Flexible transparent conductive film based on organic polymers and silver nanowires and preparation method thereof

A technology of transparent conductive film and transparent conductive film, applied in nanostructure manufacturing, conductive layer on insulating carrier, nanotechnology, etc., can solve the problems of conductive layer easily damaged by friction, surface is not flat enough, poor adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

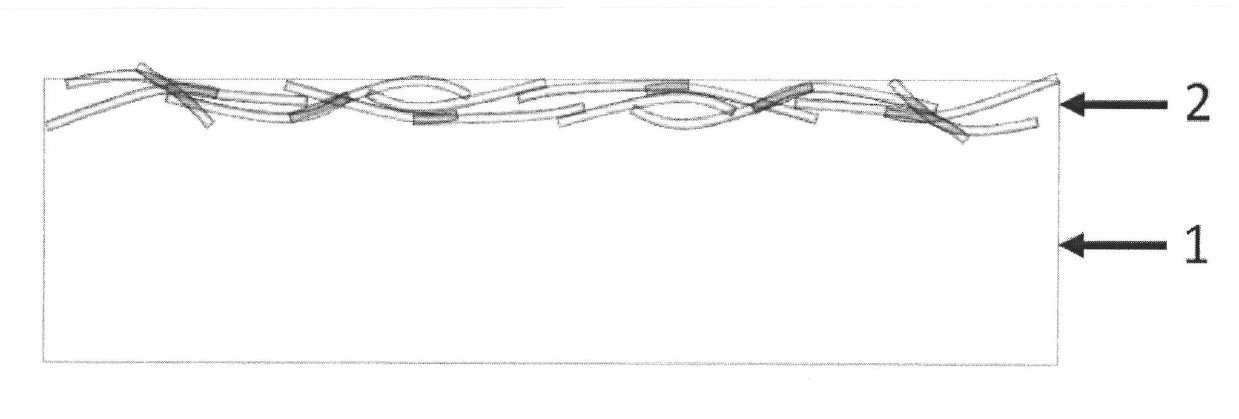

Embodiment 1

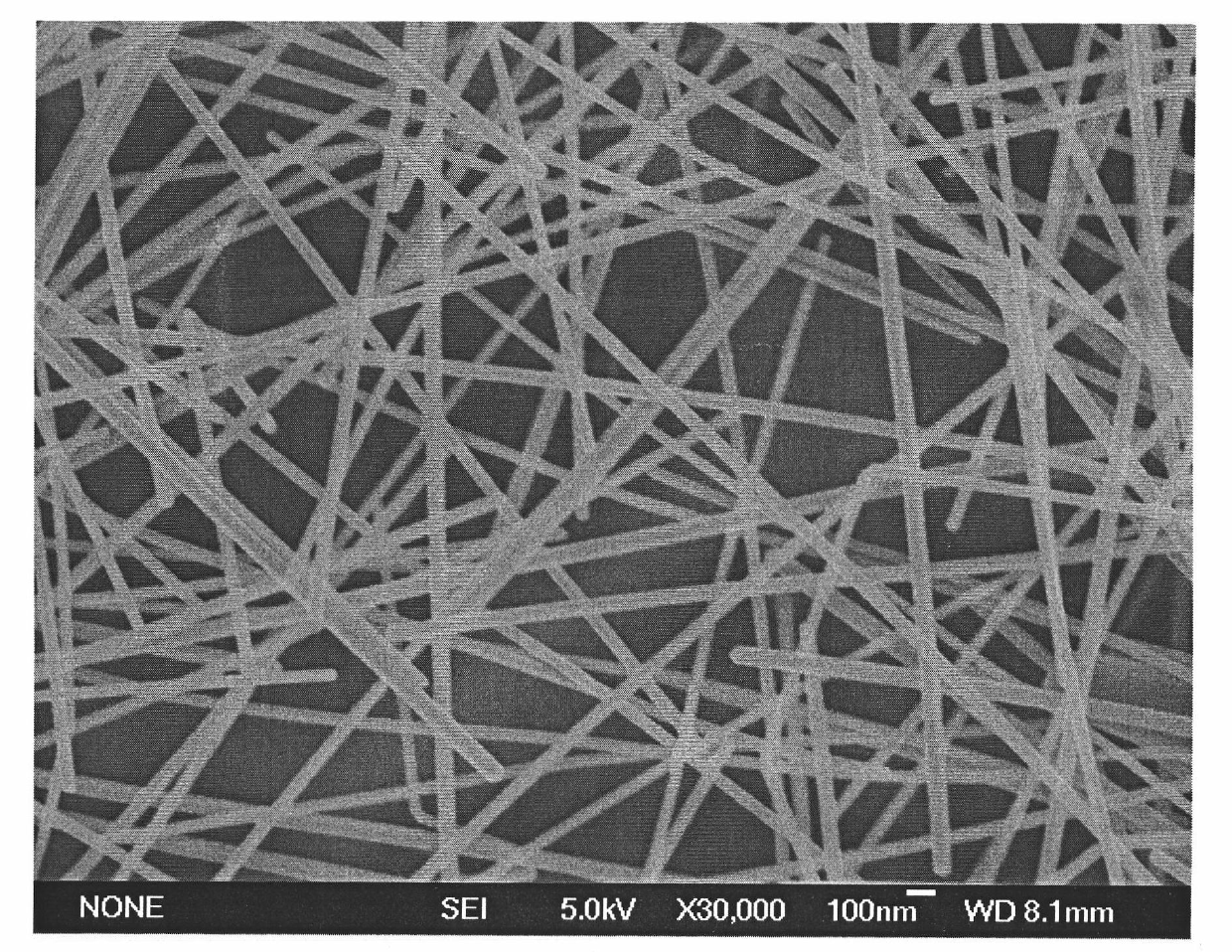

[0020] Ultrasonic cleaned, hydrophilic flat glass is used as the substrate. A specific volume of silver nanowire suspension in water is taken and filtered to form a uniform silver nanowire conductive network structure on the filter membrane. The filter membrane is used as a transfer membrane, pressed tightly on the glass, the filter membrane is removed after heat treatment, and the glass sheet covered with the silver nanowire conductive layer is heat treated at 200° C. for 5-30 minutes. Then on the glass, the spin-coating weight percentage concentration is 10% polyvinyl alcohol (PVA) aqueous solution, forms transparent PVA film after 120 ℃ of drying, has formed good wrapping to the silver nanowire that is positioned at glass and PVA interface, silver nanowire Only the surface in contact with the glass was not wetted by PVA. The conductive layer of PVA and silver nanowires is peeled off from the glass surface to form a flat, firm and transparent conductive film in which silver...

