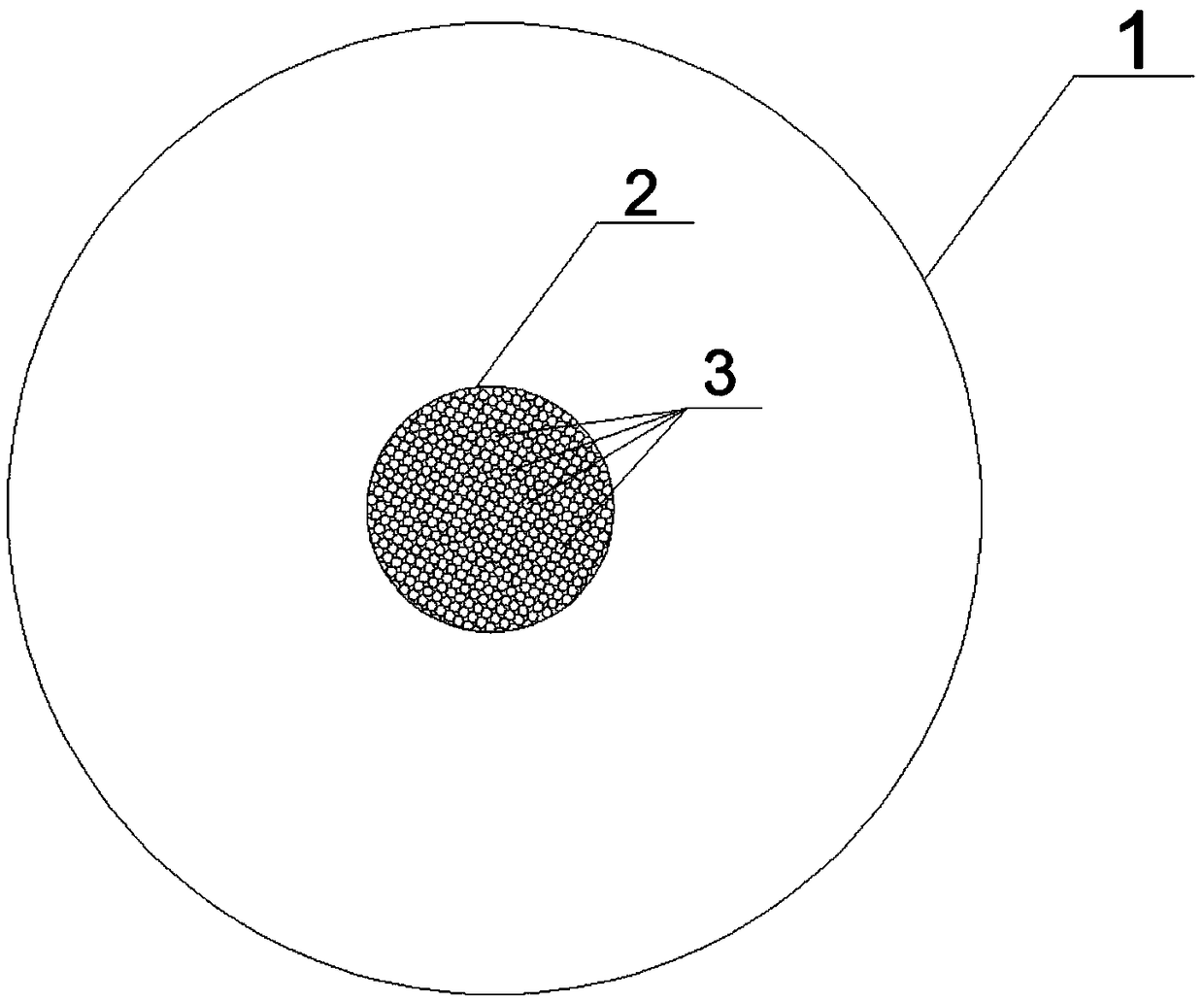

Collimator and manufacturing method

A collimator and substrate technology, applied in the direction of using aperture/collimator, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of limited drilling preparation methods, difficult control of particle movement speed, and unachievable diameter , to achieve the effect of solving the problem of size uniformity and high precision, solving the problem of reliability and stability, and easy to control the accuracy of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

