Polypropylene-use matting agent masterbatch, and preparation method and application thereof

A technology of matting agent and polypropylene, which is applied in the field of plastic modification, can solve the problems of reducing the surface gloss of polypropylene blended modified materials, and the matting effect is not ideal, and achieves the effect of simple and reliable use method and reducing surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

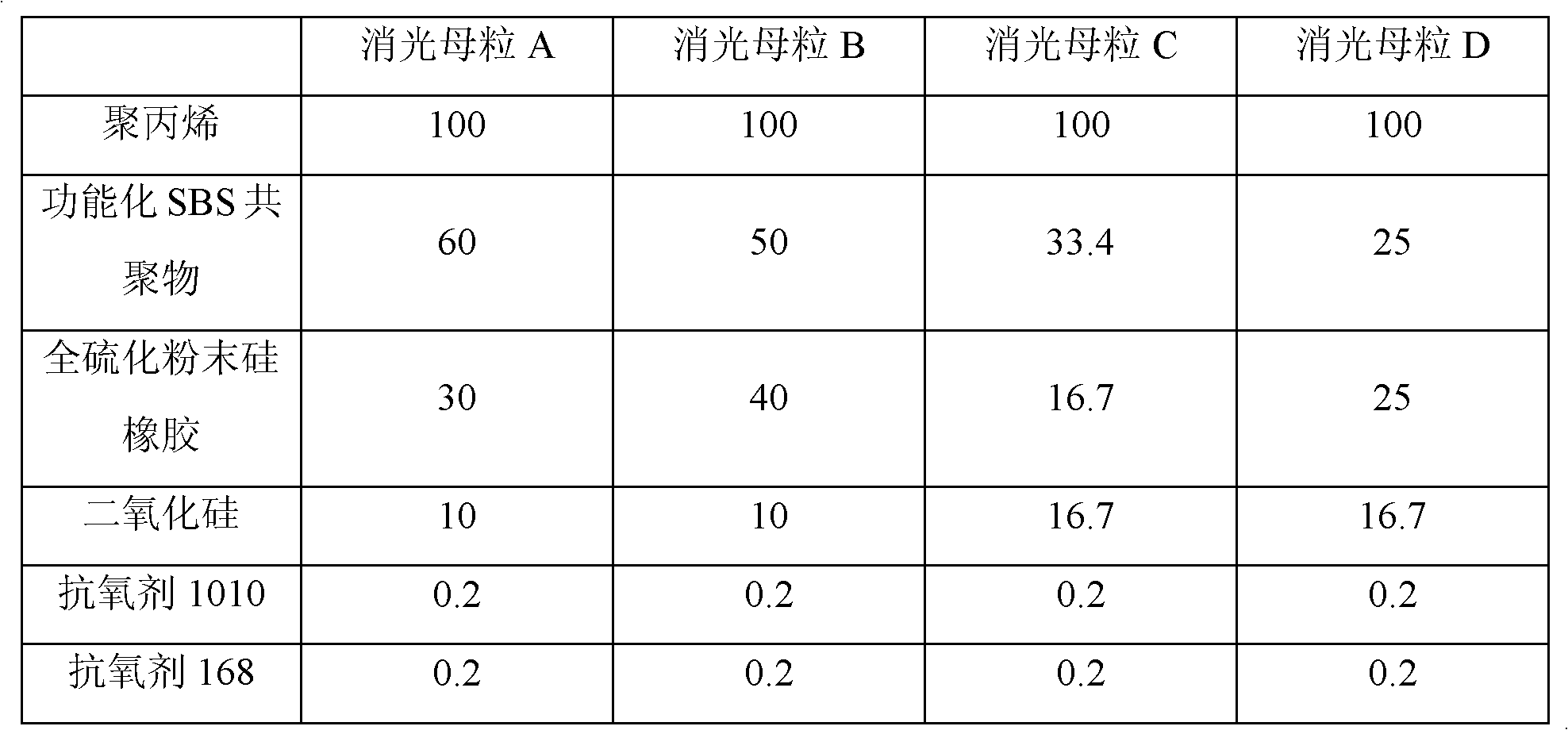

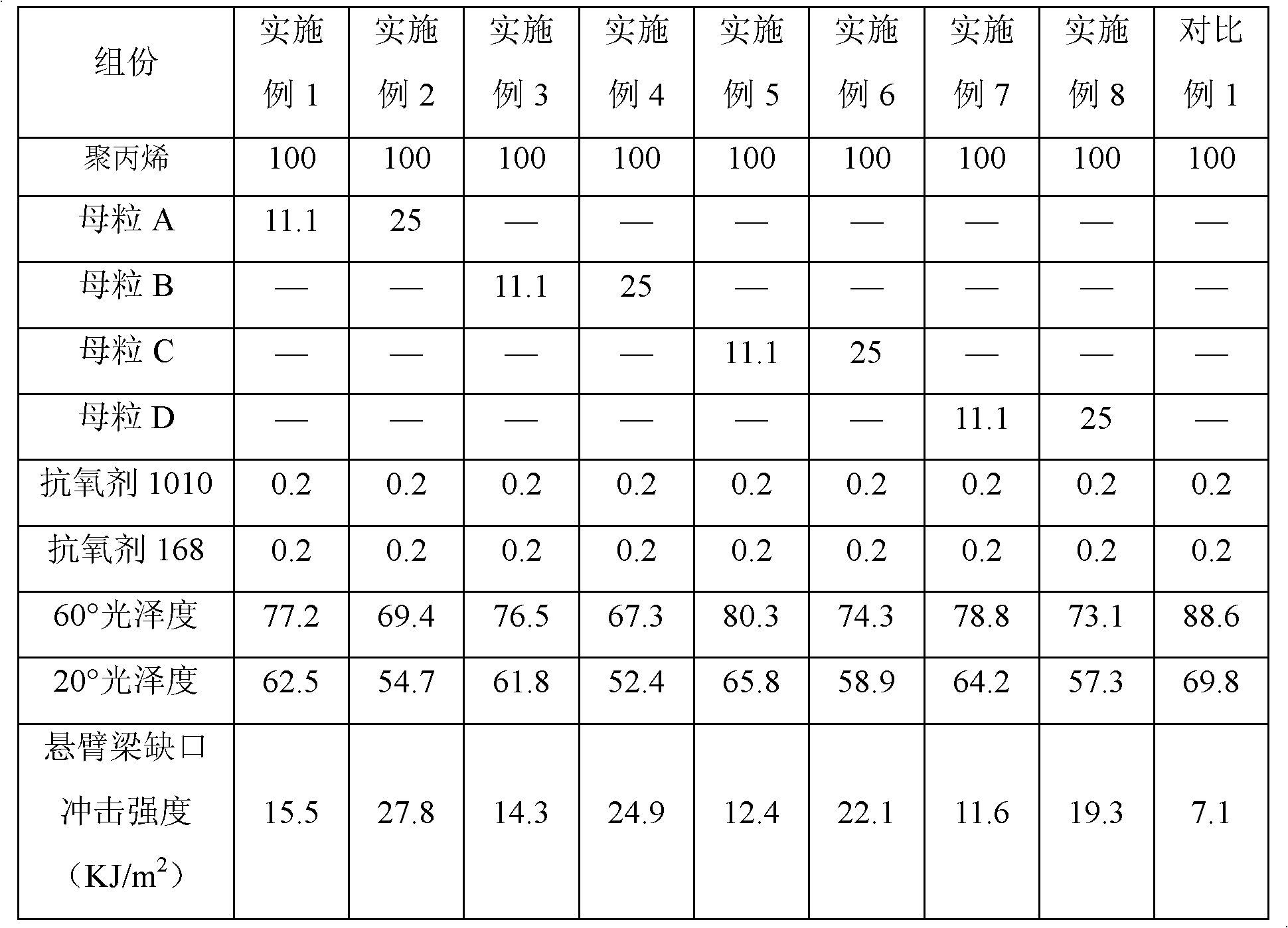

Embodiment 1~8

[0036] Polypropylene (K9020, Sinopec Yanshan Branch), matting agent masterbatch (A-D) and antioxidant (Irganox 1010 and Irgafos 168 compounded at a weight ratio of 1:1, Swiss Ciba Specialty Chemical Co., Ltd.) were put into In a high-speed mixer, stir at a speed of 300 rpm for 3 minutes to fully mix the components. Subsequently, the above-mentioned mixed material is extruded and granulated through a twin-screw extruder within the range of 190°C to 220°C to obtain a low-gloss polypropylene modified material. Its specific formula is shown in Table 2, wherein the content of each component is calculated in parts by weight.

[0037] The extruded pellets were dried in a constant temperature oven at 95°C for 6 hours, and then injected into standard specimens at a temperature of 210°C to 225°C to test the matting properties and notched Izod impact strength. The test of Izod notched impact strength is tested according to the international standard test method ISO180. Gloss test using...

