High-flame-retardancy high-heat-resistance MPP pipe and preparation method thereof

A technology with high heat resistance and high flame retardancy is applied in the field of MPP pipes with high flame retardancy and high heat resistance and its preparation, and can solve the problems of flame retardancy, stable heat resistance, poor mechanical strength and the like of power protection pipes. Achieve the effect of reducing surface gloss, improving low temperature impact toughness and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

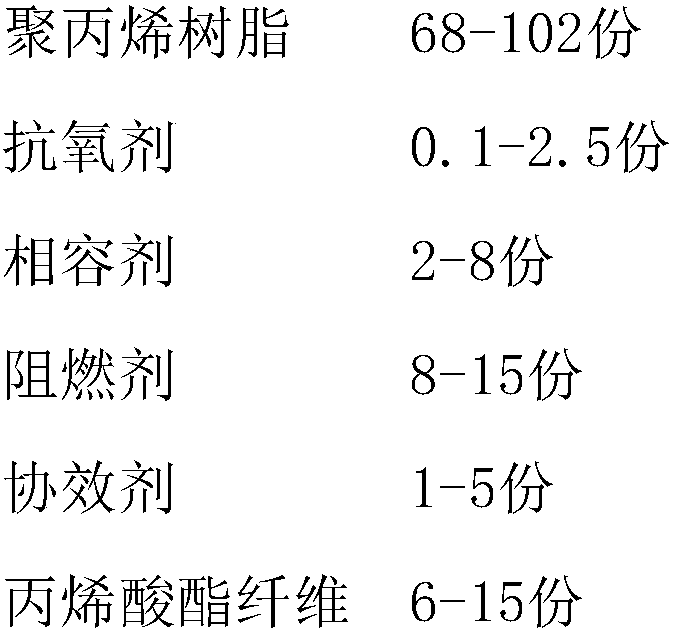

[0035] A high flame-retardant and high heat-resistant MPP pipe, the MPP pipe includes the following raw materials by weight:

[0036]

[0037] The heat-resistant filler is a mixture of calcium carbonate, lignocellulose and magnesium silicide in a weight ratio of 3:3:2.

[0038] The antioxidant is a mixture of primary antioxidant and secondary antioxidant in a weight ratio of 1:1.5, and the primary antioxidant is β-(3,5-di-tert-butyl-4-hydroxybenzene base) n-octadecyl propionate, and the secondary antioxidant is tris(2,4-di-tert-butylphenyl) phosphite.

[0039] The compatibilizer is styrene-acrylonitrile copolymer grafted with glycidyl methacrylate.

[0040] The flame retardant is 1,2-bis(tetrabromophthalimide)ethane and / or brominated epoxy resin.

[0041] The synergist is zinc borate.

[0042] The MPP pipe also includes 10 parts of an impact modifier, and the impact modifier is a styrene-butadiene-styrene copolymer.

[0043] The MPP pipe also includes 1 part of lubrican...

Embodiment 2

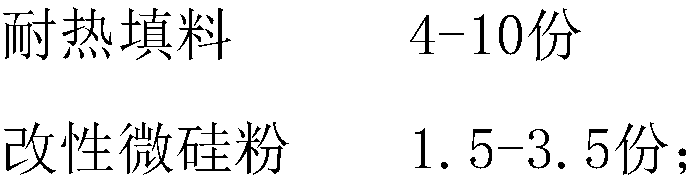

[0049] A high flame-retardant and high heat-resistant MPP pipe, the MPP pipe includes the following raw materials by weight:

[0050]

[0051] The heat-resistant filler is a mixture of calcium carbonate, lignocellulose and magnesium silicide in a weight ratio of 5:4:1.8.

[0052] The antioxidant is a mixture of primary antioxidant and secondary antioxidant in a weight ratio of 1:1.8, and the primary antioxidant is tetrakis[β-(3,5-di-tert-butyl-4- Hydroxyphenyl) propionic acid] pentaerythritol ester, the secondary antioxidant is tris (2,4-di-tert-butylphenyl) phosphite.

[0053] The compatibilizer is hydrogenated styrene-butadiene-styrene copolymer grafted with glycidyl methacrylate.

[0054] The flame retardant is decabromodiphenylethane, 2,4,6-tribromophenol, poly(2,6-dibromophenylene ether).

[0055] The synergist is at least one of zinc stearate, talcum powder and iron oxide.

[0056] The MPP pipe also includes 11 parts of an impact modifier, and the impact modifier i...

Embodiment 3

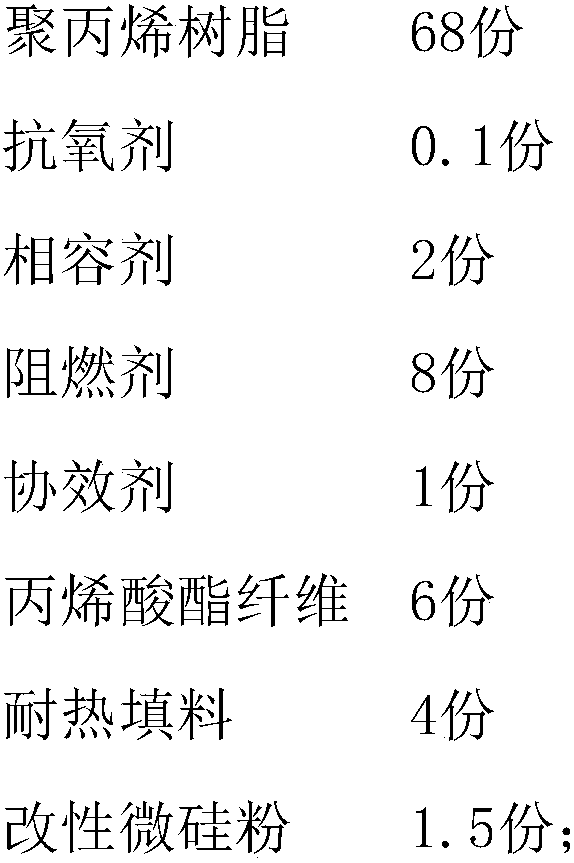

[0063] A high flame-retardant and high heat-resistant MPP pipe, the MPP pipe includes the following raw materials by weight:

[0064]

[0065]

[0066] The heat-resistant filler is a mixture of calcium carbonate, lignocellulose and magnesium silicide in a weight ratio of 7.5:5:1.5.

[0067] The antioxidant is a mixture of primary antioxidant and secondary antioxidant in a weight ratio of 1:2, and the primary antioxidant is β-(3,5-di-tert-butyl-4-hydroxybenzene base) n-octadecyl propionate, and the secondary antioxidant is bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite.

[0068] The compatibilizer is a block copolymer of polydiorganosiloxane and polycarbonate.

[0069] The flame retardant is at least one of decabromodiphenyl ether, tetrabromobisphenol A and brominated polystyrene.

[0070] The synergist is antimony trioxide.

[0071] The MPP pipe also includes 12 parts of an impact modifier, and the impact modifier is nitrile rubber with an acrylonitrile unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com