Phosphor powder and preparation method thereof and luminescent device

A technology for light-emitting devices and phosphors, which is applied in the fields of light-emitting materials, semiconductor devices, chemical instruments and methods, can solve the problems of reducing the excitation efficiency of phosphors and increasing production costs, and achieves ultra-high color rendering index, high quantum efficiency, Efficient lighting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The present embodiment 1 proposes a kind of preparation method of fluorescent powder, comprises the following steps:

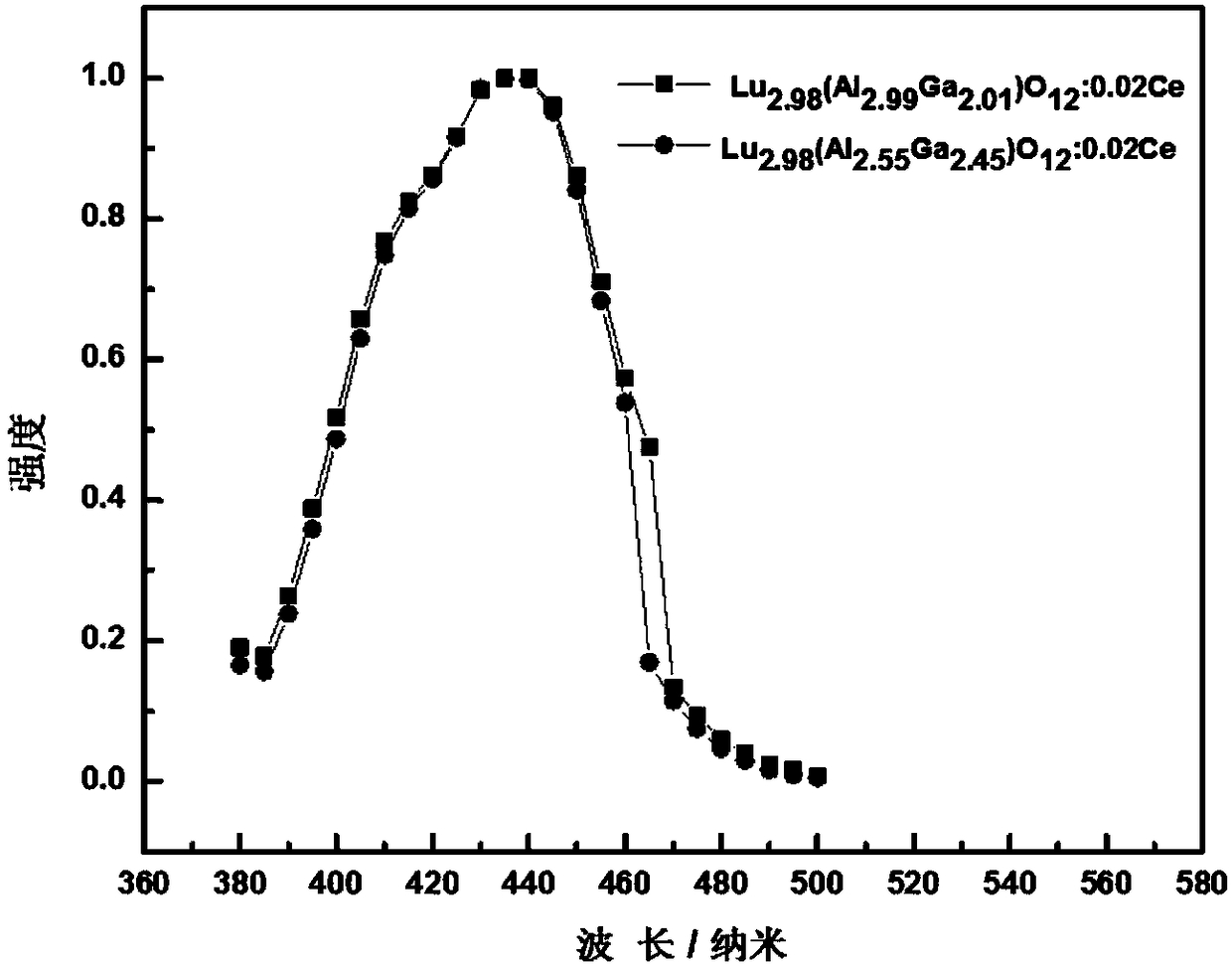

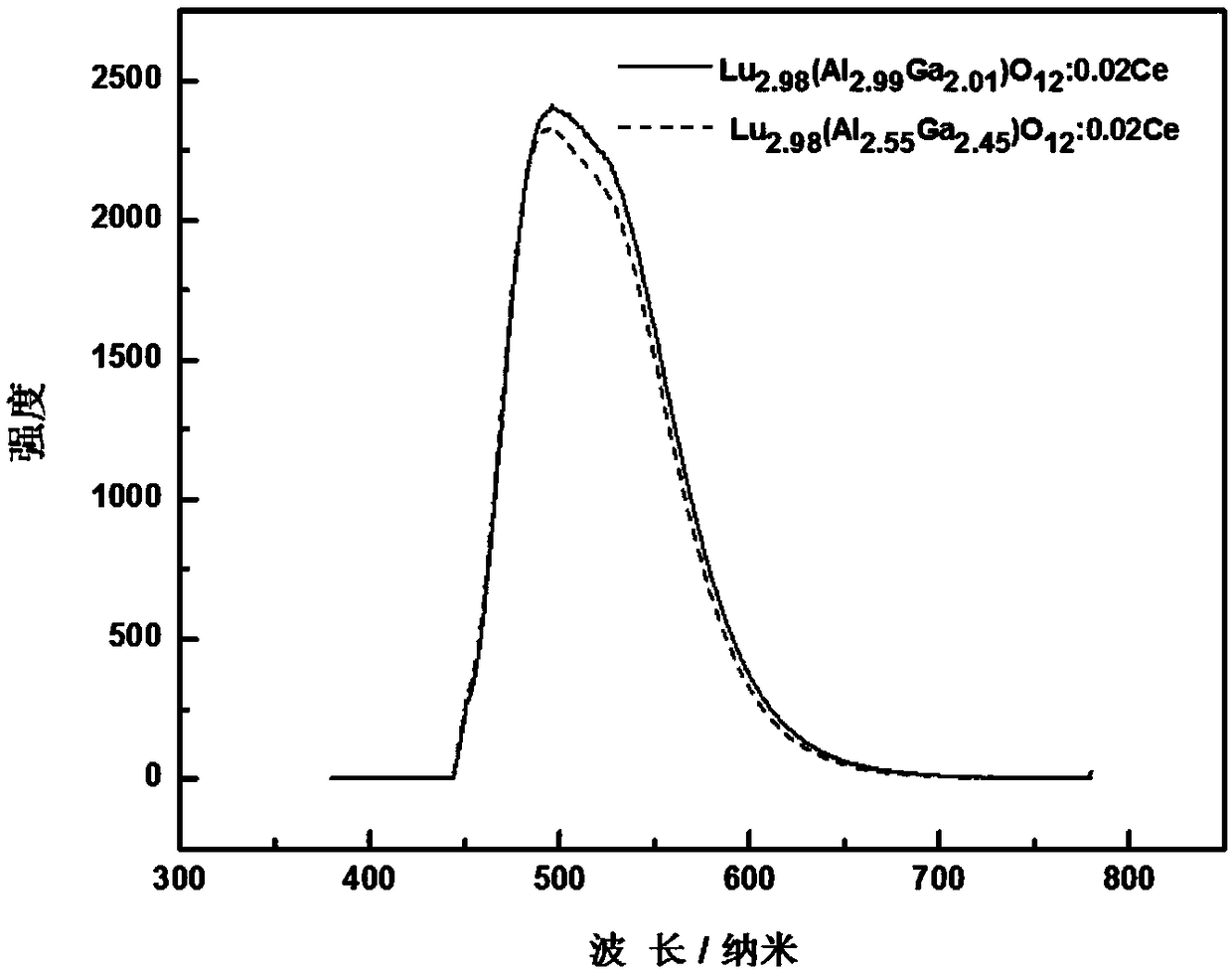

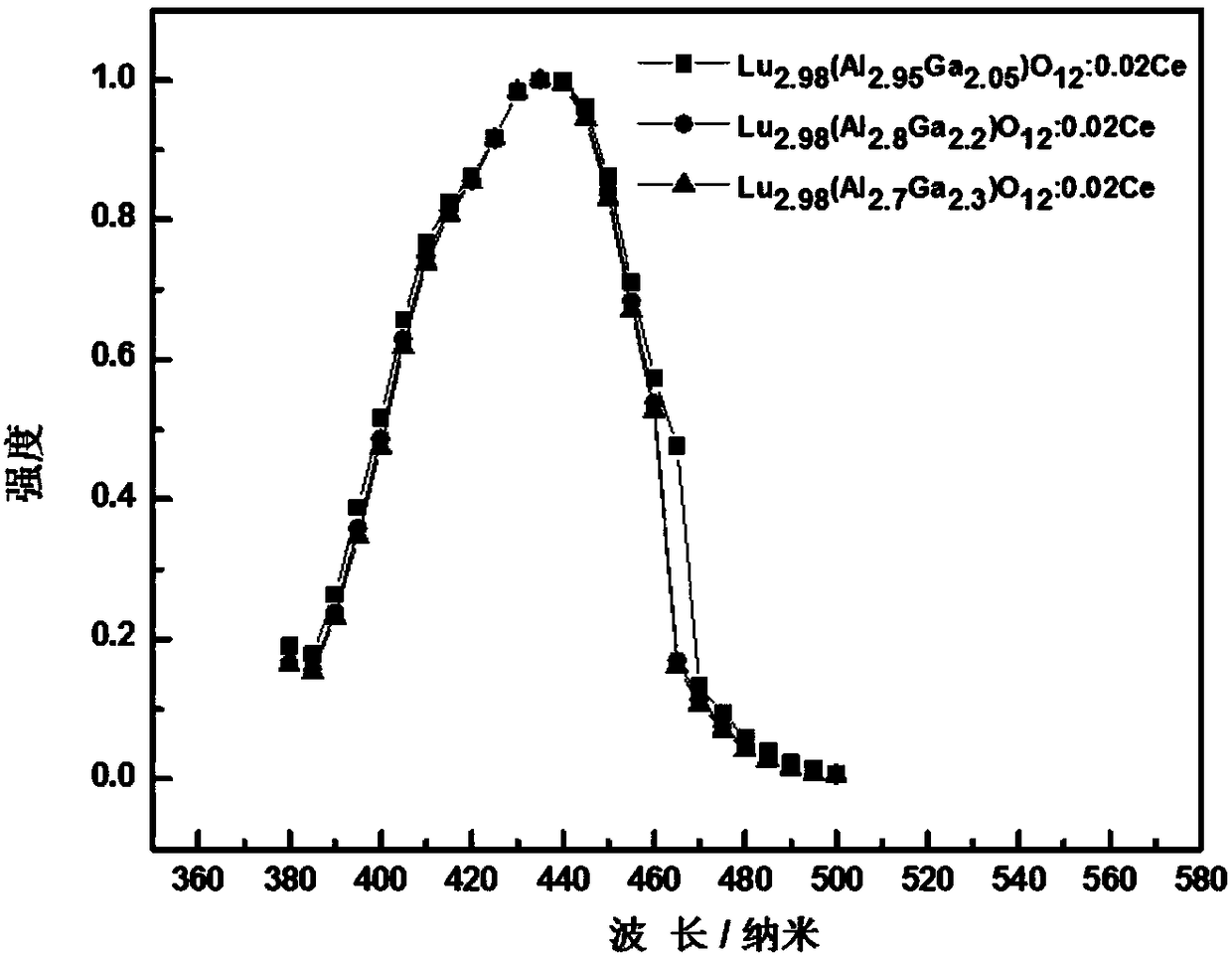

[0060] According to the chemical composition of the fluorescent powder proposed by the present invention, including Lu 2.98 (Al 2.99 Ga 2.01 )O 12 :0.02Ce, Lu 2.98 (Al 2.95 Ga 2.05 )O 12 :0.02Ce, Lu 2.98 (Al 2.8 Ga 2.2 )O 12 :0.02Ce, Lu 2.98 (Al 2.7 Ga 2.3 )O 12 :0.02Ce, Lu 2.98 (Al 2.55 Ga 2.45 )O 12 : 0.02Ce, etc., according to the stoichiometric ratio (ie mole percentage) of cations in the corresponding chemical