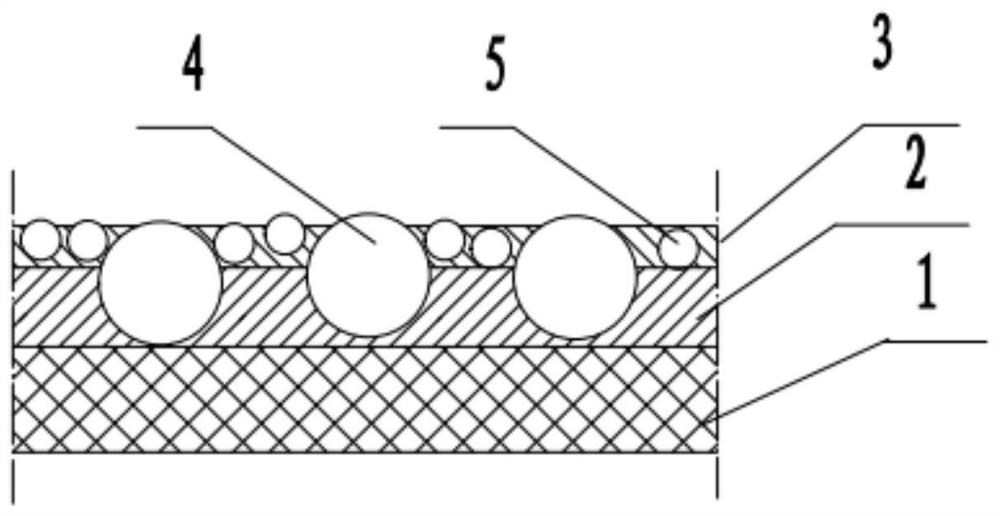

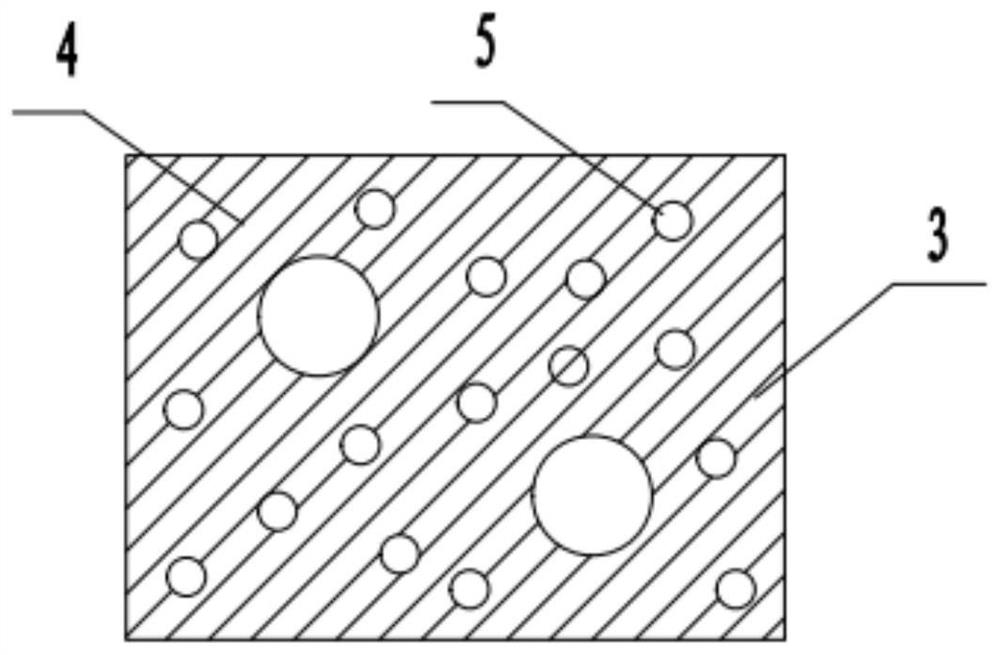

[0033] The preparation of anti-glare hardened film is operated according to the following steps:

[0034] 1. Prepare the first anti-glare layer: coat the coating solution for the first anti-glare layer on the PET of 80 μm, the coating solution for the first anti-glare layer consists of 5g 1,6-hexanediol dimethacrylate ( Sartomer, trade name: SR239NS, functionality: 2), 40g two-trimethylolpropane tetraacrylate (Sartomer, trade name: SR355NS, functionality: 4), 5g photoinitiator (Tianjin Tianjiao Chemical Industry Co., Ltd., trade name: 184), 0.1g leveling aid (TEGO FLOW 370), 0.1g dispersion aid (BYK-111), 1.8g organic particles (Soken Chemical, model MR- 2G, particle size 1μm) and 48g of ethyl acetate; after the first anti-glare layer is coated, it is dried in two-stage ovens, the temperature of the first-stage oven is 30°C, and the temperature of the second-stage oven is 45°C; the first anti-glare layer The coating thickness of the glare layer was 0.8 μm, and the haze of the...

Embodiment 2

[0038] The preparation of anti-glare hardened film is operated according to the following steps:

[0039] 1., prepare the first anti-glare layer: on the TAC of 25 μm, coat the coating liquid for the first anti-glare layer, the coating liquid for the first anti-glare layer is made of 20g neopentyl glycol dimethacrylate (Sartomer , trade name: SR248, functionality: 2), 32g dipentaerythritol pentaacrylate (Sartomer, trade name: SR399, functionality: 5), 0.5g photoinitiator (manufacture by Tianjin Tianjiao Chemical Co., Ltd., trade name: 1173), 5g leveling aid (BYK-315), 0.5g dispersing aid (BYK-2008), 2g organic particles (Soken Chemical, model MX-1500H, particle size 15μm) and 40g acetone Composition: After the first anti-glare layer is coated, it is dried in two-stage ovens, the temperature of the first-stage oven is 40°C, and the temperature of the second-stage oven is 50°C; The haze of the anti-glare layer was 0.5%.

[0040] 2. Prepare the second anti-glare layer: apply the...

Embodiment 3

[0043] The preparation of anti-glare hardened film is operated according to the following steps:

[0044] 1., prepare the first anti-glare layer: on the PMMA of 60 μm, coat the coating solution for the first anti-glare layer, the coating solution for the first anti-glare layer is made of 20g tetraethylene glycol dimethacrylate (sand Dorma, trade name: SR209, functionality: 2), 10g dipentaerythritol hexaacrylate (Changxing Chemical, trade name: EM266, functionality: 4), 4g photoinitiator (manufactured by Tianjin Tianjiao Chemical Co., Ltd., trade name: TPO), 4.5g leveling aid (TEGO FLOW 425), 1g dispersion aid (TEGO Dispers 652), 0.5g organic particles (Soken Chemical, model MR-10HG, particle size 10μm) and 60g Composed of ethyl acetate; after the first anti-glare layer is coated, it is dried in two-stage ovens, the temperature of the first-stage oven is 35°C, and the temperature of the second-stage oven is 40°C; the coating thickness of the first anti-glare layer is 8 μm , the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com