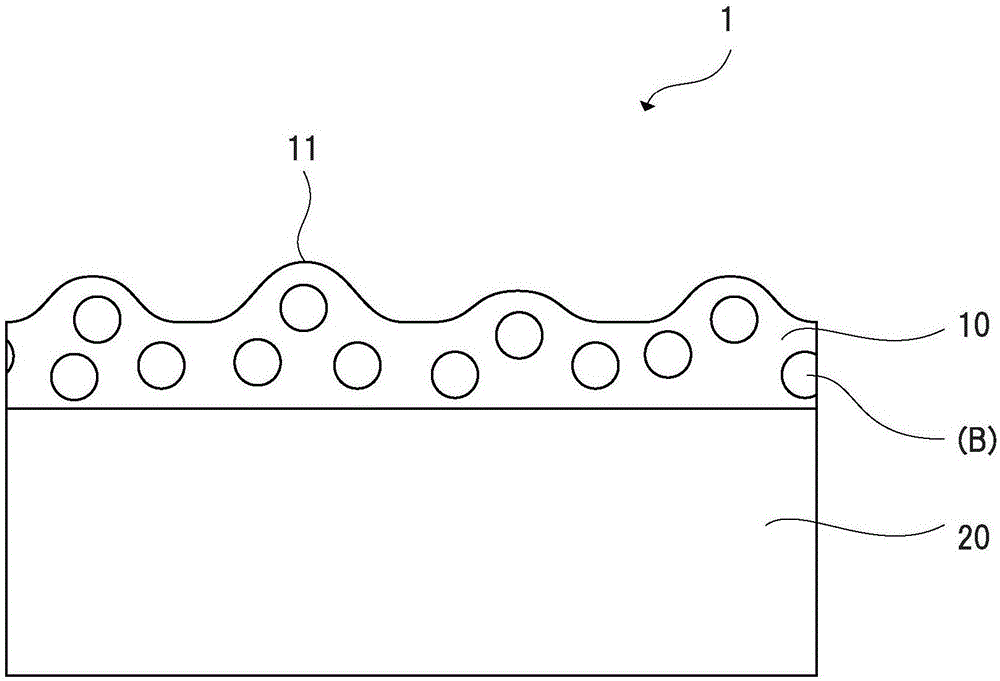

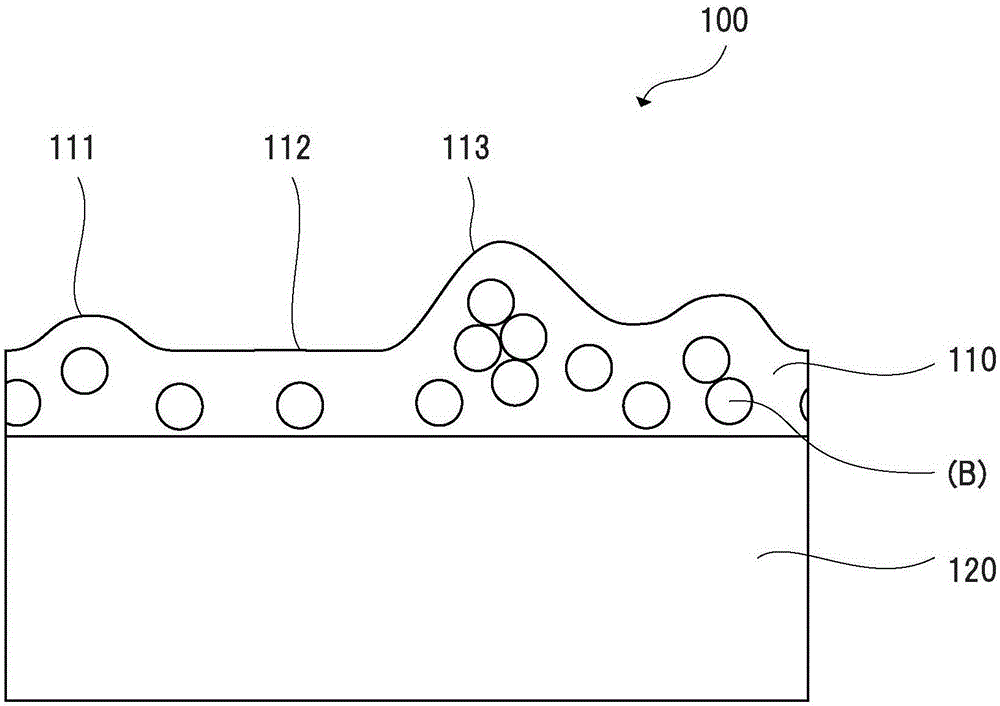

Photocurable resin composition, cured coating film, anti-glare film, method for manufacturing the same, and image display device

A technology of photocurable resin and composition, which is applied in optics, optical components, optical mechanical equipment, etc., can solve the problems of uneven brightness, difficult to take into account anti-glare and uneven brightness, and achieve the effect of less uneven brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

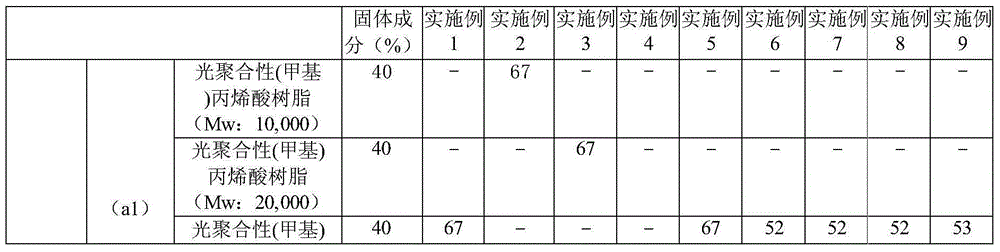

Embodiment 1

[0112] 〔raw material〕

[0113] The used raw materials are as follows.

[0114] As the photopolymerizable component (A), a photopolymerizable (meth)acryloyl group having a weight-average molecular weight (Mw) of 40,000, which has an acrylic group as its main skeleton and a (meth)acryloyl group as a photopolymerizable functional group on the side chain, was used. ) Acrylic resin (a1) ("ACRIT8KX-078" manufactured by Dacheng Fine Chemical Co., Ltd., solid content 40%).

[0115]As the microparticles (B), alumina microparticle-incorporated silicone microparticles (alumina microparticle-incorporated polyorganosilsesquioxane microparticles: solid content 100%) with an average particle diameter of 1.9 μm were used. In addition, the average particle diameter was measured on the following conditions using a laser diffraction particle diameter distribution measuring device ("SALD-2200" by Shimadzu Corporation).

[0116] Dispersion medium: water

[0117] Dispersant: sodium hexametaphosp...

Embodiment 2

[0152] In Example 2, except that a resin having a weight average molecular weight of 10,000 was used as the photopolymerizable (meth)acrylic resin (a1), a photocurable resin composition was prepared in the same manner as in Example 1 to produce Anti-glare film.

Embodiment 3

[0154] In Example 3, except that a resin having a weight average molecular weight of 10,000 was used as the photopolymerizable (meth)acrylic resin (a1), a photocurable resin composition was prepared in the same manner as in Example 1 to produce Anti-glare film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com