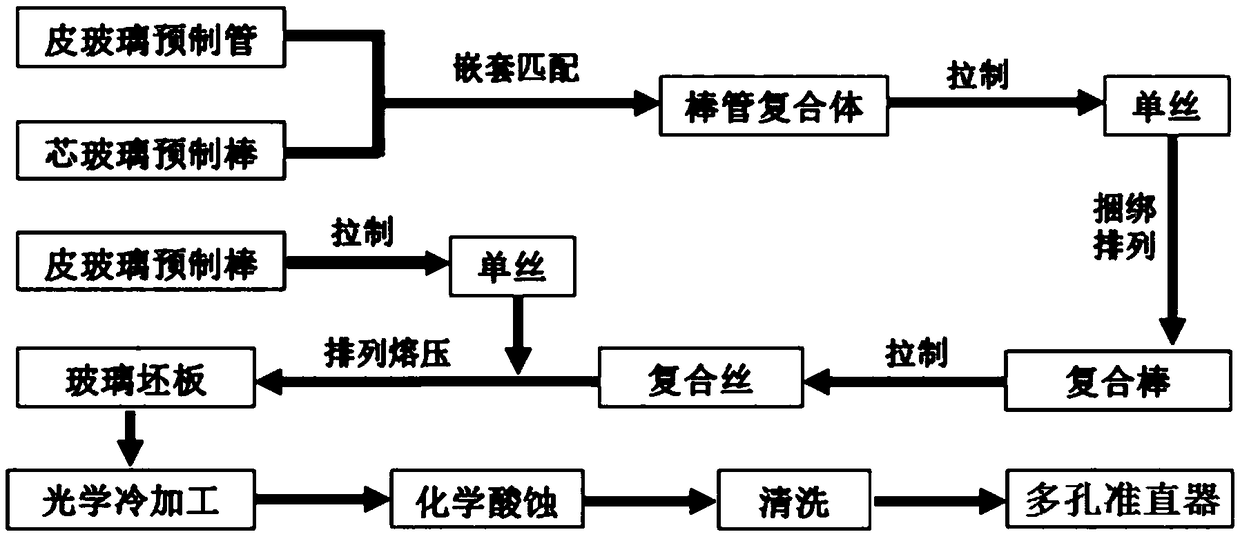

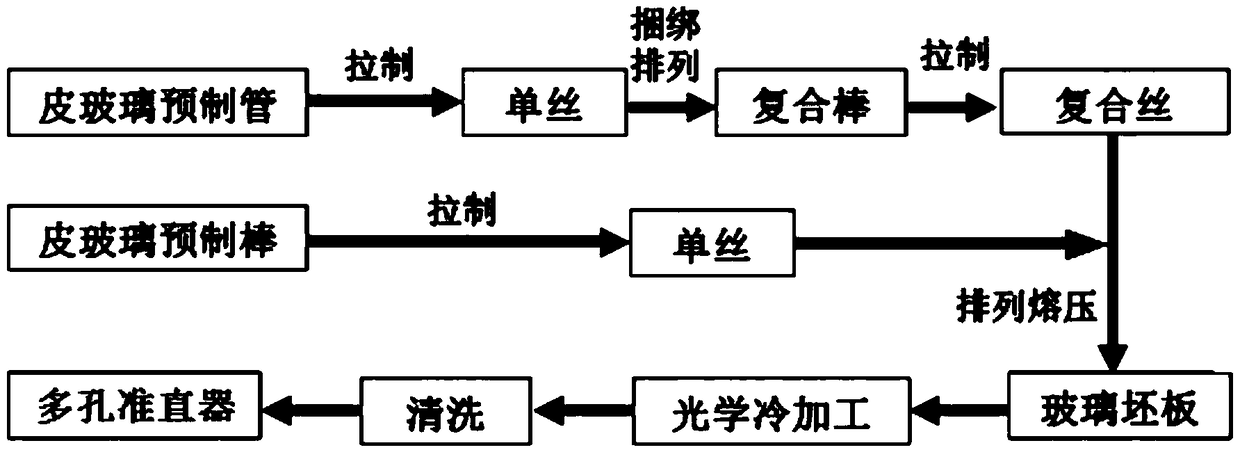

[0118] Adopting the glass rod tube nested drawing method, the preparation method of the collimator comprises the following steps:

[0119] (1) prepare skin glass and core glass respectively, through high temperature melting and clarification, obtain uniform skin glass melt and core glass melt respectively;

[0120] (2) The skin glass melt is mechanically drawn to form a skin prefabricated tube, the skin glass melt is formed into a skin preform through leakage, and the core glass melt is formed into a core preform through leakage;

[0121] (3) Nesting the skin prefabricated tube and the core prefabricated rod to form a tube-rod complex, drawing the tube-rod complex to form a monofilament of the tube-rod complex;

[0122] (4) Arranging the monofilaments of the tube-rod complex, binding them to obtain composite rods, and then drawing them to form composite filaments;

[0123] (5) drawing the skin preform to form a monofilament of the skin preform;

[0124] (6) Arranging the mon...

Embodiment 1

[0224] The collimator in this embodiment has a good match with tungsten material and glass material with similar expansion coefficient.

[0225] The preparation method of the collimator adopts a glass rod tube nested drawing method, comprising the following steps:

[0226] (1) prepare skin glass and core glass respectively:

[0227] Leather glass selection medium expansion glass, in terms of mass percentage, including: SiO 2 : 69.0%, B 2 o 3 : 23.5%, Al 2 o 3 : 3.0%, Li 2 O: 1.5%, Na 2 O: 2.0%, ZrO 2 : 1.0%, its expansion coefficient is 41×10 -7 / °C;

