High-surface quality ferrite stainless steel plate and manufacturing method thereof

A ferritic and stainless steel technology is applied to a ferritic stainless steel plate, which can solve the problems of low roughness and achieve the effects of low roughness, good formability and high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

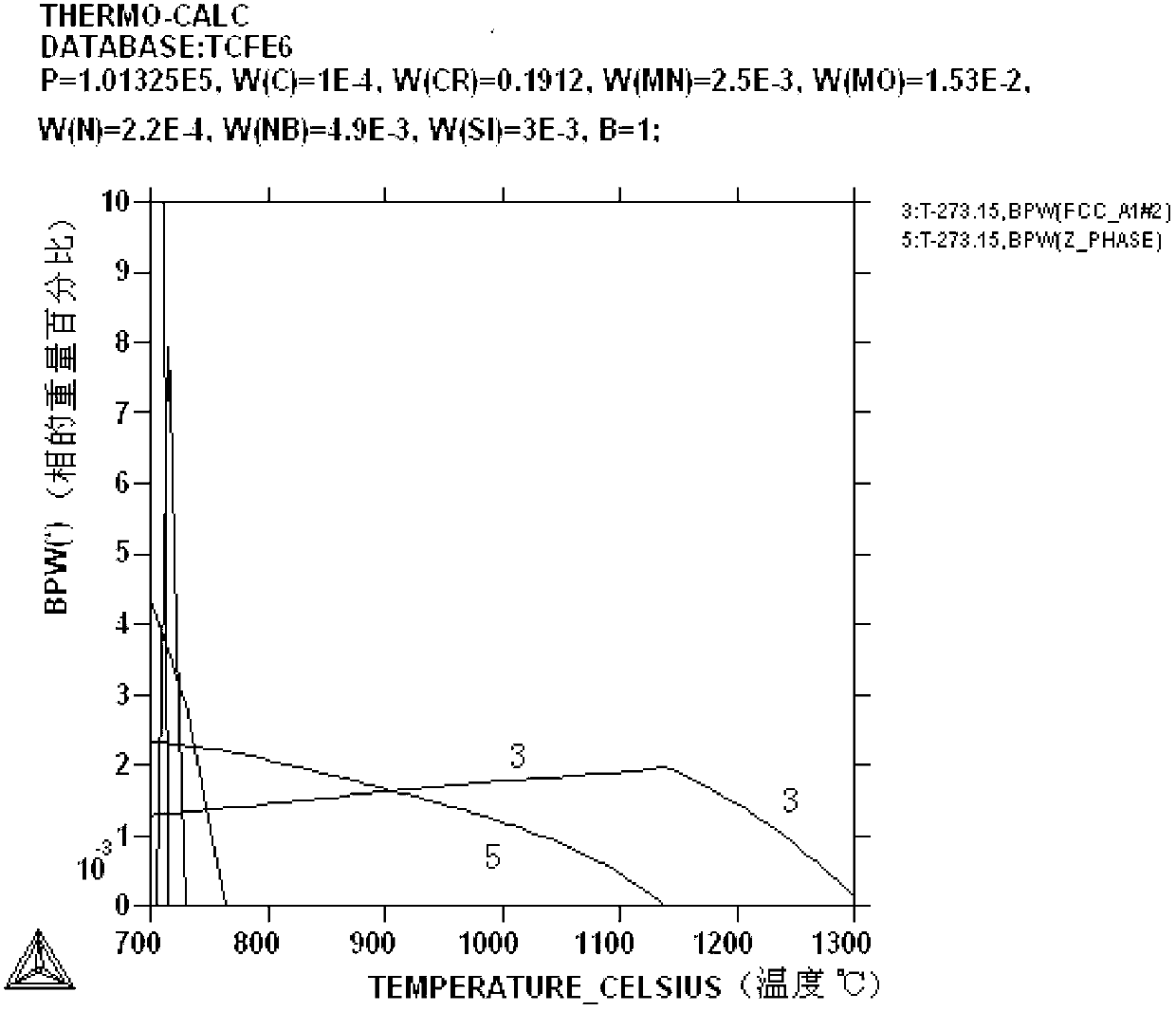

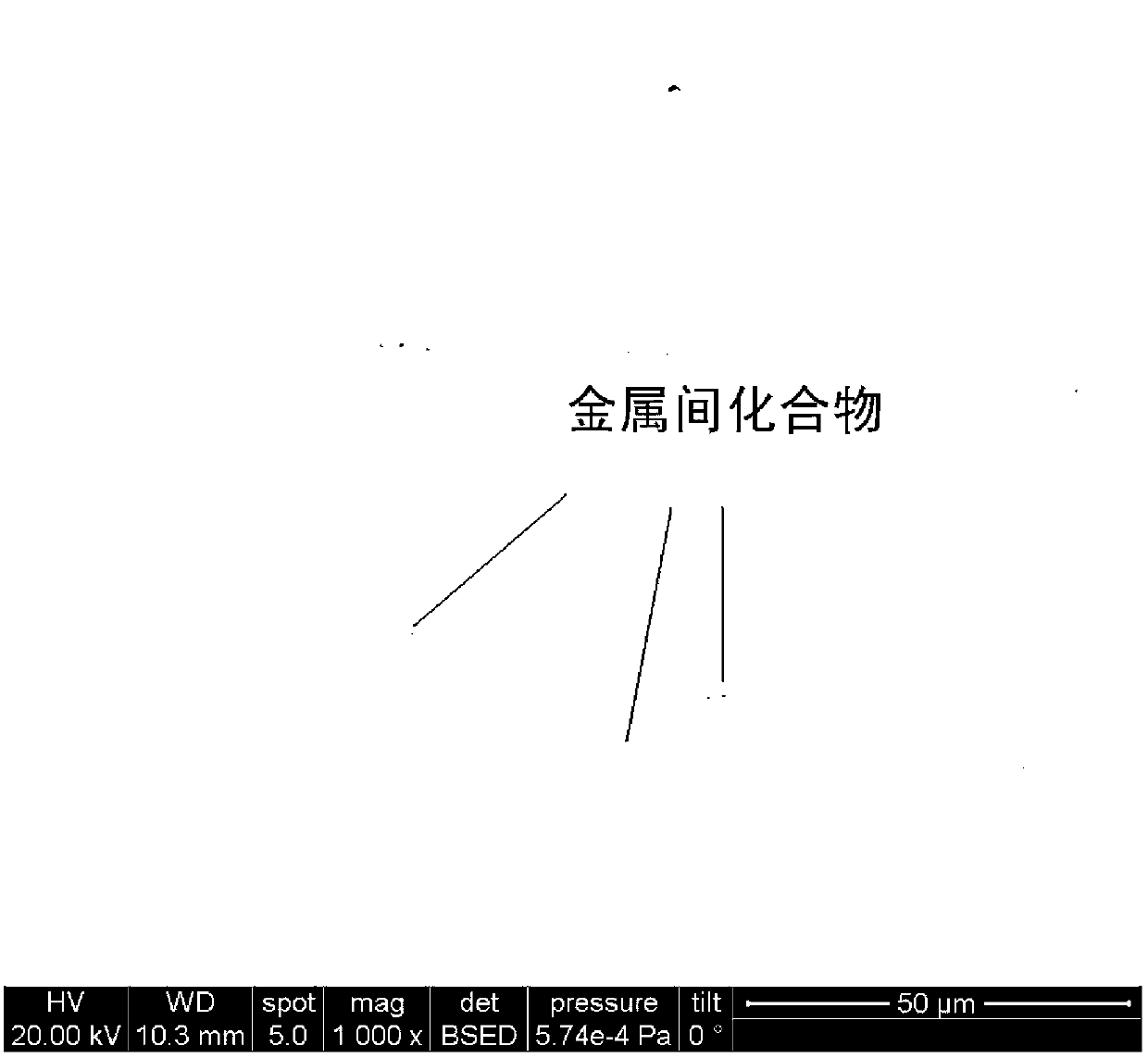

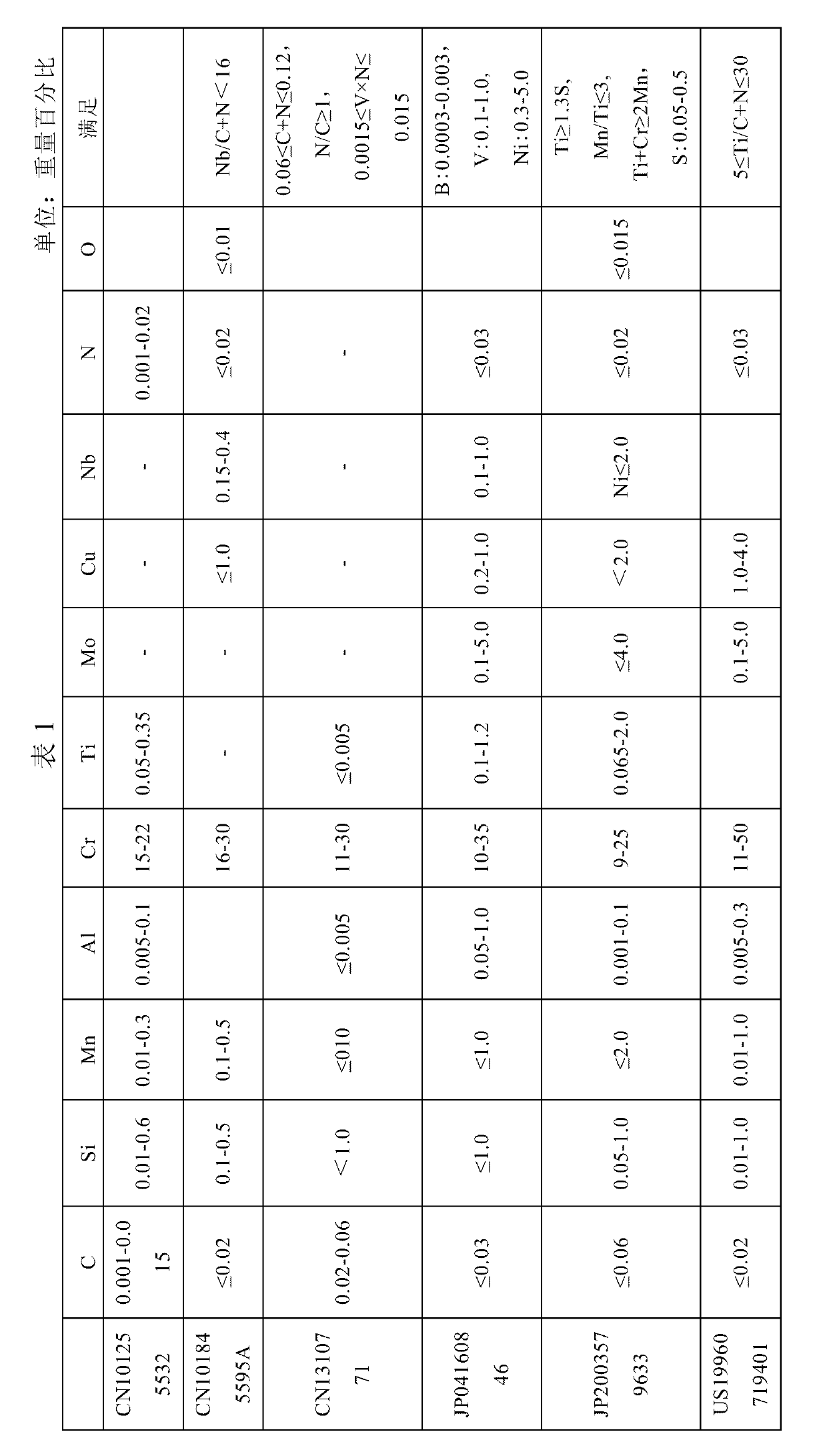

[0047] Table 3 shows the weight percentages of the chemical components of the high surface quality ferritic stainless steel sheets of the following examples. Smelted according to the ratio of chemical composition shown in Table 3, after casting, surface grinding, heating, hot rolling, annealing, pickling, first cold rolling and BA bright annealing, second cold rolling and BA bright annealing After cooling and flattening, the ferritic stainless steel plate with high surface quality is obtained; wherein, during the smelting process, the slag basicity is controlled at 1.5 to 2.5, and ferrosilicon or silicon-manganese alloy with an aluminum content of less than 1.0% is used for deoxidation; In the pouring step, the steel ingot or billet is poured under the condition of no oxidation protection; in the surface grinding step, the obtained steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com