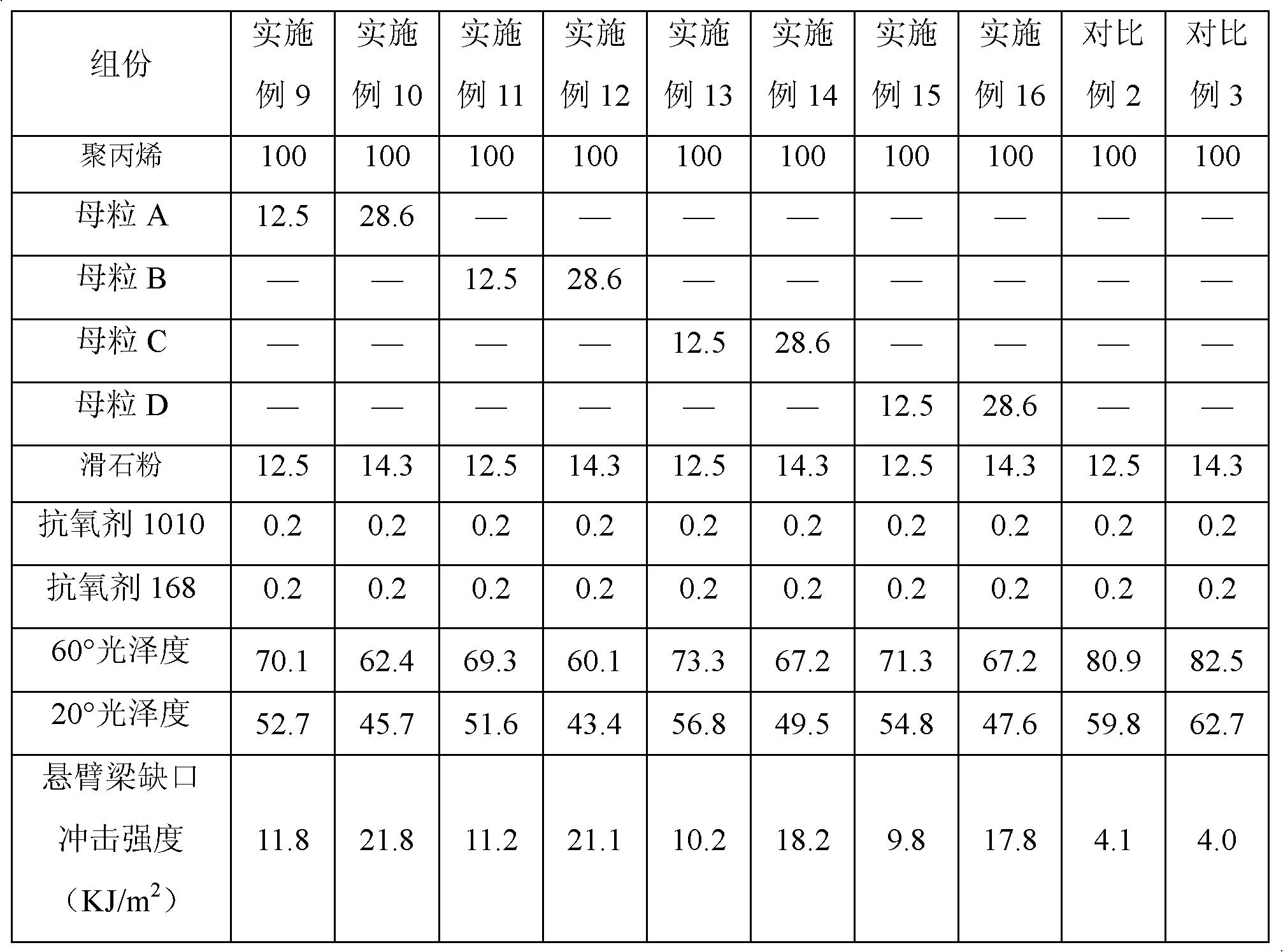

Embodiment 9~16

[0039] Polypropylene (K9020, Sinopec Yanshan Branch), matting agent masterbatch (A-D), ultrafine talc powder (average particle size 6.5 μm, Liaoning Haicheng Powder Material Co., Ltd.) and antioxidants (Irganox 1010 and Irgafos 168 is compounded at a weight ratio of 1:1 (Swiss Ciba Specialty Chemical Co., Ltd.) into a high-speed mixer, and stirred at a speed of 300 rpm for 3 minutes to fully mix the components evenly. Subsequently, the above-mentioned mixed material is extruded and granulated through a twin-screw extruder within the range of 190°C to 220°C to obtain a low-gloss polypropylene modified material. Its specific formula is shown in Table 3, wherein the content of each component is calculated in parts by weight.

[0040] The extruded pellets were dried in a constant temperature oven at 95°C for 6 hours, and then injected into standard specimens at a temperature of 210°C to 225°C to test the matting performance. Gloss test using JFL-BZ 20 ° 60 ° 85 ° intelligent glos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com