Embodiment 2

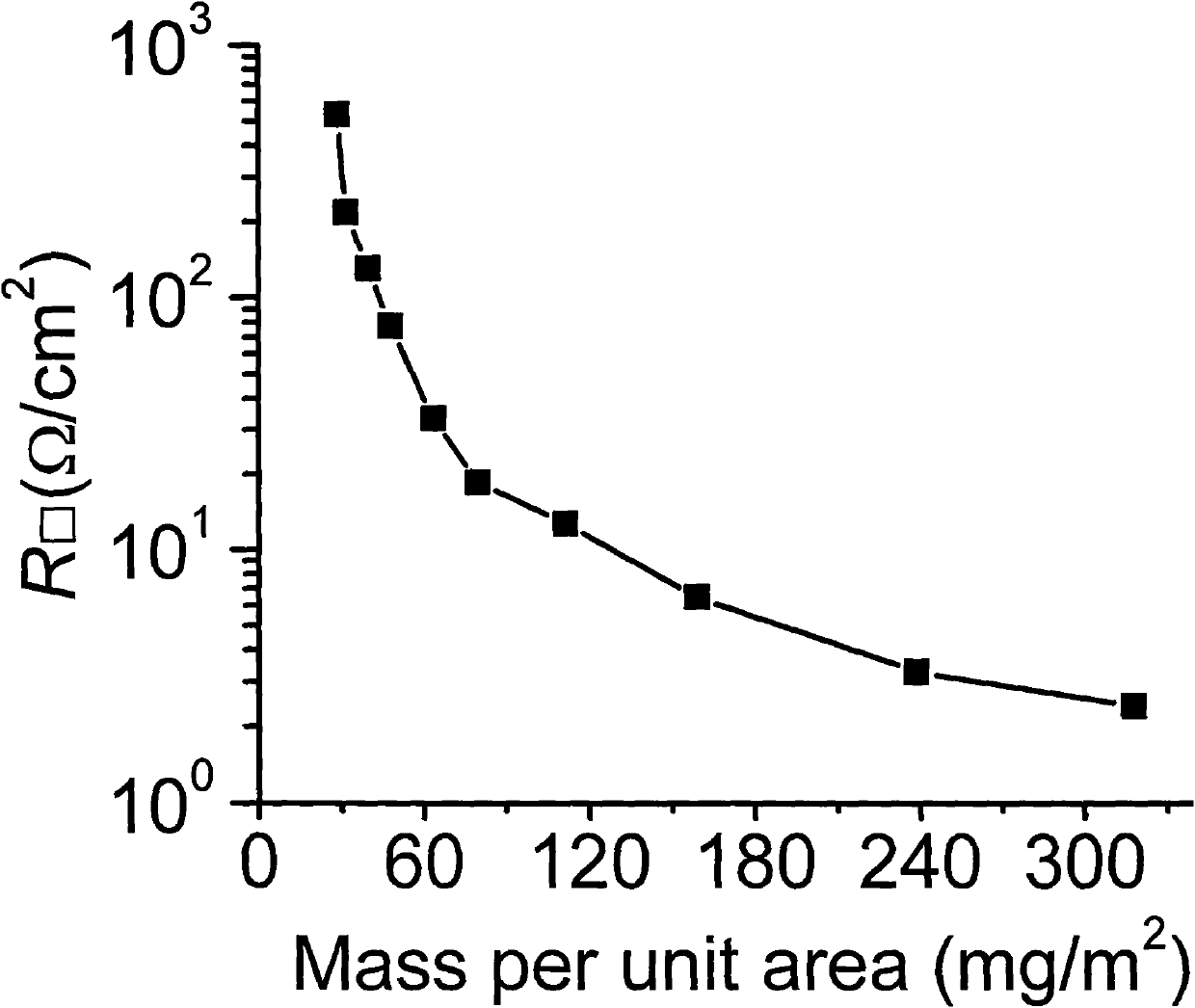

[0023] Using the clean and hydrophilic flat glass cleaned by ultrasonic as the substrate, the ethanol suspension containing silver nanowires was sprayed, and after vacuum drying at room temperature, a uniform continuous conductive network of silver nanowires was formed on the glass, and then heat-treated at 200°C for 5 -30 minutes. Then on the glass, the spin-coating weight percentage concentration is 20% polyvinyl alcohol (PVA) aqueous solution, forms transparent PVA film after 120 ℃ of drying, has formed good wrapping to the silver nanowire that is positioned at glass and PVA interface, silver nanowire Only the surface in contact with the glass was not wetted by PVA. The conductive layer of PVA and silver nanowires is peeled off from the glass surface to form a flat, firm and transparent conductive film in which silver nanowires are semi-embedded in the transparent PVA film surface. The distribution density of the silver nanowires is controlled by spraying the concentration...

Embodiment 3

[0025] Using the clean and hydrophilic flat glass cleaned by ultrasonic as the substrate, the ethanol suspension containing silver nanowires was sprayed, and after vacuum drying at room temperature, a uniform continuous conductive network of silver nanowires was formed on the glass, and then heat-treated at 200°C for 5 -30 minutes. Then cast a polyvinyl alcohol (PVA) aqueous solution with a concentration of 20% by weight on the glass, take it out after vacuum drying at room temperature for 24 hours, and heat-treat it in air at 120° C. for 1 hour. The PVA film and the silver nanowire conductive layer are peeled off from the glass surface to form a flat, firm flexible transparent conductive film in which the silver nanowires are semi-embedded in the transparent PVA film surface layer. The distribution density of the silver nanowires is controlled by spraying the concentration of the silver nanowire suspension and the time of spraying, so as to adjust the sheet resistance and vis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com