composition, respectively weigh Lu 2 o 3 、Al 2 o 3 , Ga 2 o 3 and CeO 2 Raw materials, the raw materials are powder materials, and the purity of the raw materials is chemically pure, with Lu 2 o 3 (purity 99.99%), Al 2 o 3 (purity 99.99%), Ga 2 o 3 (purity 99.99%), CeO 2 (purity 99.99%) is preferred; further, the raw material in the present embodiment 1 also includes fluxing agent BaF 2 and / or BaCl 2 , the flu...

Embodiment 2

[0069] Another fluorescent powder proposed in Example 2 and its preparation method has Lu 3-x (Al 2.95 Ga 2.05 )O 12 : the composition of xCe, wherein preferably x satisfies: 0.015≤x≤0.025, and in this embodiment 2, x takes values: 0.015, 0.02, 0.025 respectively. Prepare Example 2 according to the same preparation method as Example 1 to obtain Lu 3-x (Al 2.95 Ga 2.05 )O 12 : Phosphor powder of xCe series.

[0070] Similarly, test the excitation spectrum of the fluorescent powder prepared in Example 2, such as Figure 7 Lu2.985(Al2.95Ga2.05)O12:0.015Ce, Lu2.98(Al2.95Ga2.05)O12:0.02Ce and Lu2.975(Al2.95Ga2.05)O12:0.025 of Example 2 of the present invention The excitation spectrum diagram of the Ce phosphor shows that under the action of excitation light with a wavelength of about 440nm, the phosphor powder prepared in Example 2 has the strongest fluorescence intensity; Figure 8 For the emission spectrum of the phosphor powder prepared in this embodiment, the emission ...

Embodiment 3

[0073] Another kind of fluorescent powder and its preparation method proposed in this embodiment 3 have Lu 3-x (Al 2.8 Ga 2.2 )O 12 : The composition of xCe, in present embodiment 3, x values respectively: 0.018,0.022. Adopt the preparation method identical with embodiment 1 to carry out preparation embodiment 3, obtain Lu 3-x (Al 2.8 Ga 2.2 )O 12 :xCe phosphor.

[0074] Test the excitation spectrum of the fluorescent powder prepared in this embodiment 3, such as Figure 9 As shown, under the action of excitation light with a wavelength of about 445nm, the phosphor powder prepared in Example 3 has the strongest fluorescence intensity; Figure 10 The emission spectrum of the fluorescent powder prepared in Example 3 has an emission peak wavelength of 490-500 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color rendering index | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com