Degradable material having multiple sensitive properties, manufacturing method thereof and use thereof

A multi-sensitivity, high-performance technology, used in recombinant DNA technology, introduction of foreign genetic material using vectors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

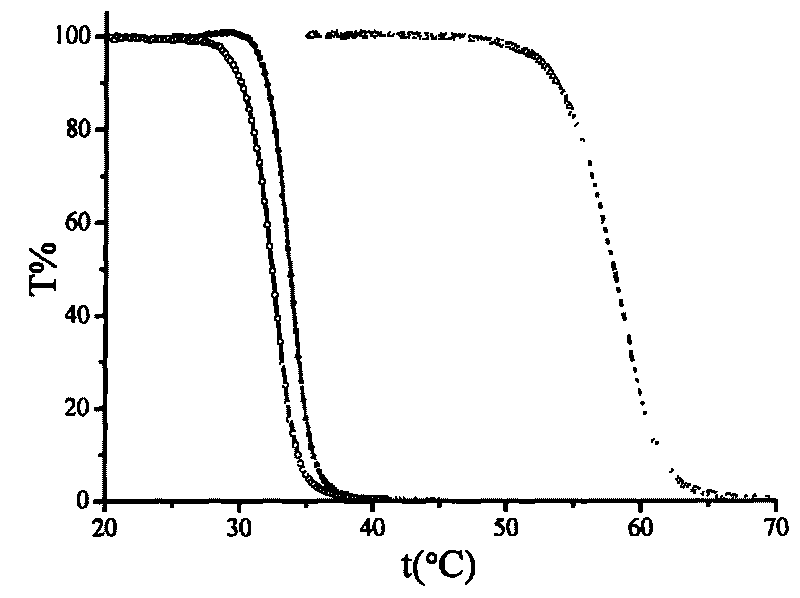

[0041] Example 1: Preparation of the target product with a linear oligoethylenimine with a molecular weight of 423

[0042] According to the concentration of oligoethyleneimine in the organic solvent, the concentration of the substance is 0.2mol / L, and 4.23g of linear oligoethyleneimine with a molecular weight of 423 is dissolved in an equal volume mixed solvent of 50ml of chloroform and methanol, and then respectively according to The ratio of oligoethylenimine to N, N'-bisacryloylcystamine in Table 1, weigh N, N'-bisacryloylcystamine and add it into the reactor, mix well, and heat up to 45°C for reaction For 4 days, spin evaporate, concentrate the reaction solution, settle in 1000ml of n-hexane at 0°C, dry in vacuum, dissolve the obtained crude product in deionized water, and dialyze against deionized water in a dialysis bag with a molecular weight cut off of 3,500 for 4 days , filtered through a G4 sand core funnel, and freeze-dried to obtain the intermediate product cross-...

Embodiment 2

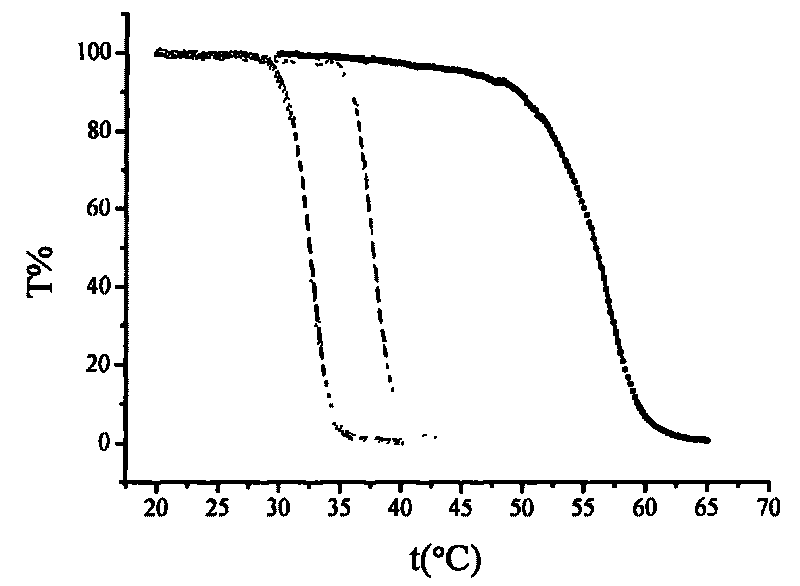

[0046] Embodiment 2: prepare target product with molecular weight being 600 hyperbranched oligoethylenimine