[0228] Core glass corresponding to skin glass, in mass percentage, including: B 2 o 3 : 44.0%, La 2 o 3 : 24.0%, SiO 2 : 23.5%, Al 2 o 3 : 3.5%, Na 2 O: 3.0%, K 2 O: 2.0%, its expansion coefficient is 55×10 -7 / °C;

[0229] (2) The skin glass is formed into a skin prefabricated tube by mechanical drawing. The inner diameter of the skin prefabricated tube is controlled at (32±0.5) mm, and the wall thickness of...

Embodiment 2

[0238] The collimator in this embodiment has a good match with stainless steel material or glass material with similar expansion coefficient.

[0239] The preparation method of the collimator adopts a glass rod tube nested drawing method, comprising the following steps:

[0240] (1) prepare skin glass and core glass respectively:

[0241] Leather glass chooses high-expansion glass, in terms of mass percentage, including: SiO 2 : 63.0%, B 2 o 3 : 4.5%, Al 2 o 3 : 1.0%, BaO: 8.0%, CaO: 4.5%, MgO: 3.0%, Na 2 O: 10.0%, K 2 O: 5.0%, ZrO 2 : 1.0%; its expansion coefficient is 92×10 -7 / °C;

[0242] Core glass corresponding to skin glass, in mass percentage, including: B 2 o 3 : 31.0%, BaO: 21.0%, La 2 o 3 : 28.0%, SiO 2 : 10.0%, Al 2 o 3 : 1.0%, Na 2 O: 5.0%, K 2 O: 4.0%, its expansion coefficient is 102×10 -7 / °C;

[0243] (2) The skin glass is formed into a skin prefabricated tube by mechanical drawing. The inner diameter of the skin prefabricated tube is contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com