1200mw Class Nuclear Power Half-speed Turbo Generator Assembly and Welding Process for Outlet Boxes

A steam turbine generator, assembly and welding technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of narrow operation space, many space positions, small ribs, etc., to ensure molding quality and overall size. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

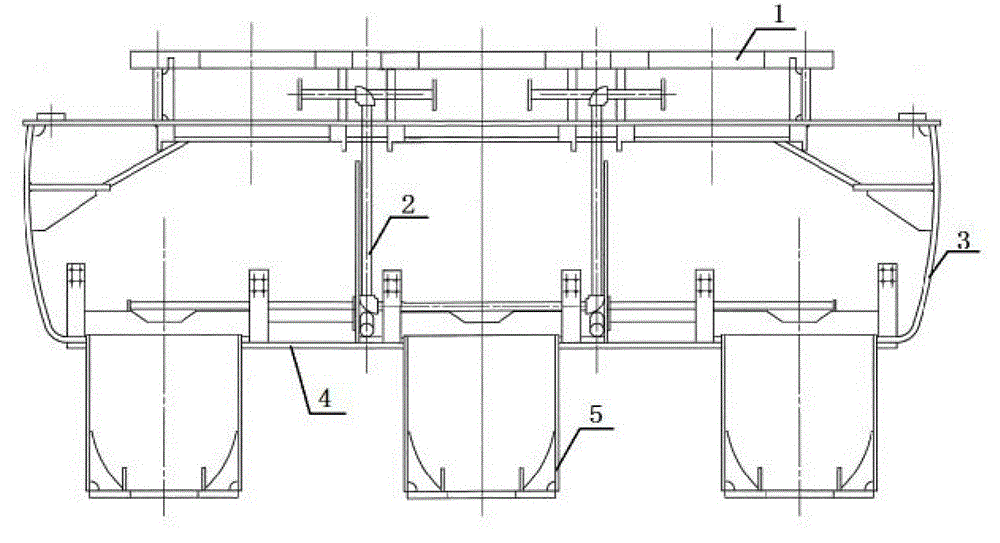

Image

Examples

Embodiment Construction

[0007] The invention is a manufacturing process for ensuring the tear resistance of the upper and lower ring plates of the seat ring and the abrasion resistance of fixed guide vanes. Technical scheme of the present invention is:

[0008] (1) Head cutting: the head material is made of austenitic stainless steel plate 06Cr19Ni10, which is cut by a plasma cutting machine, and a 50mm forming allowance is reserved for one side of the cutting; (2) Head forming: the steel plate is heated in a heating furnace to 1050°C, using a press for hot pressing. The plasma cutting machine removes the forming allowance, and the lathe processes the cutting surface (3) Shell blanking: the shell material is made of austenitic stainless steel plate 06Cr19Ni10, and the plasma cutting machine blanks, and the forming direction reserves 10mm forming allowance; (4) shell Body forming: roll forming at room temperature by rolling plate machine, after forming, fix the shape of the shell with tie bars, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com