Scratching-resistant low-gloss polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of polymer modification and processing, can solve the problems of high gloss of materials, and achieve the effects of low surface gloss, simple preparation process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

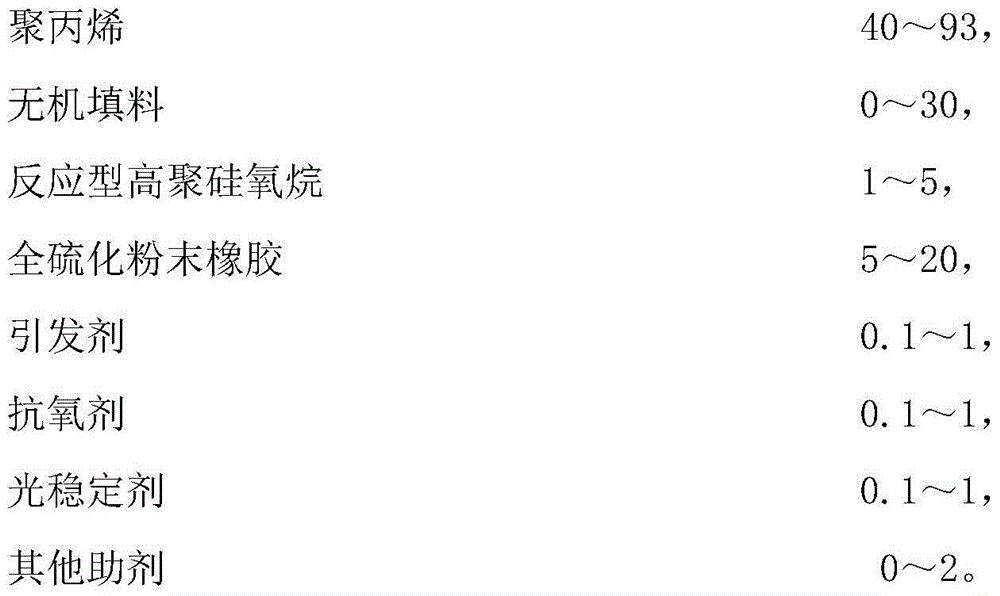

Method used

Image

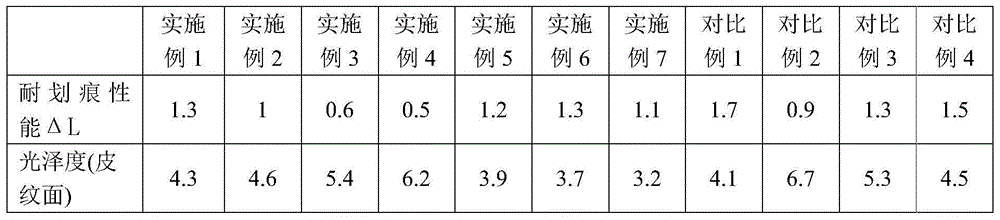

Examples

Embodiment Construction

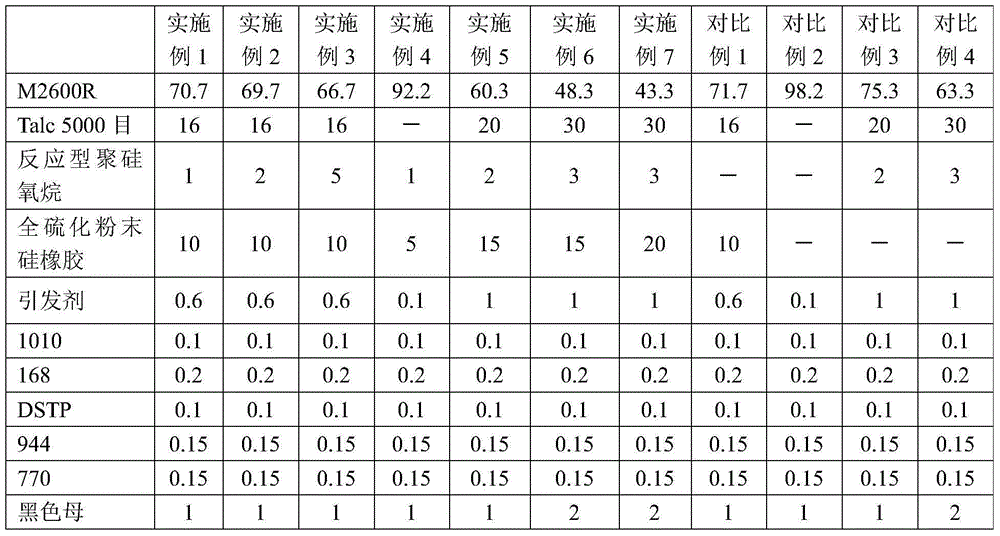

[0027] Below in conjunction with embodiment, the present invention is described in further detail:

[0028] In the composite material formulations of Examples and Comparative Examples, the polypropylene used is a copolymerized polypropylene produced by Shanghai Petrochemical, and the trade name is M2600R. The inorganic filler is 5000-mesh talc powder with an average particle size of 2.5 microns. The reactive polysiloxane used is self-made polysiloxane containing vinyl reactive functional groups, and the molecular weight is between 10,000 and 30,000. The fully vulcanized powder rubber used is fully vulcanized powdered silicone rubber produced by Beijing Research Institute of Chemical Industry, the brand name VP-601 has an average particle size of 0.05-1 μm, and its gel content is 60 wt% or higher. The initiator used is 1,3,5-triisopropylbenzene from Shanghai Ethyl Chemical Co., Ltd., with a molecular formula of C15H24 and a molecular weight of 204.4. Used main antioxidant is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com