Thermostable low radiation composite film glass and its production technology

A composite film and low-radiation technology, applied in the field of glass, can solve problems such as unsatisfactory performance, inconsistent optical performance, and insufficient protection, and achieve reduced glass heat loss, reduced air-conditioning energy consumption, and good thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

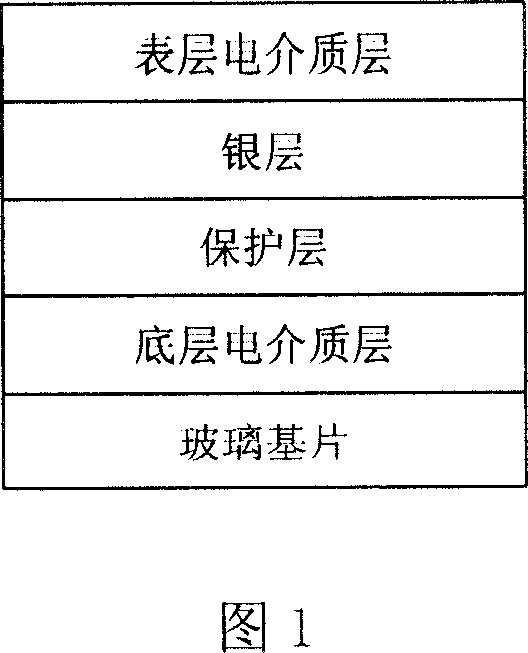

[0025] As shown in Figure 1, this embodiment is a thermally stable low-emissivity composite film glass with a single silver layer structure, which is successively provided with a bottom dielectric layer composed of aluminum nitride, made of stainless steel or nickel-chromium alloy Or their partial oxide or partial nitride protective layer, silver layer and surface dielectric layer composed of aluminum nitride or aluminum oxide, that is, the film structure is glass substrate / bottom dielectric layer / protective layer / silver layer / Surface dielectric layer. Among them, the thickness of the aluminum nitride bottom dielectric layer can be any value between 40-55nm; the thickness of stainless steel, nickel-chromium alloy or their partial oxide or partial nitride protective layer can be any value between 1-10nm. A value; the thickness of the silver layer can take any value between 10 and 18nm; when the surface dielectric layer is made of aluminum nitride, the thickness can take any va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com