[0047] According to the amount concentration of oligopolyethyleneimine in the organic solvent, the concentration of the substance is 0.2mol / L, and 6g of hyperbranched oligopolyethyleneimine with a molecular weight of 600 is dissolved in an equal-volume mixed solvent of 50ml chloroform and methanol, and then respectively according to The ratio of oligoethylenimine to N,N'-bisacrylcystamine in Table 2, weigh N,N'-bisacrylcystamine and add it to the reactor, mix well, and heat up to 45°C for reaction For 4 days, spin evaporate, concentrate the reaction solution, settle in 1000ml of n-hexane at 0°C, and vacuum-dry. G4 sand core funnel was filtered and freeze-dried to obtain the intermediate product cross-linked oligoethylenimine. Weigh 0.5g of cross-linked oligoethylene imine and dissolve it in deionized water at 0.02mol / L, and then mix N - Add isopropylacrylamide into t...

Embodiment 3

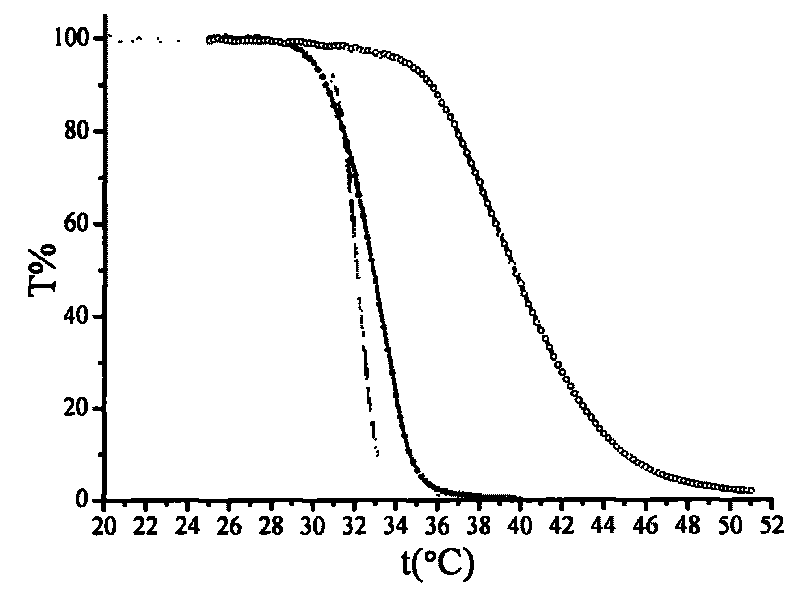

[0051] Example 3: The target product was prepared with a hyperbranched oligoethylenimine with a molecular weight of 1800.

[0052] According to the amount concentration of oligopolyethyleneimine in the organic solvent, the concentration of the substance is 0.1mol / L, and 9g of hyperbranched oligopolyethyleneimine with a molecular weight of 1800 is dissolved in an equal-volume mixed solvent of 50ml chloroform and methanol, and then respectively according to The ratio of oligoethylenimine to N,N'-bisacryloylcystamine in Table 3, weigh N,N'-bisacryloylcystamine and add it to the reactor, mix well, and heat up to 45°C for reaction For 4 days, spin evaporate, concentrate the reaction solution, settle in 1000ml of n-hexane at 0°C, and vacuum-dry. G4 sand core funnel was filtered and freeze-dried to obtain the intermediate product cross-linked oligoethylenimine. Weigh 0.5g of cross-linked oligoethylene imine and dissolve it in deionized water at 0.02mol / L, and then mix N - Add isopr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com